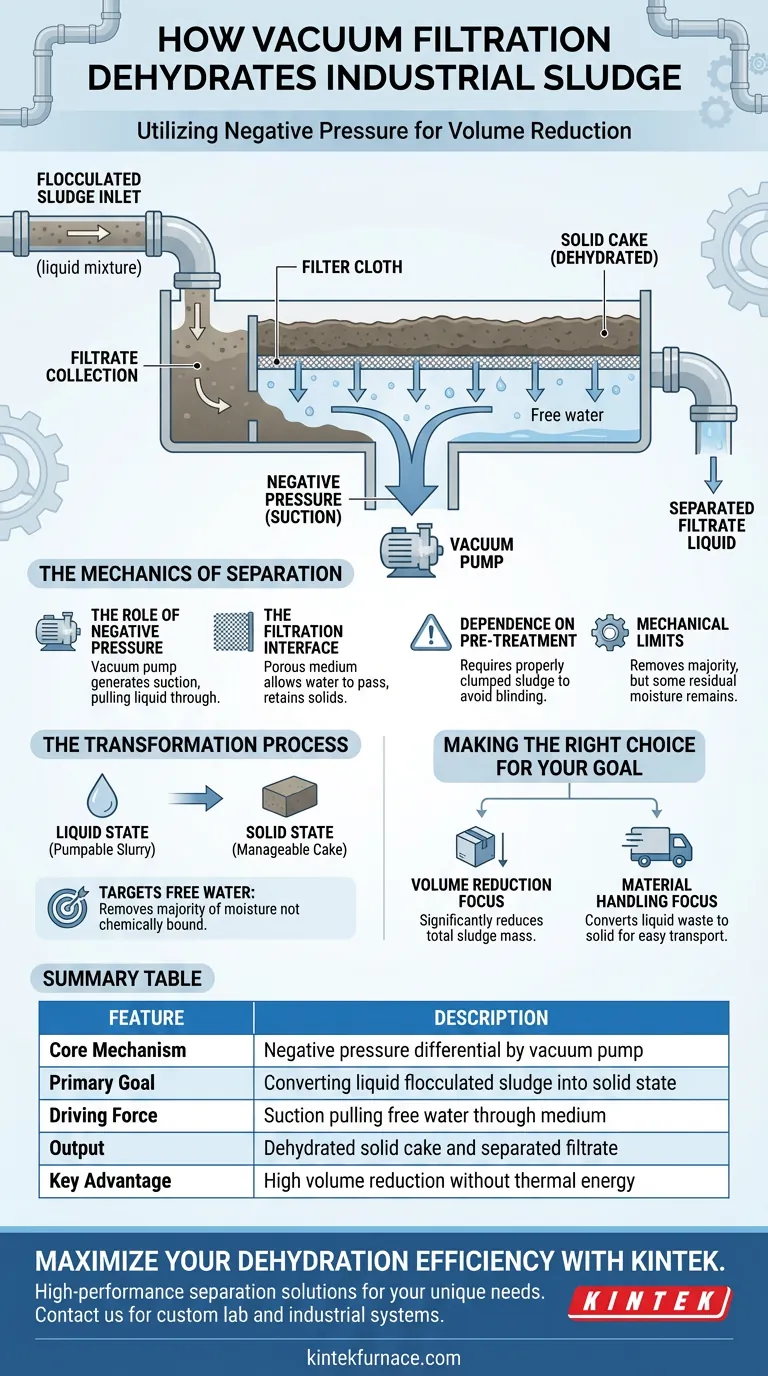

Vacuum filtration systems operate by generating a negative pressure differential. A vacuum pump creates suction that acts as the driving force to pull free water out of industrial sludge and through a porous filtering medium. This mechanical separation is the primary method used to transition sludge from a liquid mixture into a solid form.

By utilizing negative pressure to guide free water through a filter cloth, vacuum filtration effectively removes the majority of moisture from flocculated sludge, converting it into a manageable solid state.

The Mechanics of Separation

The Role of Negative Pressure

The core mechanism of this system is the vacuum pump.

Instead of applying positive pressure to squeeze water out, the pump creates a vacuum (negative pressure) beneath the filtration surface. This suction force actively pulls liquids through the system while leaving solids behind.

The Filtration Interface

The separation physically occurs at the filtering medium, typically a specialized filter cloth.

This medium creates a barrier that allows water to pass through under the influence of the vacuum but retains the solid particles. The efficiency of the system depends heavily on this interface.

Processing Flocculated Sludge

These systems are specifically designed to handle flocculated sludge.

This implies that the sludge has likely been pre-treated to clump particles together. The vacuum system then acts upon this material to separate the free water from the solid aggregates.

The Transformation Process

Transitioning States

The ultimate goal of the operation is a phase change from a liquid state to a solid state.

By removing the liquid carrier, the system converts pumpable slurry into a solid cake that can be handled, transported, or disposed of more easily.

Targeting Free Water

It is important to note that this process specifically targets free water.

The mechanical suction draws out the water that is not chemically bound to the solids. This allows for the removal of the majority of water volume without requiring thermal energy.

Understanding the Limitations

Dependence on Pre-treatment

The system relies on the input being flocculated sludge.

If the sludge is not properly flocculated (clumped), the solids may blind the filter cloth or pass through with the water, compromising the negative pressure efficiency.

Mechanical Limits

While effective, this is a mechanical separation method.

It removes the "majority" of water, but not all of it. It is designed to create a solid state, not a completely dry powder; some residual moisture will always remain after mechanical filtration.

Making the Right Choice for Your Goal

How to Apply This to Your Project

- If your primary focus is volume reduction: Vacuum filtration is highly effective for removing the majority of free water, significantly reducing the total mass of the sludge.

- If your primary focus is material handling: This method is the ideal choice for converting liquid waste into a solid state suitable for transport or landfill.

Effective dehydration relies on maintaining a consistent negative pressure differential to maximize the removal of free water.

Summary Table:

| Feature | Description |

|---|---|

| Core Mechanism | Negative pressure differential generated by a vacuum pump |

| Primary Goal | Converting liquid flocculated sludge into a solid state |

| Driving Force | Suction pulling free water through a filtering medium |

| Output | Dehydrated solid cake and separated filtrate liquid |

| Key Advantage | High volume reduction without the need for thermal energy |

Maximize Your Dehydration Efficiency with KINTEK

Is your lab or industrial process struggling with sludge volume management? At KINTEK, we specialize in high-performance separation solutions. Backed by expert R&D and manufacturing, we offer a comprehensive range of lab equipment including Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet your unique dehydration and thermal processing needs.

Our advanced systems ensure consistent pressure differentials for superior moisture removal, helping you transition liquid waste into manageable solids with ease.

Ready to optimize your workflow? Contact us today to consult with our technical team and find the perfect filtration or high-temp furnace solution for your requirements!

Visual Guide

References

- Jing Ye, Shu-Xu Yi. Laboratory Test of Industrial Waste Mud Treated by the Flocculation-Vacuum-Curing Integrated Method: Deep Dehydration and Preparation of Geopolymer Fluid Solidified Soil. DOI: 10.3390/ma18132961

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- Why are graphite crucible furnaces used in vacuum or protective atmosphere environments? Prevent Oxidation and Ensure Purity

- Why must rare earth-based halide solid electrolytes be handled in a glove box? Protect Your Materials from Degradation

- What are the advantages of a water circulating vacuum pump? Superior for Wet, Corrosive Gas Handling

- What process challenges are addressed by vacuum filtration equipment during the construction of CsPbBr3@CA-SiO2 films?

- Why is a glassy carbon boat preferred over an alumina crucible for Na3Cu4Se4? Ensuring Phase Purity in Flux Synthesis

- What role does a high-purity quartz tube play in flash Joule heating? Ensure Safety and Process Control

- What makes quartz ceramic tubes suitable for high-pressure applications? Key Properties for Demanding Conditions

- Why Use a Capped Alumina Crucible for Glycine Pyrolysis? Optimize Your Carbon-Based Composite Synthesis