In short, the primary technical requirements for a vacuum pump in a sintering furnace are its ability to reach the necessary operating pressure, its pumping speed, and its robustness to handle the contaminants produced during the process. These three factors work together to ensure material purity, proper densification, and efficient, repeatable production cycles.

The selection of a vacuum pump for sintering is not merely about achieving a deep vacuum. It is fundamentally about engineering a system that can rapidly evacuate a furnace, manage a high-volume flow of challenging binder-based vapors, and reliably hold a specific vacuum level to control the material's final properties.

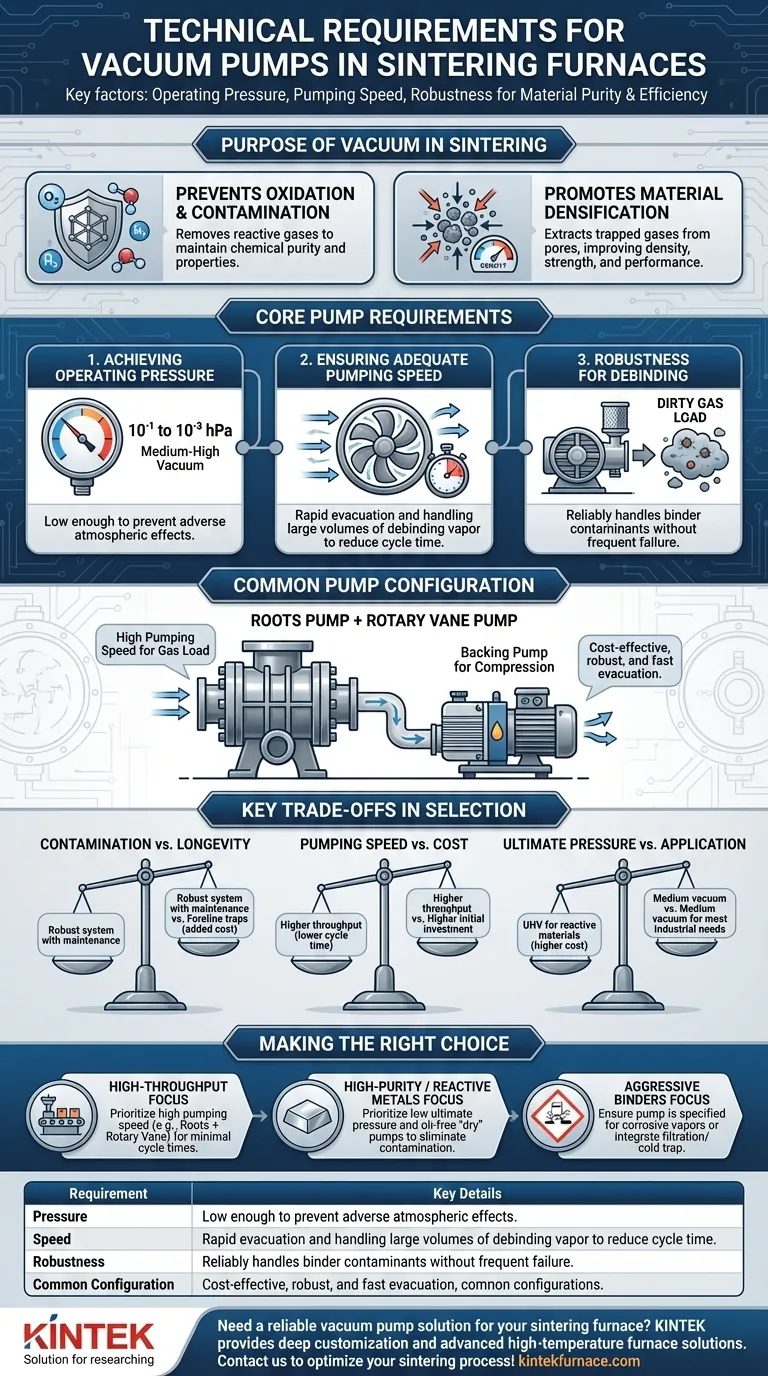

The Purpose of Vacuum in Sintering

Before detailing pump requirements, it's crucial to understand why a vacuum is used. The vacuum environment serves two primary goals in the sintering process.

Prevents Oxidation and Contamination

A vacuum removes reactive gases like oxygen and water vapor. This prevents the oxidation of sensitive materials such as active metals, refractory metals, and certain alloys, ensuring the final product maintains its chemical purity and intended properties.

Promotes Material Densification

The vacuum actively helps pull trapped gases and by-products out from between the material's particles. Removing these gases from the pores and defects allows the material to become more compact, significantly improving its final density, strength, and overall performance.

Core Pump Requirements Explained

The furnace's performance is directly tied to the capabilities of its vacuum system. The pump is not an accessory; it is a critical component that dictates process quality and efficiency.

1. Achieving the Necessary Operating Pressure

The ultimate pressure, or final vacuum level, is the most fundamental requirement. It must be low enough to prevent the adverse effects of atmospheric components on the material being processed.

For most powder metallurgy and hard metal sintering, this typically falls in the medium to high vacuum range, often between 10⁻¹ and 10⁻³ hPa. This level is sufficient to remove contaminants and facilitate densification.

2. Ensuring Adequate Pumping Speed

Pumping speed refers to the volume of gas the pump can remove per unit of time. High pumping speed is critical for two reasons.

First, it reduces the overall cycle time by enabling rapid evacuation of the furnace chamber. Second, and more importantly, it is required to handle the large volume of gas and vapor generated during the debinding stage, where binders are burned or evaporated off.

3. Robustness for the Debinding Process

The debinding stage is the harshest part of the cycle for the vacuum pump. Evaporated binder substances create a "dirty" gas load that can condense and contaminate or even seize a standard vacuum pump.

Therefore, the pump system must be robust—designed to reliably handle this vapor load without frequent failure or maintenance. This is often the most significant differentiator in pump selection.

Common Pump Configurations for Sintering

To meet these requirements, vacuum sintering furnaces rarely use a single pump. A multi-stage system is the standard approach.

The Workhorse: Rotary Vane and Roots Pump Combination

The most common configuration is a Roots pump (also called a Roots blower) backed by an oil-sealed rotary vane pump.

The Roots pump provides the extremely high pumping speed needed to handle the gas load during debinding. The rotary vane pump serves as the backing pump, compressing the gas to atmospheric pressure. This combination is cost-effective, robust, and capable of quickly reaching the required vacuum levels.

Understanding the Key Trade-offs

Selecting the right vacuum system involves balancing performance, cost, and maintenance.

Contamination vs. Pump Longevity

The primary challenge is managing the binder vapors. A robust system (like the Roots/vane combo) is designed for this, but these vapors can still contaminate pump oil and require regular maintenance. Foreline cold traps can be added to condense vapors before they reach the pump, but this adds complexity and cost.

Pumping Speed vs. Cost

A system with a higher pumping speed will reduce cycle times and increase throughput, but it also carries a higher initial investment. The pump size must be matched to the furnace volume and the expected gas load from the debinding process.

Ultimate Pressure vs. Application

While some applications in research or for highly reactive materials may require ultra-high vacuum (UHV), most industrial sintering does not. Over-specifying the ultimate pressure adds significant cost and complexity for no practical benefit. The key is to match the vacuum level to the material's specific needs.

Making the Right Choice for Your Process

Your choice of a vacuum system should be guided by your primary operational goal.

- If your primary focus is high-throughput production: Prioritize a system with high pumping speed, like a properly sized Roots and rotary vane combination, to minimize cycle times.

- If your primary focus is sintering high-purity or reactive metals: Prioritize a low ultimate pressure and consider oil-free "dry" pumps to eliminate any risk of hydrocarbon contamination from pump oil.

- If your primary focus is managing aggressive binders: Ensure the pump is specified for corrosive vapors or that you have integrated filtration or a cold trap to protect the system and reduce maintenance downtime.

Ultimately, the right vacuum system is one that reliably delivers the required process conditions with maximum uptime.

Summary Table:

| Requirement | Key Details |

|---|---|

| Operating Pressure | Must reach 10⁻¹ to 10⁻³ hPa for medium to high vacuum to prevent oxidation and aid densification. |

| Pumping Speed | High volume removal per time for rapid evacuation and handling debinding gas loads, reducing cycle times. |

| Robustness | Designed to withstand binder vapors and contaminants, ensuring reliability and minimizing maintenance. |

| Common Configuration | Roots pump backed by rotary vane pump for high speed and cost-effectiveness in handling vapor loads. |

Need a reliable vacuum pump solution for your sintering furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements, delivering robust pumps that handle contaminants, maintain material purity, and boost production efficiency. Contact us today to discuss how we can optimize your sintering process!

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance

- What is the mechanism of a vacuum sintering furnace for AlCoCrFeNi2.1 + Y2O3? Optimize Your High-Entropy Alloy Processing

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- What is the role of sintering or vacuum induction furnaces in battery regeneration? Optimize Cathode Recovery

- Why must sintering equipment maintain a high vacuum for high-entropy carbides? Ensure Phase Purity and Peak Density