The high-purity alumina crucible acts as a chemically inert isolation barrier. During the gas nitriding of stainless steel, its primary function is to serve as a refractory container that carries samples into the heating zone without interacting with them. By remaining non-reactive at high temperatures, the crucible prevents metallic contamination from the furnace environment, ensuring the compositional purity of the steel’s treated surface.

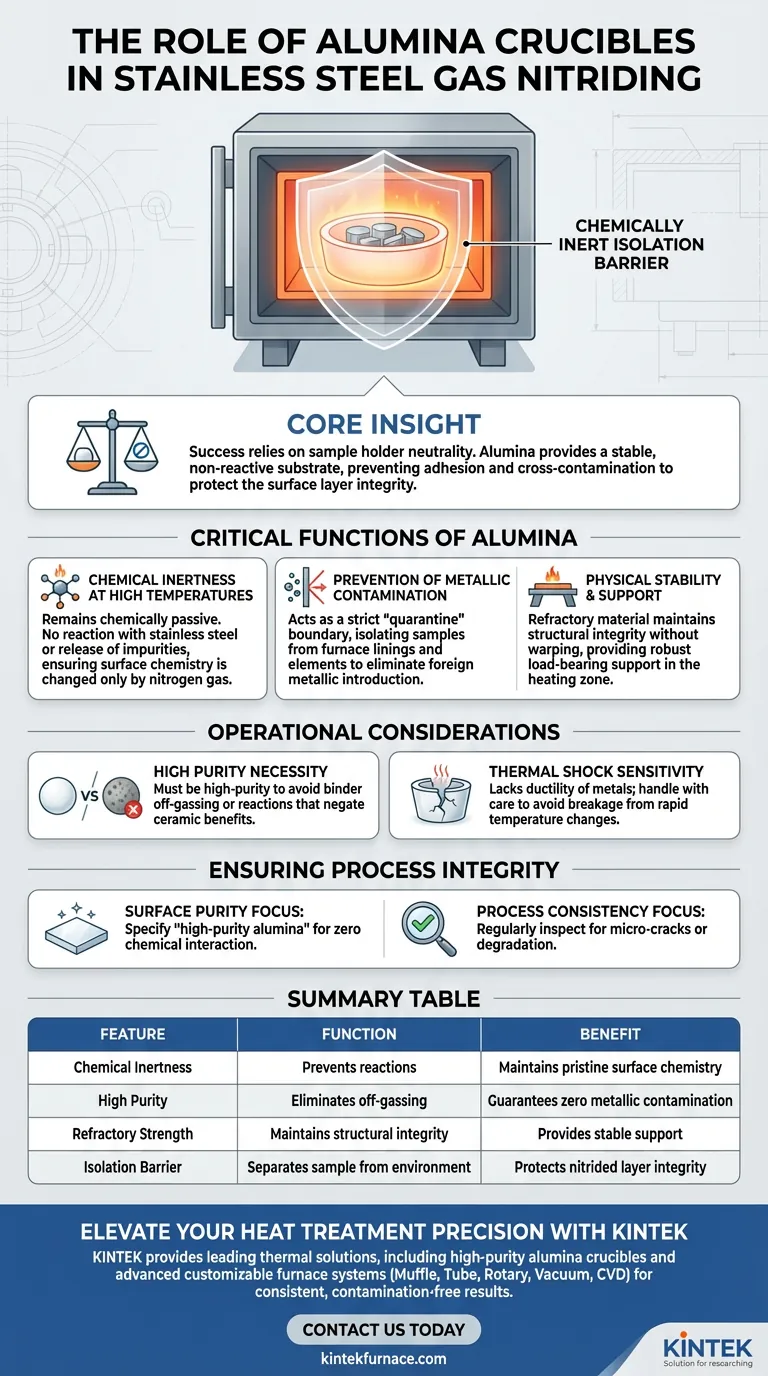

Core Insight: The success of gas nitriding relies on the neutrality of the sample holder. An alumina crucible provides a stable, non-reactive substrate that prevents physical adhesion and chemical cross-contamination, protecting the integrity of the reinforced surface layer.

The Critical Functions of Alumina

Chemical Inertness at High Temperatures

The defining characteristic of an alumina crucible in this process is its exceptional chemical stability. Gas nitriding requires elevated temperatures to diffuse nitrogen into the steel surface.

During this heating phase, the alumina remains chemically passive. It does not release impurities or react with the stainless steel (AISI 304), ensuring that the surface chemistry of the sample is altered only by the nitrogen gas, not by the container holding it.

Prevention of Metallic Contamination

If a reactive metal container were used, ions could migrate between the holder and the sample. Alumina acts as a strict "quarantine" boundary.

By isolating the stainless steel from direct contact with the furnace linings or heating elements, the crucible eliminates the risk of introducing foreign metallic elements into the nitrided layer. This allows for a pristine, reinforced surface solely defined by the intended nitriding process.

Physical Stability and Support

Beyond chemical protection, the crucible serves as a robust load-bearing vessel. It physically transports the samples into the core of the heating zone.

Because alumina is a refractory material, it maintains its structural integrity without softening or warping, even when subjected to thermal environments that might compromise lesser materials.

Operational Considerations

The Necessity of High Purity

Not all alumina is created equal. The process specifically demands high-purity alumina to function correctly.

Lower-grade ceramics may contain binders or impurities that could off-gas or react at nitriding temperatures. Using anything less than high-purity material risks negating the primary benefit of using a ceramic crucible in the first place.

Thermal Shock Sensitivity

While alumina is excellent at withstanding high steady-state temperatures, it is a ceramic material.

This means it generally lacks the ductility of metal containers. Operators must handle these crucibles with care to avoid mechanical breakage or thermal shock caused by extremely rapid temperature changes, which can crack the vessel.

Ensuring Process Integrity

To maximize the effectiveness of your nitriding process, select your crucible based on your specific quality requirements.

- If your primary focus is Surface Purity: Ensure the crucible is specified as "high-purity alumina" to guarantee zero chemical interaction with the stainless steel surface.

- If your primary focus is Process Consistency: Regularly inspect crucibles for micro-cracks or surface degradation, as compromised vessels cannot effectively isolate the sample from the furnace atmosphere.

By utilizing high-purity alumina, you transform the sample holder from a mere container into a critical quality control tool that safeguards the chemistry of your finished product.

Summary Table:

| Feature | Function in Gas Nitriding | Benefit to Stainless Steel |

|---|---|---|

| Chemical Inertness | Prevents reactions between container and sample | Maintains pristine surface chemistry |

| High Purity | Eliminates off-gassing and impurity migration | Guarantees zero metallic contamination |

| Refractory Strength | Maintains structural integrity at high heat | Provides stable support in heating zones |

| Isolation Barrier | Separates sample from furnace environment | Protects the integrity of the nitrided layer |

Elevate Your Heat Treatment Precision with KINTEK

Achieving perfect gas nitriding results requires the right environment and high-performance equipment. KINTEK provides industry-leading thermal solutions, including high-purity alumina crucibles and advanced furnace systems designed for rigorous lab requirements.

Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which are fully customizable to meet your unique materials research needs. Whether you are treating stainless steel or developing new alloys, our equipment ensures consistent, contamination-free results.

Ready to optimize your lab's thermal processes? Contact us today to discuss how our customizable high-temperature furnaces and high-purity ceramics can enhance your production quality.

Visual Guide

References

- G. Keerthi Reddy, Khristina Maksudovna Vafaeva. Influence of aisi 304 austenitic stainless steel by aqueous soluted nitriding and gas nitriding. DOI: 10.1051/matecconf/202439201019

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How does excessive gas purging rate affect the alumina furnace tube? Prevent Cracking and Extend Tube Life

- What is the primary function of a high-purity vacuum-sealed quartz tube in the Modified Bridgman technique? Key Role

- What is the necessity of configuring non-contact infrared pyrometers for temperature monitoring? Ensure Sintering Precision

- What is the significance of using a laboratory electric thermostatic blast drying oven for biomass briquette moisture control?

- How does the dispersion of ruthenium precursors on alumina carriers affect thermal processing in a lab furnace?

- What are the benefits of 150mm thick ceramic fiber blankets in furnaces? Boost Efficiency and Safety

- What is the primary function of a radiation pyrometer in validating furnace simulations? Ensure Model Accuracy

- What are the properties and uses of ceramic tubes? Unlock High-Temp, Insulating Solutions