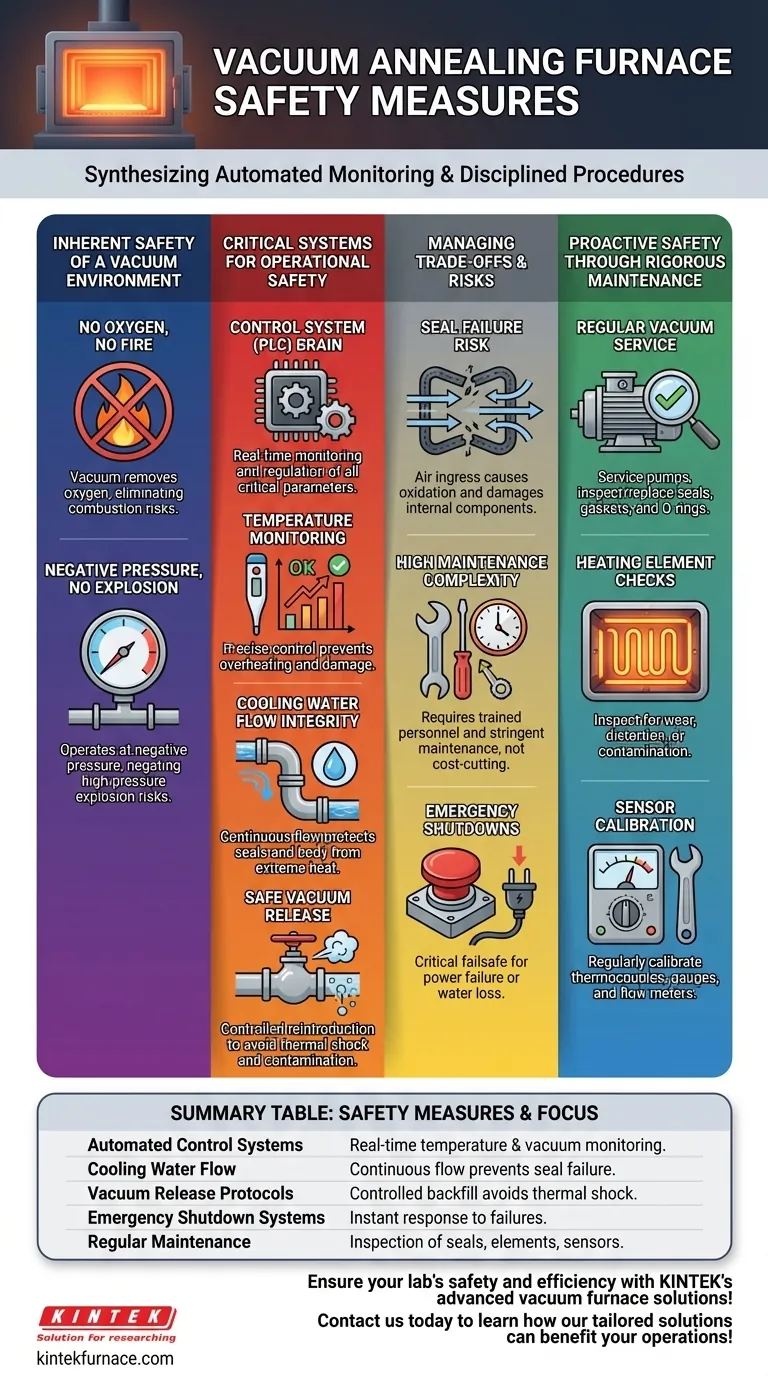

At its core, safety in a vacuum annealing furnace relies on a synthesis of automated monitoring systems and disciplined operational procedures. The most critical measures involve real-time monitoring of temperature and cooling water flow, ensuring proper vacuum release protocols, having a reliable emergency shutdown system, and conducting regular inspections of all critical components like seals and heating elements.

While vacuum furnaces inherently eliminate traditional risks like fire and explosion by removing oxygen and operating at negative pressure, their safety hinges on maintaining the integrity of that controlled environment. True safety is achieved not by just preventing old hazards, but by actively managing the unique conditions of high heat and deep vacuum.

The Inherent Safety of a Vacuum Environment

A primary reason for using a vacuum furnace is its intrinsic safety profile, which fundamentally differs from conventional atmospheric or pressure-based heating systems.

No Oxygen, No Fire

By operating in a vacuum, the furnace removes the oxygen required for combustion. This virtually eliminates the risk of fire from the oxidation of workpieces or other materials inside the furnace, a significant hazard in traditional high-temperature processes.

Negative Pressure, No Explosion

Unlike pressure vessels or boilers that operate at high positive pressures, vacuum furnaces operate at negative pressure. This design negates the risk of a high-pressure explosion, making the system fundamentally safer from a mechanical standpoint.

Critical Systems for Operational Safety

While the vacuum provides a safe baseline, active systems are essential for managing the process and responding to potential failures.

The Central Role of the Control System

Modern furnaces utilize a Programmable Logic Controller (PLC) and programmable temperature controllers as the brain of the operation. These systems provide real-time monitoring and regulation of all critical parameters, from temperature to vacuum levels, ensuring the process runs within safe, predefined limits.

Temperature Monitoring and Regulation

Precise temperature control is paramount. Advanced systems detect and respond to any anomalies instantly, preventing overheating that could damage the workpiece, compromise the furnace's structural integrity, or lead to unsafe conditions.

Cooling Water Flow Integrity

The furnace's body, seals, and other components are protected from extreme heat by a cooling water system. A continuous and adequate flow is non-negotiable. Any interruption can cause seals to fail or the vessel to warp, leading to a loss of vacuum and potentially catastrophic equipment damage.

Safe Vacuum Release Procedures

Reintroducing atmosphere into the chamber must be done in a controlled manner. Releasing the vacuum too quickly or with an improper backfill gas can cause thermal shock to the heated parts or introduce contaminants, compromising both the product and operator safety.

Understanding the Trade-offs and Risks

Objectivity requires acknowledging that while a vacuum environment solves some problems, it introduces new complexities that must be managed.

The Hidden Risk of Seal Failure

The entire system's integrity depends on its vacuum seals and gaskets. Should a seal fail at high temperature, air will rush into the chamber. This can cause immediate, aggressive oxidation of the hot workpiece, potentially ruining the product and damaging internal furnace components like heating elements.

High Cost and Maintenance Complexity

Vacuum furnaces are sophisticated and expensive. Their complexity demands a higher level of maintenance performed by well-trained personnel. The stringent requirements for vacuum integrity mean that cutting corners on service is not a cost-saving measure but a direct safety liability.

The Importance of Emergency Shutdowns

Emergency shutdown systems are not just a regulatory requirement; they are a critical failsafe. These systems are designed to react instantly to dangerous conditions like a loss of cooling water or a major power failure, safely shutting down the heating and vacuum systems to prevent damage.

Proactive Safety Through Rigorous Maintenance

A reliable safety protocol is proactive, not reactive. It is built on a foundation of consistent and thorough preventative maintenance.

Regular Vacuum System Service

This includes servicing the vacuum pumps that create the environment and regularly inspecting and replacing all door seals, gaskets, and O-rings to prevent leaks.

Heating Element and Furnace Interior Checks

Heating elements degrade over time. Regular inspection for wear, distortion, or contamination ensures reliable heating and prevents unexpected failures during a cycle.

Control System and Sensor Calibration

The control system is only as good as the data it receives. Regular calibration of thermocouples, vacuum gauges, and flow meters is essential to ensure the furnace's "brain" is making decisions based on accurate information.

Implementing a Robust Safety Protocol

To ensure safety, you must align your procedures with your primary operational goals.

- If your primary focus is operational reliability: Prioritize the integrity of your real-time control systems, ensuring all sensors are calibrated and automated alerts are functioning correctly.

- If your primary focus is long-term asset protection: Implement and strictly adhere to a rigorous preventative maintenance schedule, especially for the cooling system and vacuum seals.

- If your primary focus is operator safety: Enforce comprehensive training on standard operating procedures, with a specific emphasis on safe vacuum release and the correct response during an emergency shutdown.

Ultimately, safety in a vacuum furnace is the direct result of understanding it as a complete system, where each component's integrity is critical to the whole.

Summary Table:

| Safety Measure | Key Focus |

|---|---|

| Automated Control Systems | Real-time monitoring of temperature and vacuum levels |

| Cooling Water Flow | Continuous flow to prevent seal failure and overheating |

| Vacuum Release Protocols | Controlled backfill to avoid thermal shock and contamination |

| Emergency Shutdown Systems | Instant response to failures like power loss or water interruption |

| Regular Maintenance | Inspection of seals, heating elements, and sensor calibration |

Ensure your lab's safety and efficiency with KINTEK's advanced vacuum furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace options like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability allows us to precisely meet your unique experimental needs, enhancing reliability and protecting your assets. Contact us today to learn how our tailored solutions can benefit your operations!

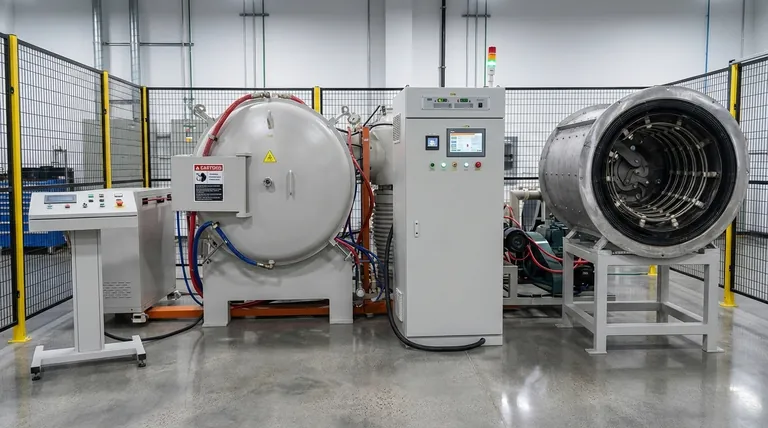

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- Why is a high vacuum essential for Ti-6Al-4V sintering? Protect Your Alloys from Embrittlement

- What tasks does a high-temperature vacuum sintering furnace perform for PEM magnets? Achieve Peak Density

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control