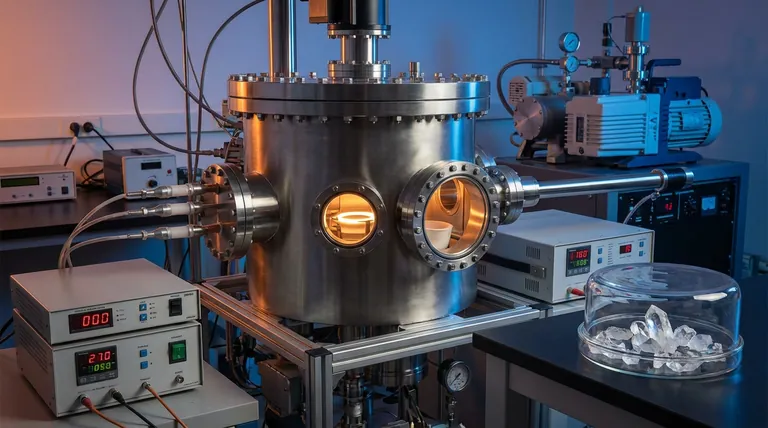

A high-vacuum pump system is essential for creating a chemically inert environment by lowering the pressure within the reaction vessel to approximately 30 mTorr (4 Pa). This deep evacuation eliminates residual oxygen and moisture, which is the defining factor in stabilizing rhenium in its required high oxidation state (Re VII) and preventing degradation during both synthesis and isolation.

Core Insight: The synthesis of calcium-based perrhenates is not merely about mixing ingredients; it is a battle against environmental contamination. The high-vacuum system acts as a critical process control that ensures single-phase purity by removing the atmosphere that triggers unwanted side reactions and hydration.

Protecting Chemical Integrity During Reaction

The primary function of the high-vacuum system is to prepare the reaction vessel for high-temperature processing. Without this step, the specific chemistry required for perrhenates cannot occur reliably.

Eliminating Atmospheric Contaminants

The system evacuates the chamber to 30 mTorr (4 Pa).

This extreme reduction in pressure removes virtually all traces of oxygen and moisture, which are the primary sources of contamination in sensitive synthesis reactions.

Stabilizing Oxidation States

Calcium-based perrhenates require rhenium to maintain a high oxidation state (Re VII).

The presence of oxygen or moisture can alter this state. By maintaining a vacuum, the system locks in the chemical environment necessary to preserve this specific electronic configuration.

Optimizing the Annealing Phase

Once the environment is secured, the synthesis moves to the annealing phase, where temperatures range from 560 to 750 °C.

Preventing Side Reactions

At these elevated temperatures, reactants become highly volatile and reactive.

The vacuum environment prevents the reactants from engaging in undesirable side reactions with atmospheric gases, ensuring the reaction pathway remains focused on the target compound.

Ensuring Single-Phase Purity

By eliminating competing reactions, the vacuum allows for the formation of high-quality single-phase crystals.

This leads to a uniform product free from impurities that would otherwise compromise the material's properties.

Preserving Quality During Isolation

While the primary reference focuses on the reaction vessel, vacuum systems play a secondary, critical role during the filtration and isolation of the crystals.

Accelerating Separation

Vacuum filtration applies strong negative pressure to drive the rapid separation of crystals from the mother liquor.

This speed is essential for process efficiency and yield maximization.

Managing Hygroscopic Sensitivity

Calcium-based perrhenate crystals are often hygroscopic, meaning they readily absorb water from the air.

Rapid vacuum filtration minimizes the time the crystals are exposed to humid environments, ensuring they maintain clean surfaces and stable physicochemical properties.

Common Pitfalls to Avoid

Understanding the limitations of your vacuum system is as important as understanding its benefits.

Inadequate Pressure Levels

Simply "applying vacuum" is insufficient; the specific target of 30 mTorr must be reached.

Failure to achieve this depth of vacuum will leave enough residual oxygen to oxidize the reactants or alter the final crystal phase.

Moisture Re-introduction

A high-quality synthesis can be ruined during the isolation phase if the filtration vacuum is weak.

Slow filtration allows moisture to re-enter the crystal structure, negating the purity achieved during the high-temperature annealing.

Making the Right Choice for Your Goal

To ensure the successful synthesis of calcium-based perrhenates, you must apply vacuum technology strategically across the entire workflow.

- If your primary focus is Phase Purity: rigorous evacuation to 30 mTorr (4 Pa) prior to annealing is non-negotiable to protect the Re(VII) oxidation state.

- If your primary focus is Crystal Stability: Ensure your filtration system uses strong negative pressure to minimize atmospheric exposure time for hygroscopic products.

Control the atmosphere, and you control the quality of the crystal.

Summary Table:

| Process Phase | Critical Vacuum Level | Primary Benefit |

|---|---|---|

| Pre-Reaction | 30 mTorr (4 Pa) | Removes O2 and moisture to prevent contamination |

| Annealing (560-750°C) | High Vacuum | Stabilizes Re(VII) state and ensures single-phase purity |

| Isolation/Filtration | Strong Negative Pressure | Accelerates separation and protects hygroscopic crystals |

Elevate Your Material Synthesis Precision

Achieving single-phase purity in sensitive chemical reactions requires more than just standard equipment—it requires precise environmental control. KINTEK provides industry-leading laboratory solutions backed by expert R&D and manufacturing.

Whether you are synthesizing advanced perrhenates or conducting complex thermal processing, our range of Muffle, Tube, Rotary, Vacuum, and CVD systems are fully customizable to meet your unique research needs. Ensure chemical integrity and repeatable results with KINTEK’s high-temperature technology.

Ready to optimize your lab's vacuum and thermal capabilities?

Contact our specialists today to find your custom solution.

References

- New calcium perrhenates: synthesis and crystal structures of Ca(ReO<sub>4</sub>)<sub>2</sub> and K<sub>2</sub>Ca<sub>3</sub>(ReO<sub>4</sub>)<sub>8</sub>·4H<sub>2</sub>O. DOI: 10.1515/zkri-2025-0008

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- Ultra High Vacuum Observation Window Stainless Steel Flange Sapphire Glass Sight Glass for KF

- Ultra High Vacuum Observation Window KF Flange 304 Stainless Steel High Borosilicate Glass Sight Glass

People Also Ask

- What is the function of a high-temperature annealing furnace for gold paste electrodes? Optimize Sensor Conductivity

- Why is a vacuum drying oven preferred for BC-CFO composite powders? Preserving Magnetic and Structural Integrity

- What is vacuum sintering and where is it commonly used? Discover High-Purity Material Processing

- How does a vacuum heating system contribute to the resin modification? Enhance Density & Chemical Purity

- How does the heating process work in a hot wall vacuum furnace? Discover Its Indirect Heating Benefits

- How does a vacuum furnace prevent oxidation of the workpiece? Achieve Purity and Precision in High-Temp Processing

- What is the role of a vacuum oven or vacuum furnace in the preparation of ordered porous magnesium oxide via the nanocasting method? Ensure High-Fidelity Material Replication

- What types of heat treatment processes are performed in vacuum furnaces? Achieve Superior Metallurgical Control and Quality