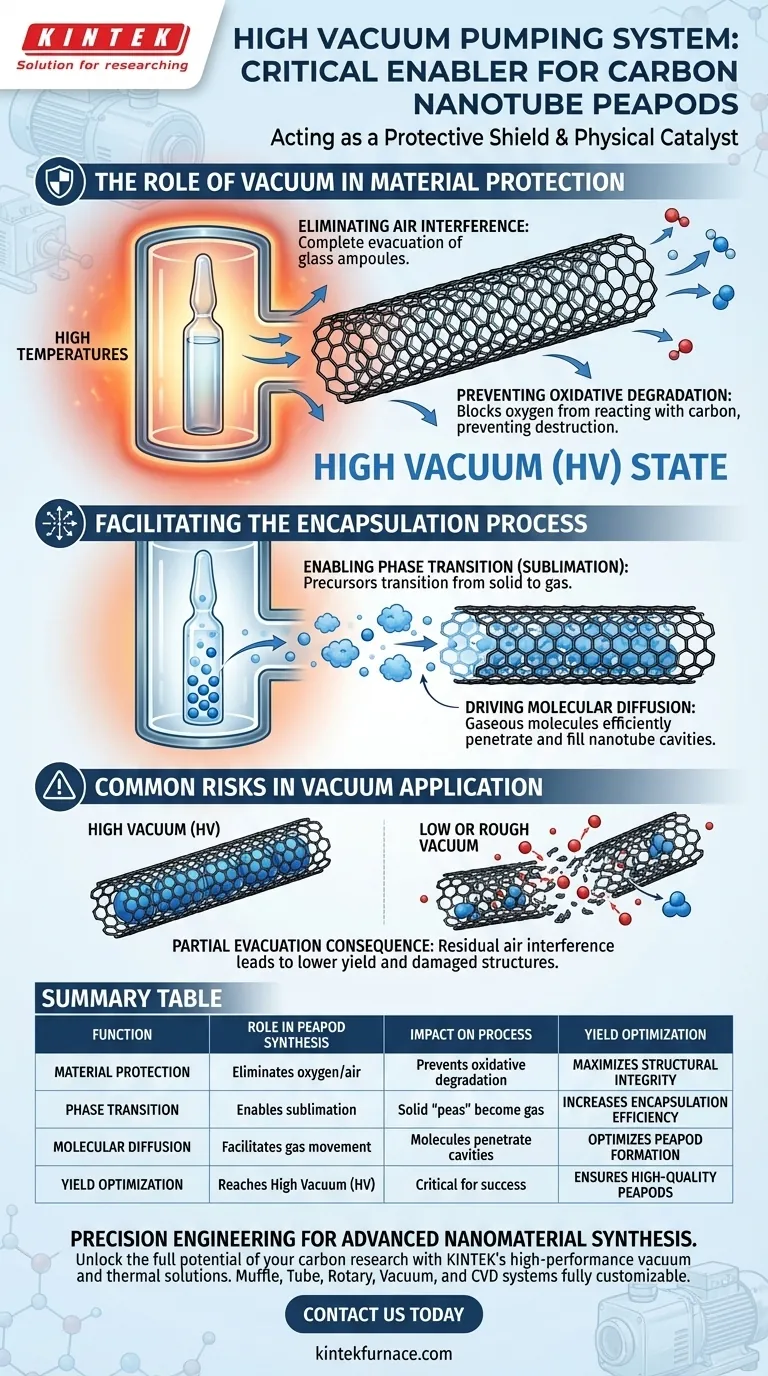

A high vacuum pumping system is the critical enabler for preparing carbon nanotube peapod structures, acting as both a protective shield and a physical catalyst. By evacuating the glass ampoules used in the process to a High Vacuum (HV) state, the system prevents the carbon structures from burning up while simultaneously forcing the precursor molecules to turn into gas and fill the nanotubes.

The high vacuum environment creates a necessary dual-purpose condition: it safeguards carbon materials against heat-induced oxidative degradation while simultaneously driving the sublimation and diffusion required to encapsulate molecules inside the nanotubes.

The Role of Vacuum in Material Protection

The synthesis of carbon nanotube peapods requires high temperatures. To ensure the materials survive this environment, the atmosphere within the reaction vessel must be strictly controlled.

Eliminating Air Interference

The primary function of the high vacuum system is to completely evacuate the glass ampoules containing the reactants.

This removal of air is not merely for purity; it is a structural necessity for the carbon nanotubes.

Preventing Oxidative Degradation

Carbon materials are highly susceptible to damage when exposed to oxygen at high temperatures.

Without a high vacuum, the heat required for synthesis would cause the carbon nanotubes to react with oxygen.

This would lead to oxidative degradation, effectively destroying the nanotube structure before the "peapods" can be formed.

Facilitating the Encapsulation Process

Beyond protection, the vacuum actively changes the physical behavior of the precursor molecules (the "peas").

Enabling Phase Transition (Sublimation)

For the precursor molecules to enter the nanotubes, they must move freely.

The high vacuum environment provides the physical conditions necessary for these precursors to sublime—transitioning directly from a solid to a gas phase.

This gaseous state is essential for the mobility of the molecules within the ampoule.

Driving Molecular Diffusion

Once the precursors are in a gas phase, they must navigate into the tiny space inside the nanotubes.

The vacuum environment facilitates this diffusion process.

It allows the gaseous molecules to penetrate the nanotube cavities efficiently, completing the formation of the peapod structure.

Common Risks in Vacuum Application

While the necessity of the system is clear, understanding the risks of improper application is equally important.

The Consequence of Partial Evacuation

Ideally, the system must reach a High Vacuum (HV) state.

If the system only achieves a low or rough vacuum, residual air interference will persist.

This partial evacuation often results in a lower yield of peapods and damaged carbon structures due to incomplete protection against oxidation.

Making the Right Choice for Your Goal

To ensure the successful synthesis of carbon nanotube peapods, your vacuum strategy must prioritize both protection and physics.

- If your primary focus is Structural Integrity: Ensure your pumping system can reach and maintain a High Vacuum (HV) to completely eliminate oxygen and prevent carbon degradation.

- If your primary focus is Encapsulation Efficiency: Rely on the vacuum to lower the sublimation point of your precursors, ensuring they vaporize and diffuse fully into the cavities.

A high vacuum system is not just an accessory; it is the fundamental control mechanism that allows high-temperature synthesis to occur without destroying the very materials you are trying to create.

Summary Table:

| Function | Role in Peapod Synthesis | Impact on Process |

|---|---|---|

| Material Protection | Eliminates oxygen/air interference | Prevents oxidative degradation of carbon structures |

| Phase Transition | Enables sublimation of precursors | Converts solid "peas" into mobile gaseous molecules |

| Molecular Diffusion | Facilitates gas movement | Ensures molecules penetrate and fill nanotube cavities |

| Yield Optimization | Reaches High Vacuum (HV) state | Maximizes structural integrity and encapsulation efficiency |

Precision Engineering for Advanced Nanomaterial Synthesis

Unlock the full potential of your carbon research with KINTEK’s high-performance vacuum and thermal solutions. Backed by expert R&D and manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet the rigorous demands of carbon nanotube peapod production.

Whether you need to maintain a strict High Vacuum (HV) environment to prevent oxidation or require precise thermal control for precursor sublimation, KINTEK provides the reliability your lab deserves. Contact us today to find the perfect system for your unique needs.

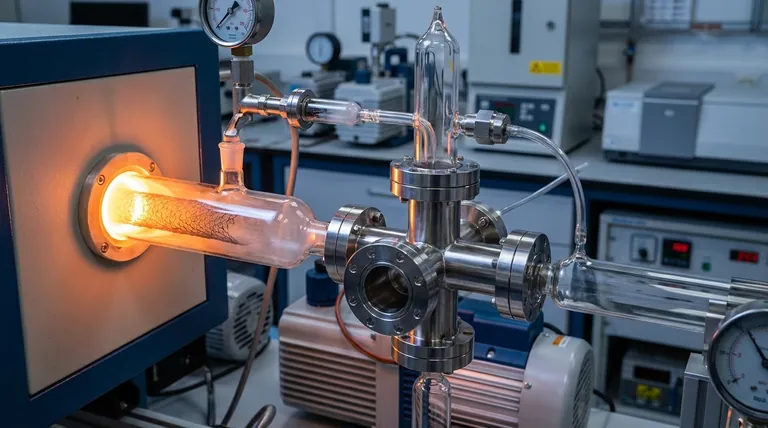

Visual Guide

References

- Clara Freytag, Thomas Pichler. Systematic Optimization of the Synthesis of Confined Carbyne. DOI: 10.1002/smtd.202500075

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Ultra High Vacuum Stainless Steel KF ISO CF Flange Pipe Straight Pipe Tee Cross Fitting

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- How do vacuum filtration systems operate in industrial sludge dehydration? Achieve Efficient Liquid-Solid Separation

- Why is a corundum crucible required for the sintering of manganese ore at 1200 °C? Ensure High-Purity Results

- What material are quartz tubes made from and what temperature can they withstand? Discover High-Temp Solutions for Your Lab

- Why are quartz tubes indispensable in advanced technologies? Unlock Purity and Performance

- What are the primary functions of a Quartz Flow Reactor? Enhance Precision in Oxidation Research

- What other industrial applications do graphite crucible furnaces have beyond metal melting? Unlock Advanced Material Processing

- What are the requirements for high-temperature heating equipment and quartz crucibles in incineration ash pretreatment?

- Why is an alumina crucible used for vacuum carbothermal reduction? Ensure Purity at 1723 K