Improving your vacuum pump's performance involves more than just the pump itself; it requires a systemic approach. For liquid-sealed pumps, such as a circulating water vacuum pump, the most direct way to achieve a deeper vacuum is by reducing the temperature of the working fluid. Colder water has a lower vapor pressure, which directly dictates the ultimate vacuum your pump can achieve.

A vacuum pump's performance is not solely defined by its specifications but is a direct result of the entire system's integrity. The ultimate vacuum level is often limited by physical constraints like fluid temperature and system leaks, not just the pump's mechanical capability.

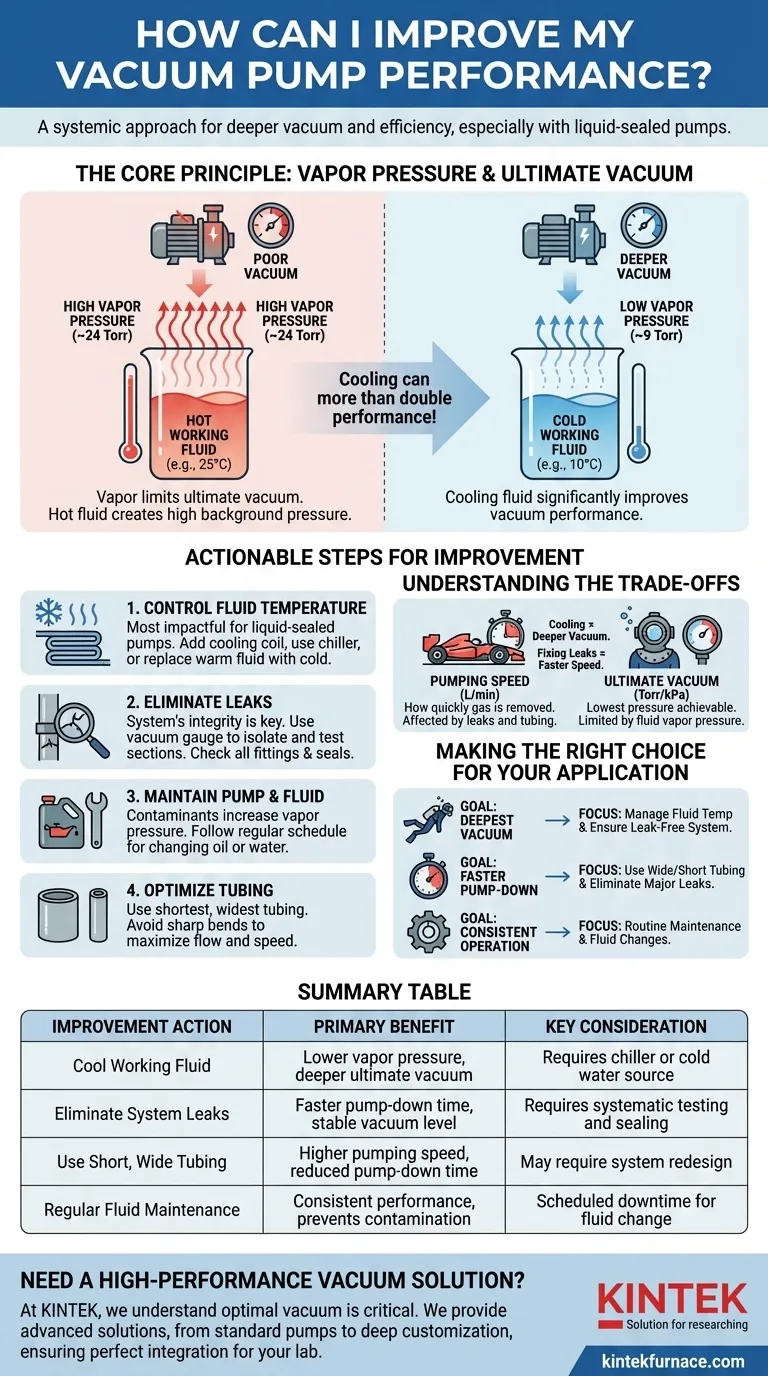

The Core Principle: Vapor Pressure and Ultimate Vacuum

To truly improve performance, you must first understand the fundamental limitation of any vacuum system that uses a liquid sealant, such as water or oil.

Why Temperature Is the Limiting Factor

The deepest vacuum a liquid-sealed pump can create is limited by the vapor pressure of that liquid. The pump cannot remove the vapor that its own sealing liquid is constantly emitting into the vacuum space.

A liquid's vapor pressure is a measure of its tendency to evaporate. This pressure is highly dependent on temperature.

The Physics of Vapor Pressure

As you increase the temperature of a liquid, its molecules gain energy. More molecules will have enough energy to escape from the liquid's surface and become a gas (or vapor).

This vapor exerts its own pressure. A pump trying to create a vacuum must work against this self-generated pressure. Hotter water creates a higher background pressure, resulting in a poorer (higher pressure) vacuum.

The Practical Impact on Performance

For a typical water-jet or liquid-ring pump, warm tap water (25°C / 77°F) has a vapor pressure of about 24 Torr. This means the pump, no matter how powerful, can't achieve a vacuum deeper than 24 Torr.

However, if you cool that same water to 10°C (50°F), its vapor pressure drops to around 9 Torr. By simply cooling the water, you can more than double your pump's vacuum performance without any other changes. The specifications of your pump, such as an ultimate vacuum of 2 kPa (~15 Torr), are typically measured under ideal, cool-water conditions.

Actionable Steps for Performance Improvement

You can systematically enhance your vacuum pump's output by addressing a few critical areas.

1. Control Your Working Fluid Temperature

This is the most impactful step for a liquid-sealed pump.

If your pump has a reservoir, as described in the reference specifications, ensure the water remains cool. On long runs, this water will heat up due to the energy of pumping. Consider adding a cooling coil to the reservoir or periodically replacing the warm water with fresh, cold water.

2. Hunt Down and Eliminate Leaks

A vacuum system is only as good as its weakest seal. Even a microscopic leak can overwhelm a pump's capacity and prevent it from reaching its ultimate vacuum.

Isolate sections of your vacuum setup and use a vacuum gauge to monitor the pressure rise over time. A rapid rise indicates a significant leak in that section. Listen for hissing sounds and check every fitting, hose, and seal.

3. Maintain the Pump and Fluid

The working fluid can become contaminated with solvents or other materials from the process. Contaminants can increase the fluid's overall vapor pressure, degrading performance.

Follow a regular schedule for changing the pump's water or oil. This ensures the fluid's properties remain consistent and predictable.

4. Optimize Your Tubing and Connections

The path from the pump to your chamber matters. Gas molecules have to travel through this path to be removed.

Use the shortest and widest tubing possible for your application. Avoid sharp bends and unnecessary fittings, as each one restricts flow and slows down the pump-down time.

Understanding the Trade-offs

Improving performance often involves balancing competing factors.

Pumping Speed vs. Ultimate Vacuum

These are two distinct performance metrics. Pumping speed (e.g., L/min) measures how quickly a pump can remove gas from a chamber. Ultimate vacuum (e.g., kPa or Torr) is the lowest possible pressure the pump can achieve.

A pump can have a very high speed but a poor ultimate vacuum, or vice-versa. Fixing a large leak might not change your ultimate vacuum, but it will drastically improve your pump-down time. Cooling the water will primarily improve the ultimate vacuum.

The Limits of Your Pump's Technology

A circulating water vacuum pump is a "roughing" pump. Its ultimate vacuum is physically limited by water's vapor pressure, typically in the range of 15-30 Torr.

If your application requires a deeper vacuum (e.g., below 1 Torr), you will need a different type of pump technology, such as a rotary vane oil pump, often used in series with a high-vacuum pump like a diffusion or turbomolecular pump.

The Cost of Cooling

While cooling the working fluid is highly effective, it introduces complexity and cost. Implementing a laboratory chiller or even a simple ice bath requires resources, energy, and space. You must weigh the performance gain against these operational costs.

Making the Right Choice for Your Application

Tailor your improvement strategy to your specific goal.

- If your primary focus is reaching the deepest possible vacuum: Your top priority is managing the temperature of the pump's working fluid and ensuring a completely leak-free system.

- If your primary focus is faster pump-down times: Concentrate on using wide, short tubing and checking for major leaks that overwhelm the pump's volumetric capacity.

- If your primary focus is consistent, reliable operation: Establish a routine maintenance schedule for changing the working fluid and inspecting all seals and connections.

By systematically addressing your entire vacuum system, you can ensure your pump operates at its maximum potential.

Summary Table:

| Improvement Action | Primary Benefit | Key Consideration |

|---|---|---|

| Cool Working Fluid | Lower vapor pressure, deeper ultimate vacuum | Requires chiller or cold water source |

| Eliminate System Leaks | Faster pump-down time, stable vacuum level | Requires systematic testing and sealing |

| Use Short, Wide Tubing | Higher pumping speed, reduced pump-down time | May require system redesign |

| Regular Fluid Maintenance | Consistent performance, prevents contamination | Scheduled downtime for fluid change |

Need a High-Performance Vacuum Solution Tailored to Your Unique Requirements?

At KINTEK, we understand that achieving optimal vacuum performance is critical for your laboratory's success. Our expertise goes beyond standard pumps to encompass the entire vacuum system.

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions and complementary vacuum systems. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements, ensuring your vacuum system is perfectly integrated for maximum efficiency and performance.

Contact us today via our Contact Form to discuss how we can help you design a vacuum system that delivers superior performance, reliability, and depth for your specific application.

Visual Guide

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

People Also Ask

- How does a high-vacuum pump system facilitate the synthesis of high-quality calcium-based perrhenates? Expert Synthesis

- What is the primary function of the vacuum pump system in the magnesium powder evaporation process? Ensure High Purity & Efficiency

- What are the main technical requirements for vacuum pumps in vacuum sintering furnaces? Ensure Material Purity and Efficiency

- What is the function of vacuum systems and sealing connectors? Mastering Pure and Controlled Chemical Environments

- What materials are used for the heating elements in a vacuum furnace? Choose the Right Element for Your High-Temp Needs