Radiation correction is mandatory in high-temperature flameless combustion because raw thermocouple readings are heavily distorted by radiative heat exchange with furnace walls. In these environments, the thermocouple measures its own thermal equilibrium rather than the actual gas temperature, leading to significant inaccuracies. Without mathematical correction, data interpretation is fundamentally flawed.

In flameless combustion, the probe interacts thermally with the furnace walls just as much as the gas. Applying radiation correction algorithms based on heat balance equations is the only way to eliminate measurement errors of up to 150°C and reveal the true, uniform temperature distribution of the system.

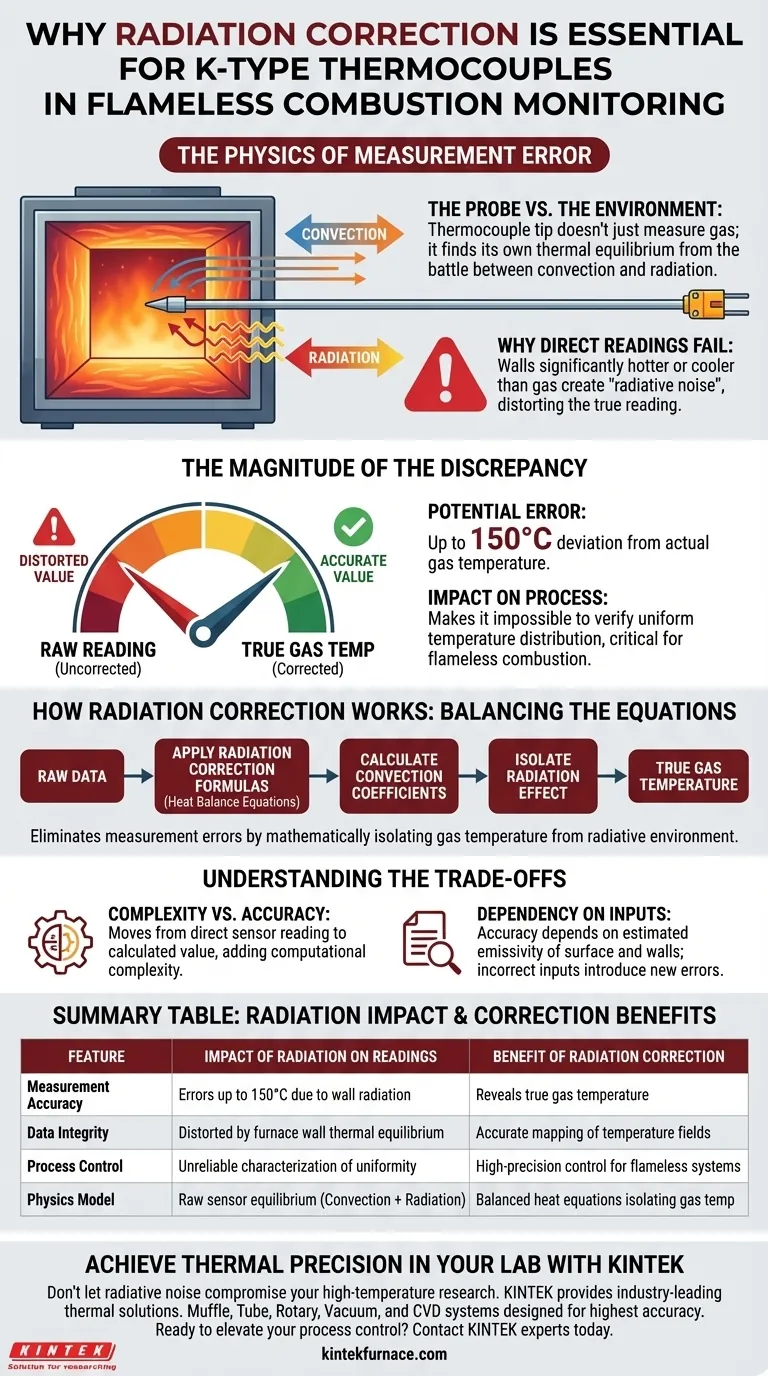

The Physics of Measurement Error

The Probe vs. The Environment

In high-temperature scenarios, a K-type thermocouple is subjected to two competing thermal forces. Convection attempts to bring the probe to the temperature of the gas, while radiation facilitates heat exchange with the surrounding furnace walls.

Why Direct Readings Fail

The thermocouple tip does not simply record the temperature of the air touching it. Instead, it reports its own equilibrium temperature resulting from the battle between convection and radiation.

If the walls are significantly hotter or cooler than the gas, the radiation acts as "noise," pulling the probe's temperature away from the true gas temperature.

The Magnitude of the Discrepancy

Significant Temperature Deviations

The error caused by radiation is not a minor calibration drift. Evidence shows that uncorrected readings can deviate from the actual gas temperature by as much as 150°C.

Impact on Process Characterization

Flameless combustion relies on achieving a highly uniform temperature field. Relying on raw data that is off by such a wide margin makes it impossible to accurately characterize this distribution or verify that uniformity has been achieved.

How Radiation Correction Works

Balancing the Equations

To find the true gas temperature, you must apply radiation correction formulas. This involves integrating surface radiation equations with convection heat balance equations.

Isolating the Variable

By calculating local convection heat transfer coefficients, you can mathematically isolate the effect of radiation. This allows you to subtract the radiative "noise" and determine what the temperature of the gas actually is.

Understanding the Trade-offs

Complexity vs. Accuracy

While correction is necessary for accuracy, it introduces computational complexity. You are moving from a direct sensor reading to a calculated value.

Dependency on Input Variables

The accuracy of the correction depends heavily on the quality of your inputs. If the estimated emissivity of the thermocouple surface or the furnace walls is incorrect, the "corrected" formula may introduce new errors.

Making the Right Choice for Your Goal

To ensure your monitoring system is effective, apply the following guidelines:

- If your primary focus is high-precision process control: You must implement radiation correction algorithms to eliminate the potential 150°C error and accurately map the temperature field.

- If your primary focus is general trend monitoring: You may rely on raw data, but you must conceptually account for a significant margin of error caused by wall radiation.

Accurate monitoring in flameless combustion is not about having better sensors, but about applying the correct physics to isolate the gas temperature from the radiative environment.

Summary Table:

| Feature | Impact of Radiation on Readings | Benefit of Radiation Correction |

|---|---|---|

| Measurement Accuracy | Errors up to 150°C due to wall radiation | Reveals true gas temperature |

| Data Integrity | Distorted by furnace wall thermal equilibrium | Accurate mapping of temperature fields |

| Process Control | Unreliable characterization of uniformity | High-precision control for flameless systems |

| Physics Model | Raw sensor equilibrium (Convection + Radiation) | Balanced heat equations isolating gas temp |

Achieve Thermal Precision in Your Lab with KINTEK

Don't let radiative noise compromise your high-temperature research. KINTEK provides industry-leading thermal solutions backed by expert R&D and manufacturing. Whether you are monitoring flameless combustion or conducting advanced material synthesis, our Muffle, Tube, Rotary, Vacuum, and CVD systems are designed for the highest accuracy and are fully customizable to meet your unique experimental needs.

Ready to elevate your process control? Contact KINTEK experts today to find the perfect high-temperature furnace solution for your laboratory.

Visual Guide

References

- Lizhen Qin, Dong-Hoon Shin. Swirling Flameless Combustion of Pure Ammonia Fuel. DOI: 10.3390/en18123104

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Ultra High Vacuum Stainless Steel KF ISO CF Flange Pipe Straight Pipe Tee Cross Fitting

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What are the advantages of using high-purity graphite molds for transient exothermic welding? Precision & Pure Bonding

- What is the importance of using external thermometers for lead bath monitoring? Ensure Precision in Chemical Refining

- What are alumina ceramic tubes and why are they considered advanced ceramics? Discover High-Performance Solutions for Extreme Environments

- What role does an alumina crucible play during the gas nitriding process for stainless steel? Ensure Surface Purity

- How do gravity-fed cast iron ingot molds affect casting quality? Optimize Aluminum Alloy Microstructure

- What are the technical advantages of using high-purity quartz tubes? Optimize Heat and Purity in Combustion Analysis

- What are the functions of high-purity, high-strength graphite molds in SPS? Optimize Al2O3-TiC Ceramic Sintering

- Why is vacuum sealing in high-purity quartz tubes necessary for the synthesis of FexTaSe2? Master Crystal Growth