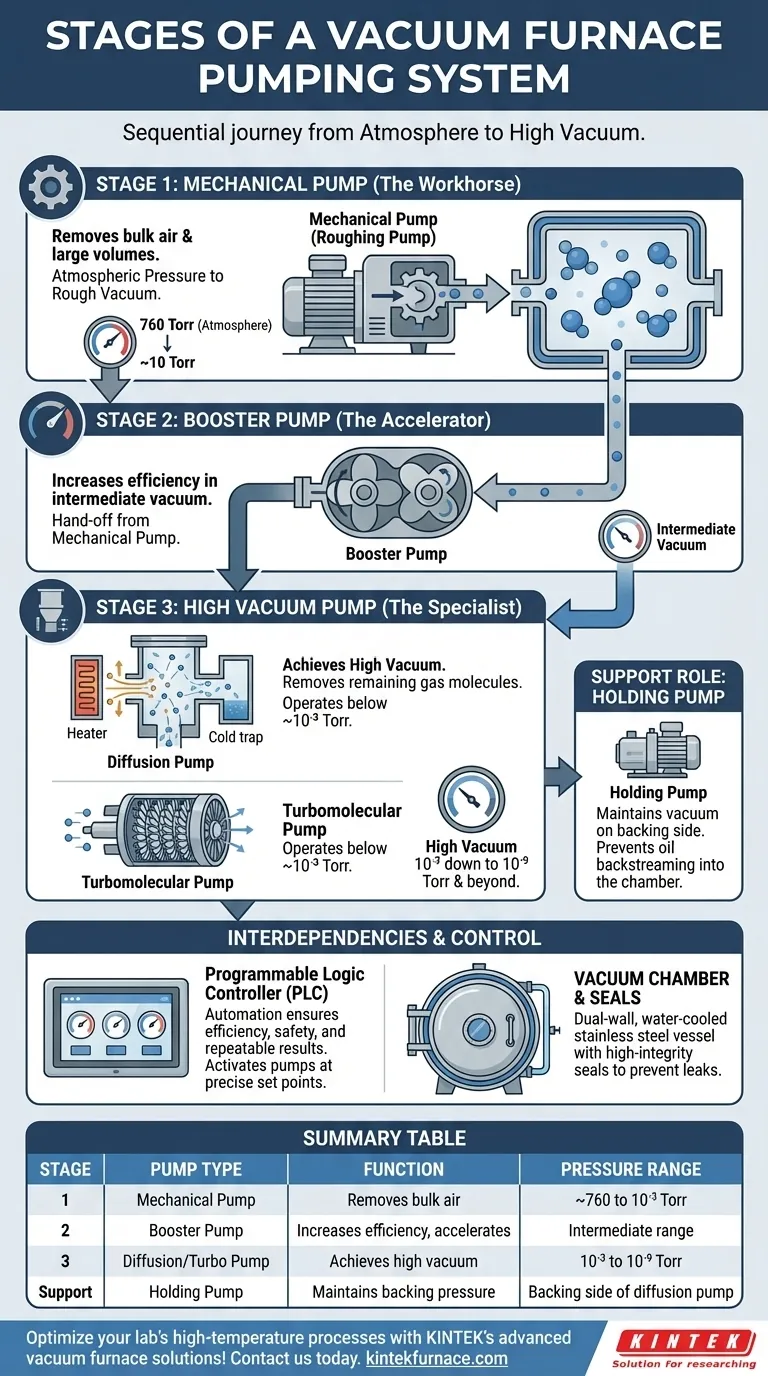

A vacuum furnace pumping system operates in distinct, sequential stages to efficiently remove air and other gases from a sealed chamber. The process begins with a mechanical pump (or "roughing pump") that removes the bulk of the air, followed by a booster pump to increase efficiency in the intermediate vacuum range. For high-vacuum applications, a diffusion pump or turbomolecular pump then takes over to achieve the final low-pressure environment, all while a holding pump maintains correct backing pressure.

No single pump can efficiently operate across the vast pressure range from atmosphere to a high vacuum. A vacuum furnace relies on a multi-stage system where each pump is a specialist, handing off the task to the next in a precisely controlled sequence to progressively reduce the chamber pressure.

Why a Vacuum is Necessary in a Furnace

The primary goal of a vacuum furnace is to create a tightly controlled, inert atmosphere for high-temperature processes like heat treating, brazing, and sintering. Removing the air is the first and most critical step.

Removing Reactive Gases

Atmospheric air is composed primarily of nitrogen and oxygen, which are highly reactive at elevated temperatures. These gases can cause unwanted oxidation, discoloration, and contamination of the material being processed, compromising its structural integrity and surface finish. A vacuum system removes these reactive elements.

Understanding Pressure Ranges

A vacuum is simply a space with a pressure lower than atmospheric pressure (approx. 760 Torr).

- Rough (or Soft) Vacuum is the initial stage, typically down to about 10⁻³ Torr.

- High Vacuum refers to much lower pressures, from 10⁻³ Torr down to 10⁻⁹ Torr and beyond.

Different industrial processes require different vacuum levels, which dictates the complexity of the pumping system needed.

A Sequential Journey from Atmosphere to High Vacuum

The pumping system functions like a relay race. Each pump is optimized for a specific pressure range and hands off the workload to the next pump once its own efficiency starts to decline.

Stage 1: The Mechanical Pump (The Workhorse)

The mechanical pump, often called a "roughing pump," does the initial heavy lifting. It is a positive displacement pump that physically removes large volumes of air from the chamber.

It takes the furnace from atmospheric pressure down into the rough vacuum range, typically stopping around 10 to 20 Torr. At this point, it has removed over 99% of the air molecules, but its ability to pump further diminishes rapidly.

Stage 2: The Booster Pump (The Accelerator)

Once the mechanical pump has reached its effective limit, the booster pump is activated. This pump uses a pair of high-speed, rotating lobes to move gas more efficiently at these lower pressures.

It doesn't exhaust directly to the atmosphere. Instead, it acts as an intermediate stage, pulling gas from the furnace chamber and "boosting" it into the inlet of the mechanical pump. This pairing allows the system to reach the medium vacuum range much faster.

Stage 3: The Diffusion Pump (The High Vacuum Specialist)

To achieve a true high vacuum, a diffusion pump is required. This pump has no moving parts and operates on a different principle entirely. It is only activated once the chamber pressure is already very low (e.g., below 1 micron or 0.001 Torr).

Inside the pump, a special oil is heated until it vaporizes, creating high-velocity jets of vapor. These jets collide with the few remaining gas molecules in the chamber, imparting downward momentum and "dragging" them toward the bottom of the pump, where they are removed by the mechanical/booster pump system (now acting as a "backing pump"). A turbomolecular pump is a common, oil-free alternative that uses high-speed turbine blades to achieve the same effect.

The Support Role: The Holding Pump

A small, dedicated holding pump serves a crucial support function. Its primary job is to maintain vacuum pressure on the backing side of the diffusion pump. This prevents the hot diffusion pump oil from "backstreaming" or migrating back into the main furnace chamber, which would cause catastrophic contamination.

Understanding the System's Interdependencies

The effectiveness of the pumping system is not just about the pumps themselves. It depends on how they are controlled and the integrity of the furnace they are attached to.

The Need for Automation (PLC)

This complex sequence is not managed manually. A Programmable Logic Controller (PLC), operated via a touch-panel interface, automates the entire process.

The PLC monitors pressure via digital gauges and activates each pump only when the correct pressure "set point" is reached. This ensures maximum efficiency, prevents damage to the pumps (a diffusion pump would be destroyed if started at high pressure), and provides repeatable, reliable performance for every cycle.

The Critical Role of the Chamber and Seals

Even the most powerful pumping system is useless if the furnace chamber leaks. Modern vacuum furnace chambers are typically dual-wall, stainless steel constructions with extensive water cooling.

This cooling prevents the chamber from deforming under intense heat and maintains the integrity of the door seals. Without a perfectly sealed, rigid vessel, the pumps would be fighting a losing battle against air leaking back into the system.

Matching the Pumping System to Your Goal

The right system configuration depends entirely on the vacuum level your process demands.

- If your primary focus is basic hardening or tempering (soft vacuum): A single, robust mechanical pump may be sufficient to remove oxygen and prevent scale.

- If your primary focus is high-purity brazing, sintering, or annealing (high vacuum): A full multi-stage system with a mechanical pump, booster, and a diffusion or turbomolecular pump is essential.

- If your primary focus is process consistency and safety: A modern PLC-based control system that automates the entire pump-down and venting sequence is non-negotiable for reliable results.

Ultimately, a vacuum furnace's pumping system is an elegant solution to a complex physics problem, using a team of specialized pumps to create the perfect environment for a flawless result.

Summary Table:

| Stage | Pump Type | Function | Pressure Range |

|---|---|---|---|

| 1 | Mechanical Pump | Removes bulk air from atmosphere to rough vacuum | ~760 to 10⁻³ Torr |

| 2 | Booster Pump | Increases efficiency in medium vacuum, accelerates gas removal | Intermediate range |

| 3 | Diffusion/Turbomolecular Pump | Achieves high vacuum by removing remaining gas molecules | 10⁻³ to 10⁻⁹ Torr |

| Support | Holding Pump | Maintains backing pressure to prevent contamination | Backing side of diffusion pump |

Optimize your lab's high-temperature processes with KINTEK's advanced vacuum furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems tailored to your unique needs. Our strong deep customization capability ensures precise performance for applications like heat treating and sintering. Contact us today to discuss how we can enhance your efficiency and results!

Visual Guide

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What is the primary function of high-purity quartz sealed tubes? Master Sb-Te Alloy Synthesis with Precision Isolation

- What materials are used for the tubes in a High Temperature Tube Furnace? Choose the Right Tube for Your Lab

- What industrial and research applications are tube furnaces used for? Unlock Precise Thermal Processing Solutions

- What is the working principle of a vacuum tube furnace? Master Precise High-Temperature Processing

- What is the function of high-vacuum encapsulated quartz tubes for Ce2(Fe, Co)17? Ensure Phase Purity and Stability