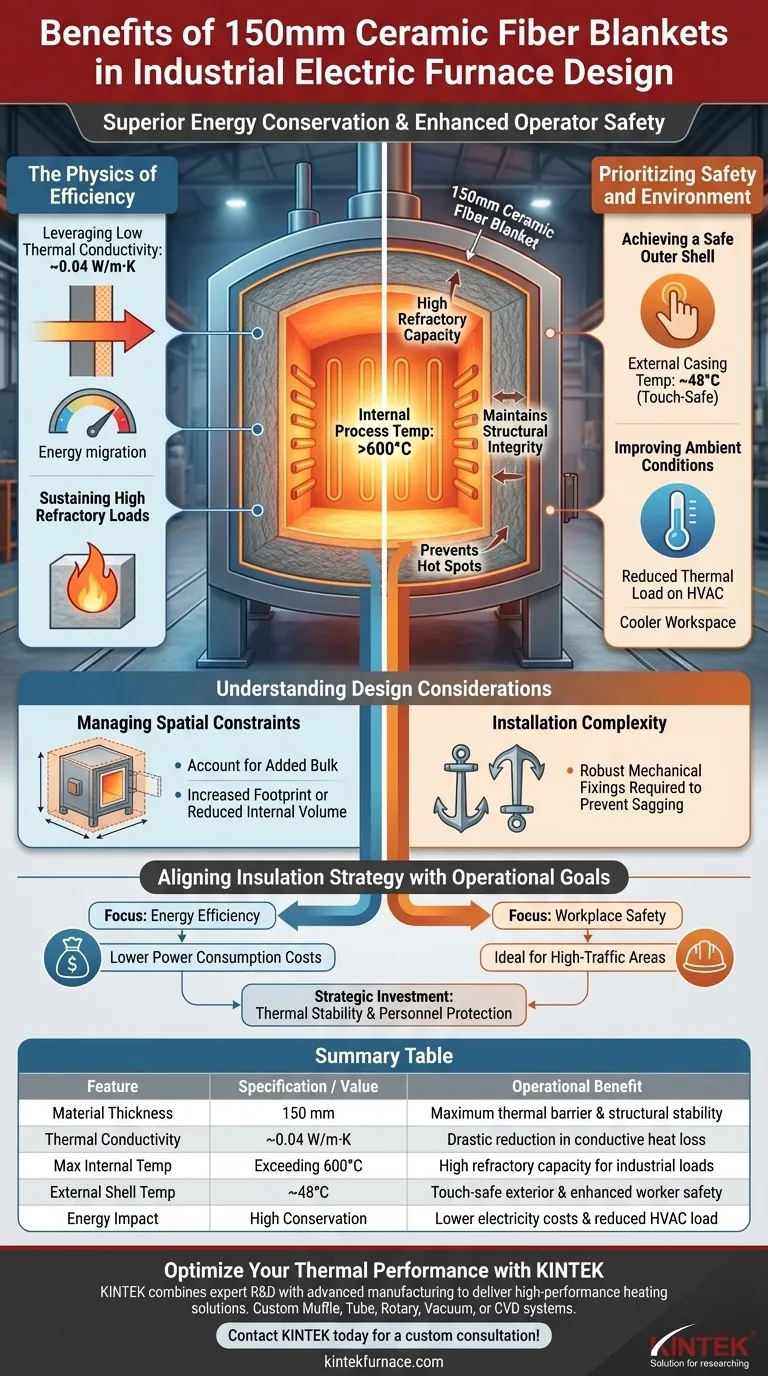

Incorporating a 150mm ceramic fiber blanket into your industrial electric furnace design delivers two critical operational advantages: superior energy conservation and enhanced operator safety. This specific thickness leverages high refractory capacity to dramatically curb conductive heat loss, transforming the furnace's thermal profile.

By utilizing a 150mm profile with a thermal conductivity of roughly 0.04 W/m·K, you can maintain internal process temperatures exceeding 600°C while keeping the external casing at a touch-safe 48°C.

The Physics of Efficiency

Leveraging Low Thermal Conductivity

The core benefit of this material is its remarkably low thermal conductivity, approximately 0.04 W/m·K.

At a thickness of 150mm, this material acts as a robust thermal brake. It minimizes the rate at which heat energy migrates from the furnace core to the exterior, ensuring that energy is used for the process rather than wasted on heating the surrounding environment.

Sustaining High Refractory Loads

Ceramic fiber blankets are engineered with a high refractory capacity, capable of withstanding internal temperatures exceeding 600°C.

The 150mm thickness ensures that the insulation maintains its structural integrity and insulating performance even under these sustained thermal loads. This stability prevents the formation of "hot spots" that can occur with thinner or less resilient materials.

Prioritizing Safety and Environment

Achieving a Safe Outer Shell

Perhaps the most tangible benefit for personnel is the reduction of the outer wall temperature to approximately 48°C.

In industrial environments, hot surfaces are a primary safety hazard. By bringing the shell temperature down to this level, you significantly reduce the risk of contact burns, creating a safer workspace for operators working near the unit.

Improving Ambient Conditions

Reducing heat conduction losses does more than save electricity; it reduces the thermal load on the facility's HVAC system.

By containing the heat within the furnace, the immediate environment remains cooler. This improves operator comfort and protects nearby sensitive equipment from radiant heat damage.

Understanding Design Considerations

Managing Spatial Constraints

While 150mm offers superior insulation, it consumes significant volume.

Engineers must account for this added bulk in the initial design phase. You will need to either increase the total footprint of the furnace or accept a reduction in the usable internal chamber volume to accommodate the thicker lining.

Installation Complexity

Securing a 150mm thick blanket requires careful attention to anchoring systems.

Unlike thinner layers, this substantial thickness requires robust mechanical fixings to prevent sagging or gaps over time, which would compromise the thermal seal.

Aligning Insulation Strategy with Operational Goals

To determine if this specification is right for your project, evaluate your primary objectives:

- If your primary focus is Energy Efficiency: The low conductivity (0.04 W/m·K) of this thickness will drastically lower your ongoing power consumption costs.

- If your primary focus is Workplace Safety: The ability to maintain an outer wall temperature of ~48°C makes this the ideal choice for high-traffic plant floors.

Selecting the 150mm profile is a strategic investment in long-term thermal stability and personnel protection.

Summary Table:

| Feature | Specification / Value | Operational Benefit |

|---|---|---|

| Material Thickness | 150 mm | Maximum thermal barrier & structural stability |

| Thermal Conductivity | ~0.04 W/m·K | Drastic reduction in conductive heat loss |

| Max Internal Temp | Exceeding 600°C | High refractory capacity for industrial loads |

| External Shell Temp | ~48°C | Touch-safe exterior & enhanced worker safety |

| Energy Impact | High Conservation | Lower electricity costs & reduced HVAC load |

Optimize Your Thermal Performance with KINTEK

Ready to elevate your lab's efficiency and safety? KINTEK combines expert R&D with advanced manufacturing to deliver high-performance heating solutions. Whether you need Muffle, Tube, Rotary, Vacuum, or CVD systems, our high-temperature furnaces are fully customizable to meet your specific insulation and process requirements.

Maximize your energy savings and protect your team—Contact KINTEK today for a custom consultation!

Visual Guide

References

- Gustavo Ribeiro Zanini, LUIS CARLOS GERON. PROJETO DE UM FORNO ELÉTRICO INDUSTRIAL PARA TRATAMENTO TÉRMICO TUBOS DE AÇO SA-178 GR A. DOI: 10.52138/citec.v17i01.437

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What manufacturing processes rely on laboratory furnaces? Precision Heat Treatment for Advanced Materials

- Why are sealed Niobium (Nb) tubes utilized as reaction vessels during the high-temperature solid-state synthesis of Ba1-xEuxZn2Sb2?

- Why are quartz tubes suitable for material research applications? Ensure Purity and Precision in High-Temp Experiments

- Why is a Boron Nitride coating applied to graphite crucibles for Mg3Sb2 alloys? Protect Purity and Tooling

- How is a precision gas flow control system configured for calcium carbonate decomposition? Master Industrial Kinetics

- What role does an alumina crucible play during the gas nitriding process for stainless steel? Ensure Surface Purity

- How does an infrared (IR) pyrometer improve thermal control? Direct Precision for MBE Growth and Annealing

- What is the function of laboratory pellet presses and steel dies? Maximize Reaction Kinetics in Oxide Processing