In short, a circulating water vacuum pump provides negative pressure for common laboratory processes that benefit from reduced atmospheric pressure. These include evaporation, distillation, crystallization, drying, sublimation, pressure-reducing filtration, and degassing. It is a workhorse for applications that require a moderate, rather than a high, vacuum.

A circulating water vacuum pump is a simple, robust tool for achieving moderate vacuum levels in a lab setting. Its effectiveness hinges on using clean, cool water as its working fluid, making it ideal for standard procedures but less suitable for high-vacuum applications.

How a Circulating Water Vacuum Pump Works

These pumps generate a vacuum not through complex mechanics, but through the elegant principle of fluid dynamics. Understanding this mechanism helps clarify its capabilities and limitations.

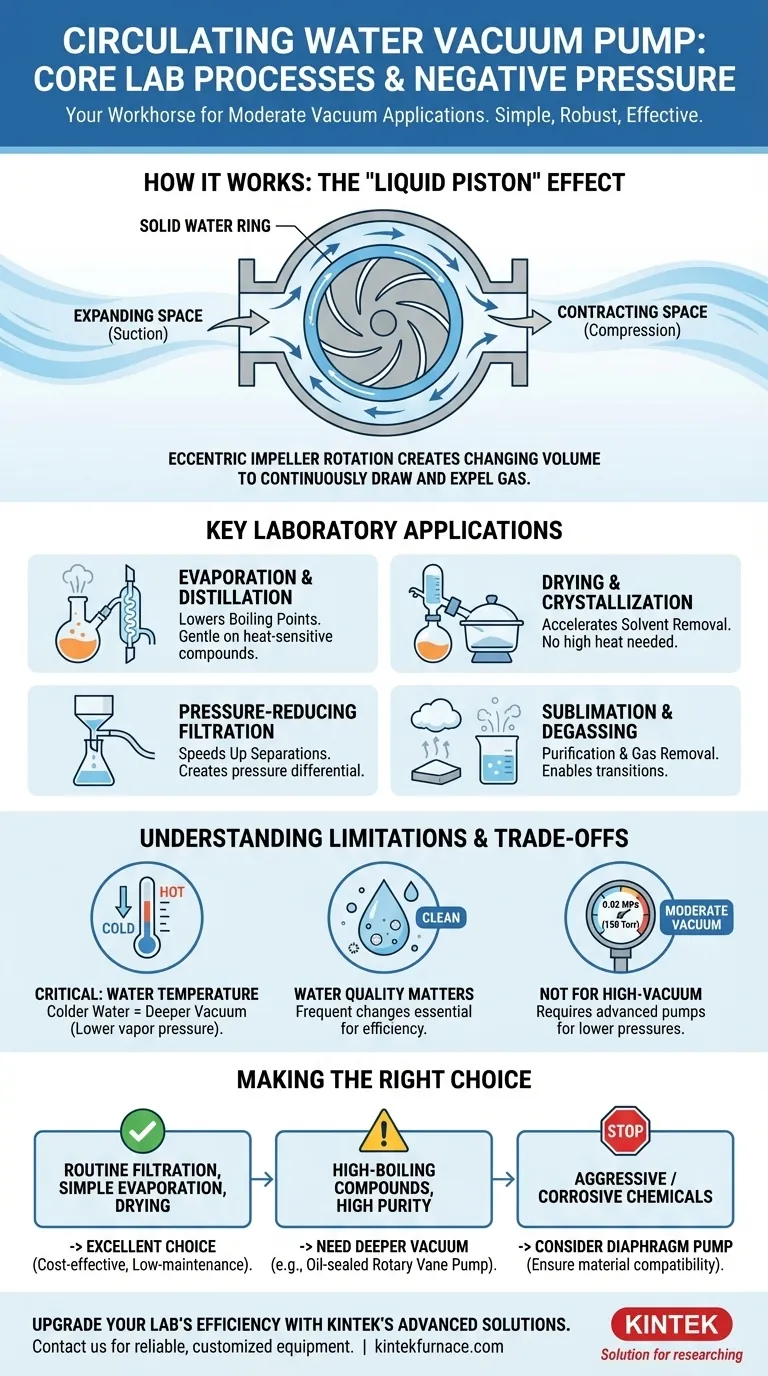

The "Liquid Piston" Effect

The core of the pump is an impeller that spins eccentrically (off-center) inside a cylindrical casing. As it spins, it forces the water against the outer wall, creating a solid, rotating ring of water.

Because the impeller is off-center, the space between the impeller blades and the water ring continuously changes. This space expands on one side of the rotation and contracts on the other.

Creating the Vacuum

This changing volume acts as a "liquid piston." As the space between the blades expands, it draws in gas from the equipment connected to the suction port.

As the impeller continues to rotate, that same pocket of gas becomes trapped and is then compressed as the space contracts, eventually expelling the gas through the exhaust port. This continuous cycle of suction and compression creates a sustained vacuum.

Key Applications in the Laboratory

By lowering the pressure inside a system, a water vacuum pump can dramatically alter physical processes, making it invaluable for numerous techniques.

Evaporation and Distillation

Reducing pressure lowers the boiling point of liquids. This allows you to distill or evaporate heat-sensitive compounds at much lower temperatures, preventing decomposition.

Drying and Crystallization

A vacuum effectively removes solvent vapor from a solid sample. This accelerates the drying process without requiring high heat and is fundamental to techniques like using a rotary evaporator or a vacuum desiccator.

Pressure-Reducing Filtration

Applying a vacuum to the underside of a filter (e.g., in a Büchner funnel setup) creates a significant pressure differential. This pulls the liquid through the filter paper much faster than gravity alone, speeding up separations dramatically.

Sublimation and Degassing

For some solids, a vacuum provides the necessary low-pressure environment to transition directly from a solid to a gas (sublimation), a key purification method. It is also used to remove dissolved gases from liquids before they interfere with other analyses or processes.

Understanding the Trade-offs and Limitations

While highly useful, a circulating water vacuum pump is not the right tool for every job. Its performance is directly tied to the properties of its working fluid—water.

Moderate Vacuum Levels

These pumps typically achieve a moderate vacuum, often cited around 0.02 MPa (150 Torr). This is more than sufficient for filtration but is not a "high vacuum." Processes requiring extremely low pressures, such as in mass spectrometry or certain thin-film depositions, require more advanced pumps like turbomolecular or oil-sealed rotary vane pumps.

Dependence on Water Quality

The pump's efficiency is directly linked to the cleanliness of the circulating water. If the water becomes contaminated with dissolved gases or particulates, its ability to create a stable vacuum diminishes. For this reason, the water should be changed frequently.

The Critical Role of Water Temperature

The ultimate vacuum a water pump can achieve is limited by the vapor pressure of the water itself. Colder water has a lower vapor pressure, which allows the pump to pull a deeper vacuum. Using warm water will significantly degrade performance. Always start with and maintain cool water for best results.

Material and Chemical Compatibility

Gases being evacuated pass through the pump and dissolve in the water. If you are working with highly corrosive gases, they can damage the pump's internal components or contaminate the water, which may then need special disposal. Always verify that the pump's materials are compatible with your chemicals.

Making the Right Choice for Your Goal

Use these guidelines to determine if a circulating water vacuum pump fits your specific needs.

- If your primary focus is routine filtration, simple evaporation, or drying: This pump is an excellent, cost-effective, and low-maintenance choice.

- If your primary focus is separating high-boiling-point compounds or achieving high-purity conditions: You will likely need a pump capable of a deeper vacuum, such as an oil-sealed rotary vane pump.

- If your primary focus is working with aggressive or corrosive chemicals: You must either confirm material compatibility or consider a chemically-resistant diaphragm pump instead.

Selecting the appropriate vacuum source is a critical step in ensuring your scientific process is both efficient and reliable.

Summary Table:

| Process | Key Benefit |

|---|---|

| Evaporation & Distillation | Lowers boiling points for heat-sensitive compounds |

| Drying & Crystallization | Accelerates solvent removal without high heat |

| Pressure-Reducing Filtration | Speeds up liquid separation in setups like Büchner funnels |

| Sublimation & Degassing | Enables solid-to-gas transitions and gas removal from liquids |

Upgrade your lab's efficiency with KINTEK's advanced high-temperature furnace solutions! Our expertise in R&D and in-house manufacturing ensures top-quality products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With strong deep customization capabilities, we tailor solutions to meet your unique experimental needs. Contact us today to discuss how we can support your processes with reliable, customized equipment!

Visual Guide

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does an automatic temperature control system affect bio-char? Engineer Precise Energy Density & Pore Structure

- What function does a planetary ball mill perform in LiFePO4/C synthesis? Optimize Battery Material Conductivity

- What is the purpose of an ultrasonic cleaner in NiMo@Cx catalyst prep? Achieve Uniform Slurry & High-Porosity Coatings

- Why is a quartz boat considered an essential carrier tool for the catalytic pyrolysis synthesis of carbon nanotubes?

- What is the necessity of using vacuum-sealed quartz tubes? Ensuring Integrity in Ti-Cu Alloy Heat Treatment

- What customization options are available for alumina ceramic tubes? Tailor for High-Temp, Corrosion-Resistant Applications

- What are the primary functions of high-purity graphite molds in SPS? Optimize Your Spark Plasma Sintering Process

- Why use graphite or quartz crucibles for liquid antimony-tellurium? Protect Your High-Temp Melt Integrity