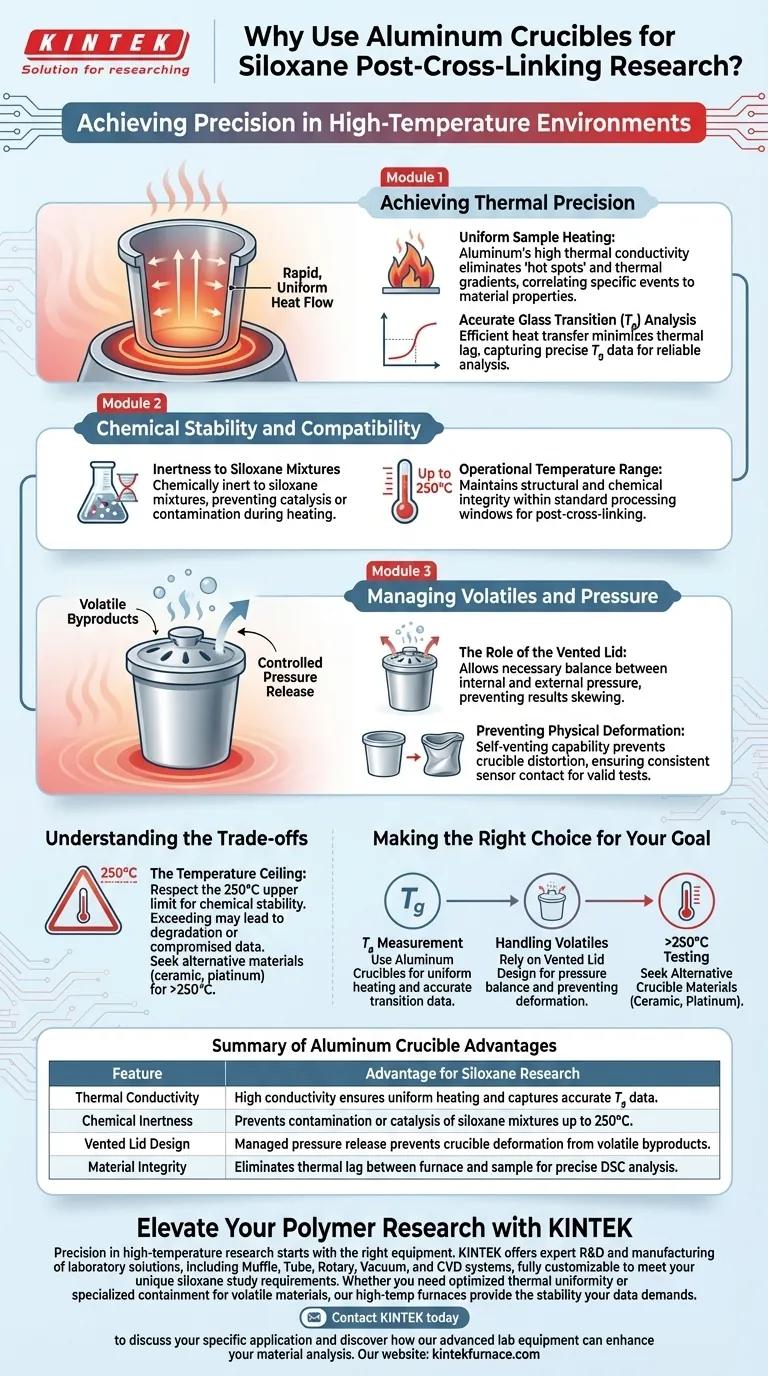

Aluminum crucibles differ significantly from other containment options by offering a precise balance of thermal efficiency and chemical inertness essential for accurate polymer analysis. For post-cross-linking research of siloxane materials, they provide superior thermal conductivity for uniform heating and maintain chemical stability up to 250 °C without reacting with the sample mixture.

Core Takeaway: By combining high thermal conductivity with a vented lid design, aluminum crucibles ensure uniform heating and effective pressure management, resulting in highly accurate glass transition temperature ($T_g$) data for siloxane materials.

Achieving Thermal Precision

Uniform Sample Heating

In Differential Scanning Calorimetry (DSC) and static heat treatments, temperature gradients within a sample can skew data.

Aluminum provides excellent thermal conductivity, ensuring that heat flows quickly and evenly throughout the crucible.

This uniformity eliminates "hot spots" in the siloxane mixture, allowing the researcher to correlate specific thermal events directly to the material's properties rather than experimental artifacts.

Accurate Glass Transition Analysis

The precision of thermal data relies heavily on how the crucible interacts with the heat source.

Because aluminum transfers heat so efficiently, it minimizes thermal lag between the furnace and the sample.

This efficiency is critical for capturing accurate glass transition temperature ($T_g$) data, which is often the primary metric in post-cross-linking research.

Chemical Stability and Compatibility

Inertness to Siloxane Mixtures

Material research requires a container that will not chemically alter the substance being tested.

Aluminum crucibles are chemically inert regarding siloxane mixtures, meaning they will not catalyze unwanted reactions or contaminate the sample during heating.

This neutrality ensures that the observed cross-linking behaviors are intrinsic to the polymer and not influenced by the container material.

Operational Temperature Range

While metals can degrade under stress, aluminum maintains its structural and chemical integrity in specific thermal windows.

These crucibles remain chemically stable at temperatures up to 250 °C.

This range covers the standard processing and testing temperatures for most siloxane post-cross-linking studies.

Managing Volatiles and Pressure

The Role of the Vented Lid

Siloxane curing and cross-linking can release volatile byproducts that build pressure inside a sealed container.

Aluminum crucibles featuring a vented lid design allow for the necessary balance between internal and external pressure.

This venting mechanism allows volatiles to escape in a controlled manner, preventing pressure buildup that could otherwise skew results.

Preventing Physical Deformation

If pressure is not managed, the crucible itself can distort, breaking contact with the sensor or altering the sample geometry.

The self-venting capability prevents crucible deformation caused by these volatile components.

By maintaining its shape, the crucible ensures consistent contact with the thermal sensors, preserving the validity of the test.

Understanding the Trade-offs

The Temperature Ceiling

While aluminum is highly effective for standard polymer research, it has a distinct thermal limit.

You must respect the 250 °C upper limit for chemical stability mentioned in standard protocols.

Exceeding this temperature may lead to crucible degradation or reactions that could compromise the siloxane data.

Making the Right Choice for Your Goal

To ensure your research yields valid, reproducible results, select your equipment based on your specific experimental parameters.

- If your primary focus is accurate $T_g$ measurement: Use aluminum crucibles to ensure uniform heating and eliminate thermal gradients that skew transition data.

- If your primary focus is handling volatiles: Rely on the vented lid design to balance pressure and prevent mechanical deformation of the sample pan.

- If your primary focus is high-temperature testing (>250 °C): You must seek alternative crucible materials (such as ceramic or platinum), as aluminum is no longer chemically stable beyond this point.

Selecting the correct crucible ensures that your data reflects the true properties of the siloxane, not the limitations of your hardware.

Summary Table:

| Feature | Advantage for Siloxane Research |

|---|---|

| Thermal Conductivity | High conductivity ensures uniform heating and captures accurate $T_g$ data. |

| Chemical Inertness | Prevents contamination or catalysis of siloxane mixtures up to 250 °C. |

| Vented Lid Design | Managed pressure release prevents crucible deformation from volatile byproducts. |

| Material Integrity | Eliminates thermal lag between furnace and sample for precise DSC analysis. |

Elevate Your Polymer Research with KINTEK

Precision in high-temperature research starts with the right equipment. Backed by expert R&D and manufacturing, KINTEK offers a wide range of laboratory solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique siloxane study requirements.

Whether you need optimized thermal uniformity or specialized containment for volatile materials, our high-temp furnaces provide the stability your data demands. Contact KINTEK today to discuss your specific application and discover how our advanced lab equipment can enhance your material analysis.

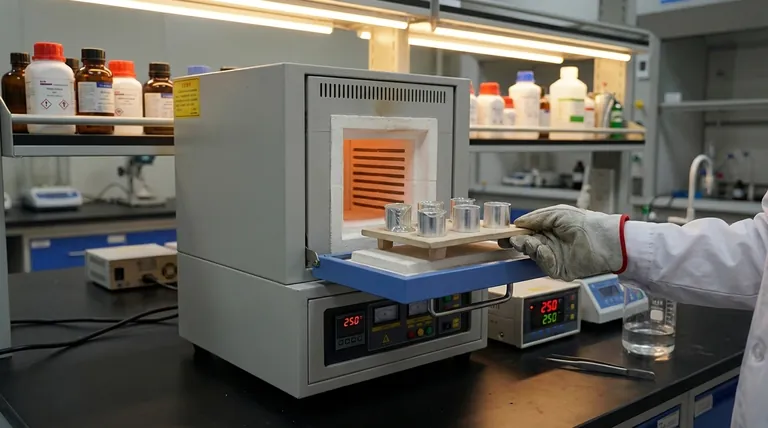

Visual Guide

References

- Max Briesenick, Guido Kickelbick. Thermal Post-Cross-Linking of Siloxane/Silsesquioxane Hybrids with Polycyclic Aromatic Units for Tailored Softening Behavior in High-Temperature Applications. DOI: 10.3390/molecules30173532

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1200℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

People Also Ask

- How does a high-precision laboratory hydraulic press ensure structural consistency? Mastering Ceramic Green Bodies

- What is the function of a laboratory hydraulic press in Al-Cr-Cu-Fe-Mn-Ni alloy formation? Maximize Green Strength

- Why is a Mass Flow Controller (MFC) necessary for CDM testing? Ensure Precise Kinetic Data and Catalyst Performance

- What processes can a circulating water vacuum pump provide negative pressure conditions for? Essential Lab Techniques Explained

- Why is a tantalum (Ta) crucible essential for Li3-3xScxSb sintering? Ensure Pure Phase Stability at 1143 K

- What is the function of a water-cooled copper crucible? Master High-Purity Alloy Synthesis with KINTEK

- Why is radiation correction necessary for K-type thermocouple readings? Ensure Accurate High-Temp Combustion Data

- What is the purpose of using an insulating layer in CCCM thermal conductivity tests? Ensuring 1D Heat Flow Accuracy