The primary function of a high-temperature annealing furnace in this context is to transform raw gold paste into a solid, highly conductive electrode film through precise thermal processing. By reaching temperatures of approximately 900°C, the furnace removes organic impurities and fuses gold particles together. This ensures the electrode adheres permanently to the ceramic substrate, establishing the foundation for reliable sensor performance.

The annealing process is a critical phase transformation where loose gold particles sinter into a continuous metallic layer, simultaneously removing organic binders and structurally bonding the electrode to its base for maximum durability.

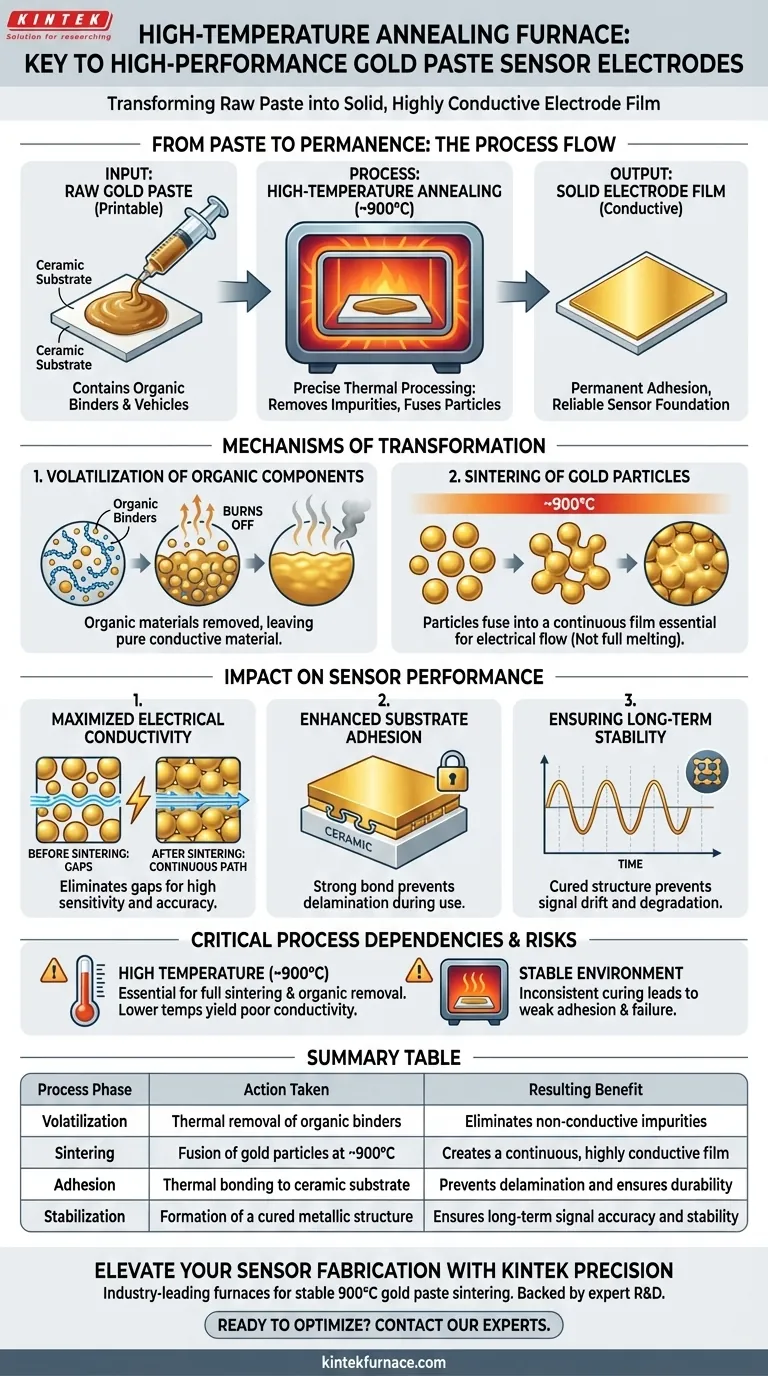

The Mechanisms of Transformation

The furnace does not simply dry the paste; it fundamentally alters the material's chemical and physical structure through two specific mechanisms.

Volatilization of Organic Components

Gold paste contains organic binders and vehicles to make it printable. These components are non-conductive and must be removed.

The high heat of the furnace causes these organic materials to volatilize. They are burned off completely, leaving behind only the pure conductive material necessary for the electrode's function.

The Sintering of Gold Particles

Once the organics are removed, the remaining gold particles are subjected to intense heat (approx. 900°C).

At this temperature, the particles undergo sintering. They fuse together without fully melting, merging into a continuous, cohesive film. This transition from individual particles to a solid film is essential for electrical flow.

Impact on Sensor Performance

The physical changes induced by the annealing furnace directly translate to the operational quality of the final sensor.

Maximizing Electrical Conductivity

The sintering process creates a continuous path for electrons.

By eliminating the gaps between individual gold particles, the furnace ensures the resulting film is highly conductive. This is vital for the sensor's sensitivity and accuracy.

Enhancing Substrate Adhesion

The furnace facilitates a strong bond between the gold electrode and the ceramic substrate.

Without this high-temperature treatment, the gold layer would merely sit on top of the ceramic. The heat ensures they adhere firmly, preventing delamination during use.

Ensuring Long-Term Stability

A sensor must provide consistent readings over time.

The solidified, cured structure created by the furnace ensures signal acquisition remains stable. This prevents signal drift or failure caused by physical degradation of the electrode.

Understanding Process Dependencies

While the furnace enables high performance, the process relies heavily on maintaining specific environmental parameters.

The Necessity of High Temperature

The process explicitly requires temperatures reaching approximately 900°C.

Lower temperatures would likely fail to fully sinter the gold or burn off all organics. This would result in a "muddy" electrode with poor conductivity and weak structural integrity.

The Risk of Incomplete Curing

If the stable environment of the furnace is compromised, the curing process becomes inconsistent.

Incomplete curing leads to weak adhesion between the gold and the ceramic. This creates a point of failure where the electrode could detach or crack under stress.

Making the Right Choice for Your Goal

When evaluating the annealing process for sensor fabrication, focus on the specific outcome required for your application.

- If your primary focus is Signal Integrity: Prioritize the completeness of the sintering phase to eliminate particle gaps and maximize conductivity.

- If your primary focus is Mechanical Durability: Ensure the furnace maintains a stable 900°C environment to guarantee the strongest possible adhesion to the ceramic substrate.

The annealing furnace is the defining tool that converts a temporary paste application into a permanent, high-performance sensing component.

Summary Table:

| Process Phase | Action Taken | Resulting Benefit |

|---|---|---|

| Volatilization | Thermal removal of organic binders | Eliminates non-conductive impurities |

| Sintering | Fusion of gold particles at ~900°C | Creates a continuous, highly conductive film |

| Adhesion | Thermal bonding to ceramic substrate | Prevents delamination and ensures durability |

| Stabilization | Formation of a cured metallic structure | Ensures long-term signal accuracy and stability |

Elevate Your Sensor Fabrication with KINTEK Precision

High-performance sensor electrodes require uncompromising thermal accuracy. KINTEK provides industry-leading muffle, tube, and vacuum furnaces engineered to maintain the stable 900°C environment essential for perfect gold paste sintering.

Backed by expert R&D and world-class manufacturing, our systems ensure maximum conductivity and superior substrate adhesion for your unique research or production needs.

Ready to optimize your annealing process? Contact our technical experts today to find the customizable high-temperature solution that fits your lab.

Visual Guide

References

- Sovandeb Sen, Susmita Kundu. Bio-waste derived reduced graphene oxide (rGO) decorated Cr (III) doped α-Fe2O3 nanocomposite for selective ppm-level acetone sensing at room temperature: Potential approach towards non-invasive diagnosis of diabetic biomarker. DOI: 10.1007/s42114-025-01241-0

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- How does a diffusion annealing furnace enhance magnet coercivity? Boost Performance with Grain Boundary Diffusion

- How does vacuum level affect the annealing process? Optimize Material Purity and Performance

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- Why is a vacuum oven necessary for treating precursors? Optimize Nitrogen & Sulfur Co-Doped Carbon Synthesis

- What safety measures are important for vacuum annealing furnaces? Ensure Reliable Operation and Protect Your Lab

- How a High-Vacuum Brazing Furnace Enhances CuMnNi Thin Film Piezoresistivity through Precision Annealing

- What role does a high-temperature vacuum furnace play in sintering magnesium composites? Key Success Factors