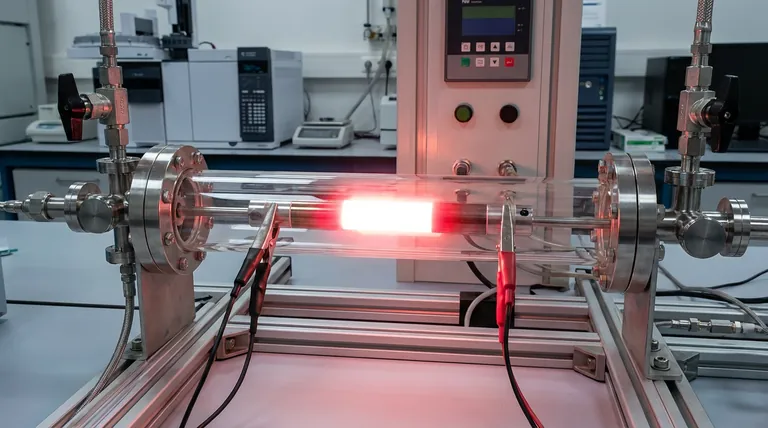

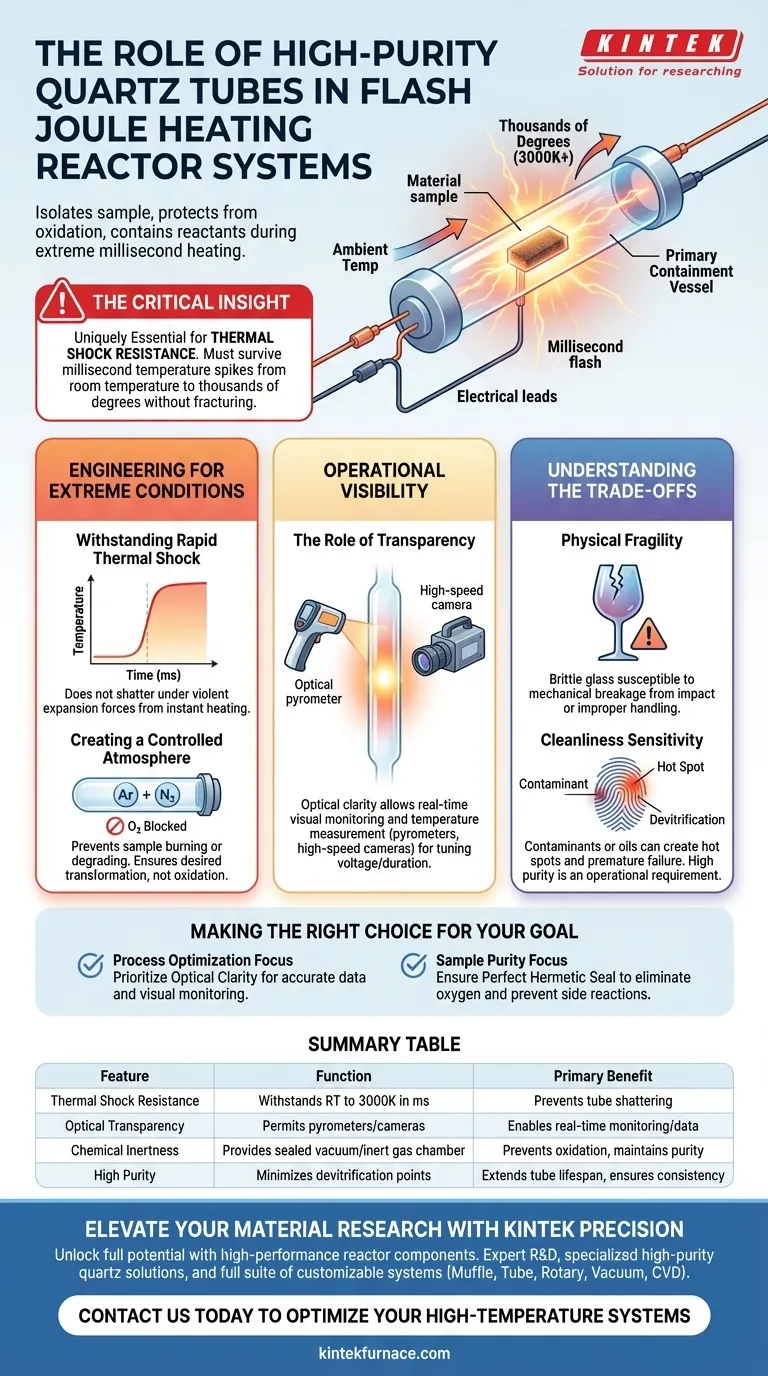

A high-purity quartz tube functions as the primary containment vessel in a flash Joule heating reactor system, isolating the sample in a chemically inert environment. It serves as the physical stage for the reaction, protecting the material from atmospheric oxidation while containing the reactants during the process.

The Critical Insight While many materials offer heat resistance, the high-purity quartz tube is uniquely essential for its thermal shock resistance. It must survive the mechanical stress of temperature spikes from room temperature to thousands of degrees within milliseconds without fracturing.

Engineering for Extreme Conditions

Withstanding Rapid Thermal Shock

The defining characteristic of flash Joule heating is the speed of temperature change. Unlike standard furnaces that heat slowly, this system generates extreme heat in milliseconds.

The quartz tube is selected specifically because it does not shatter under these rapid fluctuations. It maintains structural integrity despite the violent expansion forces associated with instant heating from ambient temperatures to thousands of degrees.

Creating a Controlled Atmosphere

To prevent the sample from burning up or degrading, it must be isolated from external air. The quartz tube provides a sealed, closed environment.

By facilitating a vacuum or inert gas atmosphere, the tube ensures the material undergoes the desired transformation rather than reacting with oxygen. This containment is vital for maintaining the stoichiometry and purity of the final product.

Operational Visibility

The Role of Transparency

Beyond its physical strength, the optical clarity of high-purity quartz is a functional requirement. The tube’s transparency allows operators to visually monitor the reaction in real-time.

This clear line of sight enables the use of optical pyrometers or high-speed cameras to measure temperature and observe the flash. This feedback loop is critical for tuning the voltage and duration of the discharge.

Understanding the Trade-offs

Physical Fragility

Despite its thermal resilience, high-purity quartz remains a brittle glass. It is susceptible to mechanical breakage from physical impact or improper handling during loading and unloading.

Cleanliness Sensitivity

The "high purity" aspect is not just a label; it is an operational requirement. Contaminants or oils from fingerprints on the tube can create hot spots or devitrification sites. These impurities can lead to premature failure of the tube during the high-energy flash.

Making the Right Choice for Your Goal

If you are designing or operating a flash Joule heating system, the quality of the quartz tube dictates the safety and success of the reaction.

- If your primary focus is process optimization: Prioritize the optical clarity of the quartz to ensure accurate temperature data collection and visual monitoring of the flash duration.

- If your primary focus is sample purity: Ensure the tube creates a perfect hermetic seal to completely eliminate oxygen ingress and prevent side reactions during the heating phase.

The high-purity quartz tube is not merely a holder; it is the transparent shield that makes extreme, millisecond-scale chemistry possible.

Summary Table:

| Feature | Function in Flash Joule Heating | Primary Benefit |

|---|---|---|

| Thermal Shock Resistance | Withstands jumps from RT to 3000K in milliseconds | Prevents tube shattering during rapid discharge |

| Optical Transparency | Permits use of pyrometers and high-speed cameras | Enables real-time temperature monitoring and data |

| Chemical Inertness | Provides a sealed vacuum or inert gas chamber | Prevents oxidation and maintains sample purity |

| High Purity | Minimizes devitrification and structural weak points | Extends tube lifespan and ensures reaction consistency |

Elevate Your Material Research with KINTEK Precision

Unlock the full potential of your flash Joule heating applications with high-performance reactor components. Backed by expert R&D and manufacturing, KINTEK offers specialized high-purity quartz solutions along with a full suite of Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable for your unique lab requirements.

Don't compromise on thermal stability or sample purity. Contact us today to optimize your high-temperature systems and see how our engineering expertise can drive your innovation forward.

Visual Guide

References

- Jasreet Kaur, José A. Alarco. Sustainable Manufacturing of Graphitic Carbon from Bio‐Waste Using Flash Heating for Anode Material of Lithium‐Ion Batteries with Optimal Performance. DOI: 10.1002/adsu.202300610

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What are the advantages of using aluminum crucibles for siloxane research? Maximize Thermal Precision and Data Accuracy

- Why is a stainless steel closed-end tube required for controlled atmospheric experiments? Ensure Precise Material Purity

- Why use high-purity graphite for β-Ga2O3 annealing? Key to Thermal Precision & Safety

- What functions do high-strength graphite molds serve in FAST? Optimize Titanium Alloy Consolidation Today

- What key roles do high-purity graphite molds play in SPS? Powering High-Entropy Carbide Synthesis

- What is the function of the substrate heating system for WS2 thin films? Optimize Crystallinity and Adhesion

- How is quartz wool utilized in the assembly of reaction tubes? Optimize Crystal Growth and Flux Separation

- What is the primary function of the transparent quartz tube in the Floating-Zone technique? Optical & Atmospheric Control