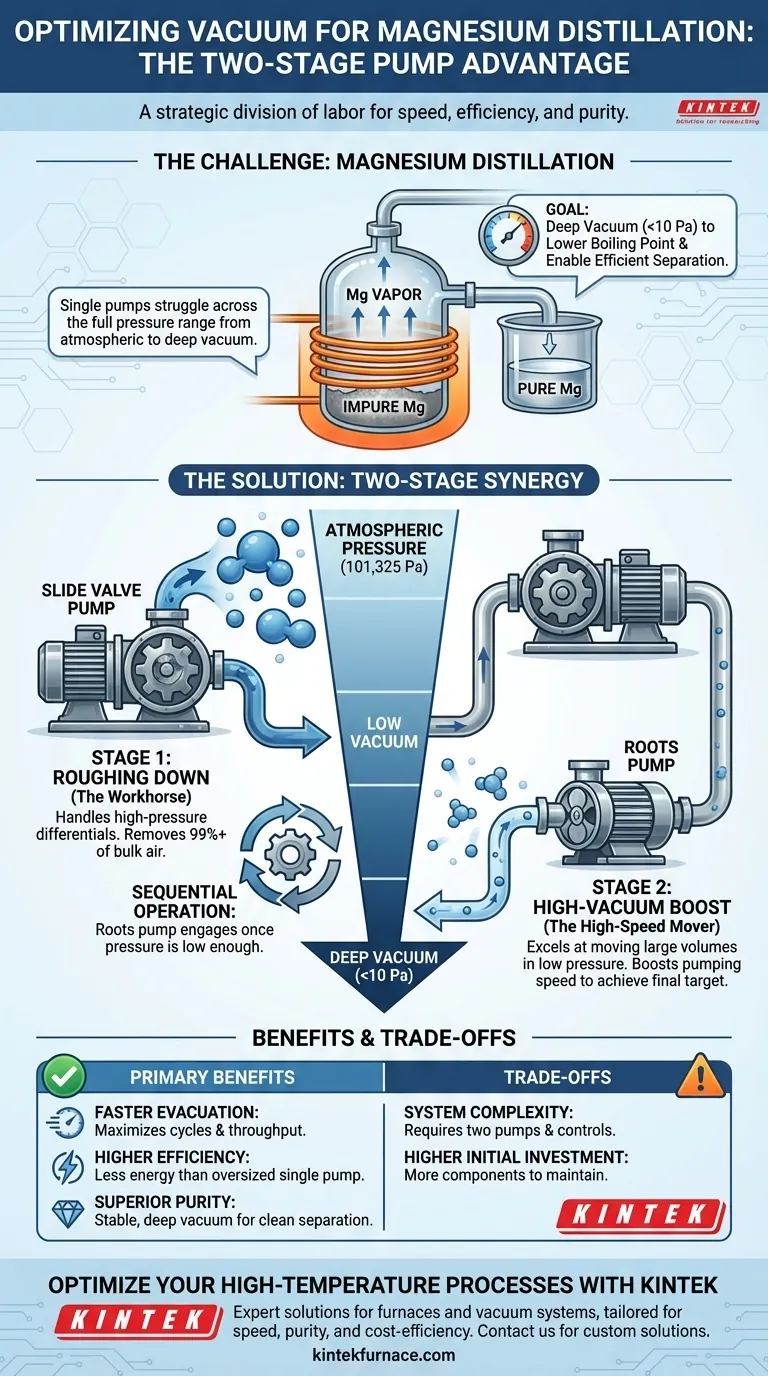

In short, this two-stage pump configuration is a strategic division of labor. The system uses a robust slide valve pump to handle the initial, high-effort work of removing the bulk of air from the system, and then engages a high-speed Roots pump to efficiently achieve the final, deep vacuum required for magnesium distillation. This combination is far more effective and energy-efficient than any single pump could be for this demanding task.

A vacuum system is not about a single pump's power, but about matching the right pump to the right pressure range. The slide valve pump overcomes atmospheric pressure, while the Roots pump excels at moving large gas volumes in an already-evacuated environment.

The Critical Role of Vacuum in Magnesium Distillation

To understand the pump configuration, we must first understand the process it serves. Magnesium distillation is a purification process that relies on a fundamental principle of physics.

Lowering the Boiling Point

Magnesium, like all elements, has a boiling point—the temperature at which it turns into a vapor. Under normal atmospheric pressure, this temperature is extremely high.

By drastically reducing the pressure inside the distillation chamber, we can lower magnesium's boiling point to a much more manageable temperature.

Enabling Efficient Separation

This low-temperature vaporization is the key to purification. The process heats the impure magnesium just enough for it to turn into a gas, leaving heavier, less volatile impurities behind as solids or liquids. The pure magnesium vapor is then collected and condensed elsewhere.

Why a Single Pump Is Inefficient

Achieving the required vacuum level (typically below 10 Pascals) presents a significant engineering challenge. No single pump type is optimized to work efficiently across the entire pressure range from atmospheric pressure (101,325 Pa) down to 10 Pa.

The Backing Pump: The "Workhorse"

The slide valve pump is a type of oil-sealed rotary pump. It is designed to work against high-pressure differentials, making it excellent for the initial "roughing" stage.

Its job is to take the system from atmospheric pressure and pump out the vast majority of air molecules. However, its pumping speed drops significantly as the vacuum level gets deeper.

The Booster Pump: The "High-Speed Mover"

The Roots pump is a booster pump. It works by rapidly moving large volumes of gas from its inlet to its outlet, but it cannot exhaust directly to the atmosphere.

It requires a "backed" or low-pressure environment at its outlet to function. It excels where the slide valve pump falters: moving massive volumes of the few remaining gas molecules in a near-vacuum environment.

How the Two Pumps Work in Synergy

The two-stage system coordinates the strengths of each pump in a highly effective sequence.

Stage 1: The Roughing Down Phase

First, only the slide valve pump operates. It acts as the backing pump, doing the heavy lifting of removing over 99% of the air from the chamber and creating a preliminary low-vacuum environment.

Stage 2: The High-Vacuum Phase

Once the pressure is low enough for the Roots pump to operate efficiently, it is switched on. The Roots pump rapidly pulls gas from the chamber and feeds it into the inlet of the still-running slide valve pump.

The Roots pump acts as a booster, dramatically increasing the system's pumping speed at low pressures and quickly pulling the chamber down to the target operational vacuum.

Understanding the Trade-offs

While highly effective, this configuration is a deliberate engineering choice with clear benefits and complexities.

The Primary Benefit: Speed and Efficiency

This combined approach evacuates the system far more quickly and with less energy consumption than using a single, oversized pump designed to handle the entire pressure range.

The Downside: System Complexity

The main trade-off is increased complexity. The system requires two pumps, more piping, and a control system to manage their sequential operation. This means a higher initial investment and more components to maintain over time.

Making the Right Choice for Your Process

The necessity of this configuration becomes clear when viewed through the lens of industrial process goals.

- If your primary focus is process speed: The rapid pump-down time achieved by the Roots booster is essential for maximizing cycles and overall plant throughput.

- If your primary focus is product purity: Achieving and maintaining a deep, stable vacuum is non-negotiable for ensuring clean vaporization and effective separation from impurities.

- If your primary focus is operational cost: The long-term energy efficiency of this specialized, two-stage system outweighs the higher initial capital and maintenance complexity.

Ultimately, combining a slide valve pump with a Roots pump is the standard for a reason: it is the most effective and reliable method for creating the demanding vacuum conditions essential for high-purity magnesium production.

Summary Table:

| Pump Stage | Pump Type | Primary Function | Pressure Range |

|---|---|---|---|

| Stage 1: Backing | Slide Valve Pump | Handles high-pressure differentials; removes bulk of air (roughing) | Atmospheric to low vacuum |

| Stage 2: Boosting | Roots Pump | Moves large gas volumes rapidly in a near-vacuum; achieves deep vacuum | Low to high vacuum (< 10 Pa) |

Optimize Your High-Temperature Vacuum Processes with KINTEK

Just as the right pump configuration is critical for magnesium distillation, having the right high-temperature furnace is essential for your lab's success. Whether your process requires precise temperature control under vacuum or an inert atmosphere, KINTEK's expertise ensures optimal performance.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD furnace systems, all customizable for your unique needs. Our solutions are designed to enhance process speed, product purity, and operational cost-efficiency for industries like metals processing, ceramics, and advanced materials research.

Ready to achieve superior results? Contact our experts today to discuss how a KINTEK furnace system can be tailored to your specific application.

Visual Guide

Related Products

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- Why is a high vacuum pumping system necessary for carbon nanotube peapods? Achieve Precise Molecular Encapsulation

- Why is it necessary to achieve a vacuum level of 3 x 10^-2 mm Hg for quartz tube sealing? Ensure Safety and Purity

- Why is a high vacuum system critical for sealing the quartz tube used in Fe3GeTe2 single crystal preparation?

- What role do the exhaust branch pipes at the top of a vacuum chamber play? Optimize Your Pressure Control Today

- Why is it necessary to maintain a pressure below 6.7 Pa during stainless steel refining? Achieve Ultra-High Purity