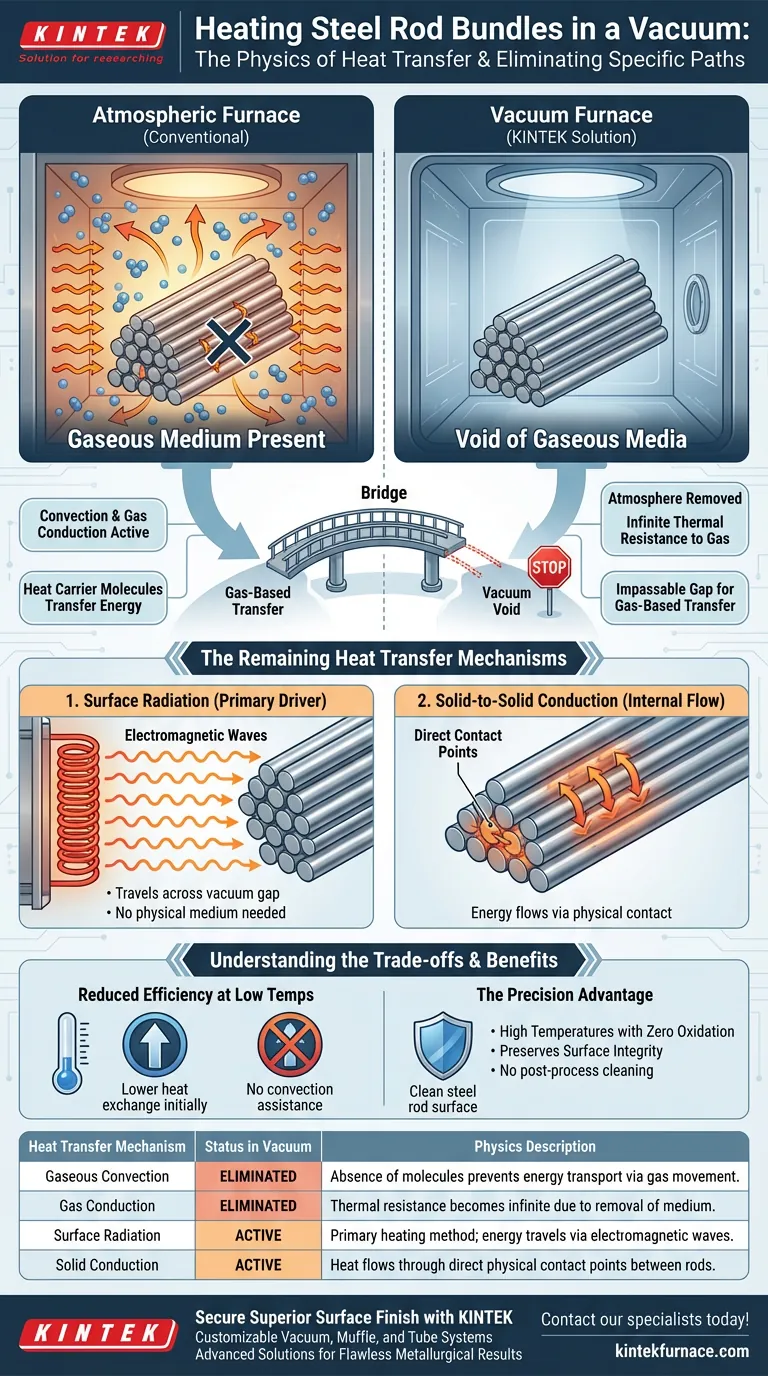

Heating steel rod bundles in a vacuum creates an environment intentionally void of gaseous media. By removing the atmosphere, you effectively make the thermal resistance of gas infinite, which physically eliminates any heat transfer mechanism that relies on air or gas molecules to carry energy.

In a vacuum furnace, the removal of air creates a barrier to gas-based heat transfer. This restricts the heating process exclusively to surface radiation and solid-to-solid conduction, accepting lower thermal efficiency at low temperatures in exchange for completely preventing surface oxidation.

The Physics of Vacuum Heating

Eliminating the Medium

In conventional atmospheric furnaces, heat moves largely through the air or gas surrounding the steel. The gas molecules absorb energy and transfer it to the steel rods.

In a vacuum, this gaseous medium is removed. Without molecules to act as carriers, the mechanisms of convection and gas conduction simply cannot occur.

Infinite Thermal Resistance

The primary reference notes that removing the gas causes the gas conduction thermal resistance to become effectively infinite.

Think of this like a bridge being removed. Heat energy that would normally travel through the gas now faces an impassable gap, forcing it to find alternative routes.

The Remaining Heat Transfer Mechanisms

Surface Radiation

With the gas removed, radiation becomes a primary driver of heat transfer.

Heat energy travels as electromagnetic waves across the vacuum gap between the heating elements and the rod bundle surface. This mechanism does not require a physical medium to operate.

Solid-to-Solid Conduction

Within the rod bundle itself, heat moves through direct physical contact.

Energy flows from the outer rods to the inner rods strictly through the points where the steel surfaces touch. This is known as solid-to-solid contact conduction.

Understanding the Trade-offs

Reduced Efficiency at Low Temperatures

Eliminating gas-based transfer comes at a cost. At lower temperatures, radiation is less effective, and there is no convection to assist the process.

This results in lower heat exchange efficiency during the initial heating phases compared to atmospheric furnaces, which utilize the air to help distribute heat.

The Precision Advantage

Despite the reduced efficiency, this method is preferred for precision steel components.

The complete lack of oxygen means you can achieve high temperatures while completely preventing surface oxidation. This preserves the surface integrity of the steel rods without requiring post-process cleaning.

Making the Right Choice for Your Goal

When deciding between vacuum heat treatment and atmospheric methods, consider your specific priorities:

- If your primary focus is Surface Integrity: Choose vacuum heat treatment to ensure zero oxidation on precision components, regardless of heating speed.

- If your primary focus is Heating Speed: Be aware that vacuum heating offers lower efficiency at lower temperatures due to the lack of convective heat transfer.

By understanding how the vacuum alters the thermal landscape, you can optimize your process for quality rather than just speed.

Summary Table:

| Heat Transfer Mechanism | Status in Vacuum | Physics Description |

|---|---|---|

| Gaseous Convection | Eliminated | Absence of molecules prevents energy transport via gas movement. |

| Gas Conduction | Eliminated | Thermal resistance becomes infinite due to the removal of the medium. |

| Surface Radiation | Active | Primary heating method; energy travels via electromagnetic waves. |

| Solid Conduction | Active | Heat flows through direct physical contact points between rods. |

Secure Superior Surface Finish with KINTEK

Don't compromise the integrity of your precision steel components with surface oxidation. Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum, Muffle, and Tube systems—all customizable for your unique lab or industrial requirements. Our advanced vacuum heat treatment solutions help you navigate the trade-offs of thermal efficiency to achieve flawless metallurgical results.

Contact our specialists today to find the perfect furnace for your application!

Visual Guide

References

- Rafał Wyczółkowski, M. Gała. Computational Model of the Effective Thermal Conductivity of a Bundle of Round Steel Bars. DOI: 10.3390/ma18020373

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- What is the primary function of a vacuum high-temperature furnace in the synthesis of Mg3Sb2 thermoelectric materials?

- What factors should be considered when choosing a vacuum furnace? Optimize Your Material Processing with Expert Tips

- What is the purpose of performing medium vacuum annealing on working ampoules? Ensure Pure High-Temp Diffusion

- What is the working principle of a vacuum heat treatment furnace? Achieve Clean, High-Integrity Metal Parts

- What are the advantages of using semi-coke powder in vacuum reduction for zinc extraction? Boost Diffusion Rates

- Why is a non-consumable vacuum arc furnace typically selected for preparing AlFeCoCrNiCu high-entropy alloy substrates?

- How does the sintering process work? Master the Art of Powder-to-Solid Transformation

- Why does magnesium distillation use a two-stage pump? A strategic division of labor for efficiency.