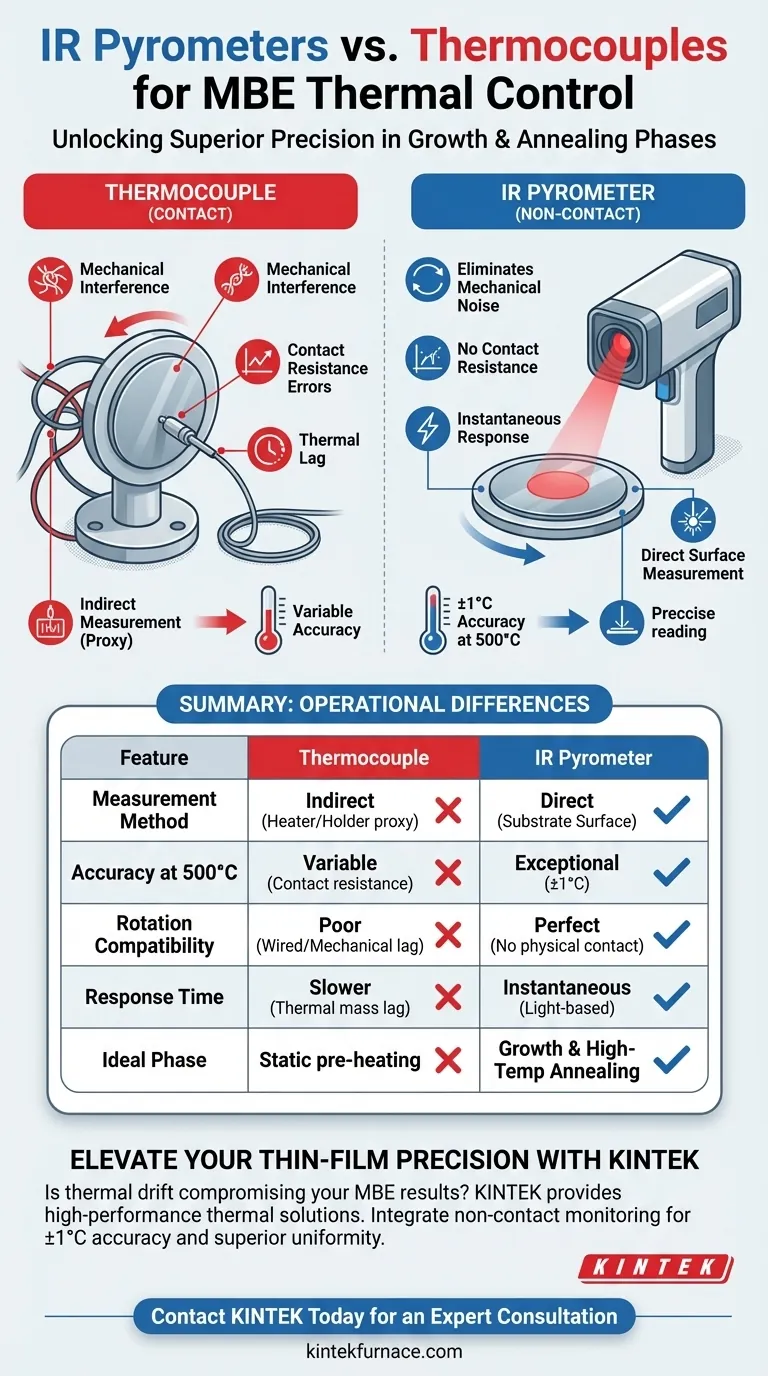

Infrared (IR) pyrometers fundamentally improve thermal control by providing a non-contact, direct measurement of the substrate's actual surface temperature. Unlike thermocouples, which are prone to errors caused by contact resistance and the mechanical challenges of rotating substrates, pyrometers deliver real-time monitoring with exceptional precision, achieving an accuracy of ±1°C at deposition temperatures of 500°C.

The transition from thermocouples to IR pyrometers shifts the process from inferring temperature via physical contact to measuring the actual surface state directly. This eliminates mechanical interference and thermal lag, ensuring the stability required for critical MBE growth and annealing phases.

Overcoming the Limitations of Contact Measurement

Eliminating Contact Resistance

Thermocouples rely on physical touch to measure heat. This introduces contact resistance, a variable that causes discrepancies between the sensor's reading and the actual temperature of the material.

IR pyrometers bypass this issue entirely. By measuring thermal radiation remotely, they provide a true reading of the substrate surface without the errors introduced by physical interfaces.

Facilitating Substrate Rotation

Uniform material growth in Molecular Beam Epitaxy (MBE) often requires the substrate to rotate. Traditional wired thermocouples are mechanically ill-suited for rotating stages, often leading to signal noise or complex slip-ring requirements.

Because IR pyrometers are non-contact devices, they remain unaffected by the mechanical movement of the substrate. This allows for continuous, uninterrupted monitoring regardless of rotation speed.

Precision in Critical Process Phases

High-Accuracy Deposition

Stable material growth demands tight thermal tolerances. The primary reference confirms that IR pyrometers can maintain an accuracy of ±1°C at deposition temperatures of 500°C.

This level of precision ensures that the growth kinetics remain constant. It prevents temperature drifts that could alter the crystal structure or stoichiometry of the layer being deposited.

Control During High-Temperature Annealing

The benefits of direct surface measurement extend beyond the initial growth. During high-temperature annealing stages, precise thermal profiles are necessary to activate dopants or cure defects.

Pyrometers provide real-time feedback during these rapid temperature changes. This allows the control system to react instantly to the actual surface temperature, rather than waiting for heat to soak through to a backside thermocouple.

Understanding the Operational Differences

Direct Surface vs. Indirect Proxy

The most significant distinction is what is actually being measured. Thermocouples typically measure the back of a wafer holder or a heater element, serving as a proxy for the substrate temperature.

In contrast, IR pyrometers measure the substrate surface directly. This removes the guesswork regarding thermal transfer efficiency between the heater and the wafer, providing the data that actually matters for the physics of the growth process.

Real-Time Responsiveness

Thermocouples have thermal mass, which induces a lag in response time. If the heater power changes, the thermocouple takes time to register the shift.

IR pyrometers offer real-time monitoring. Because they detect light (infrared radiation), the feedback is instantaneous, allowing for tighter closed-loop control of the growth environment.

Making the Right Choice for Your Goal

To optimize your MBE process, align your instrumentation with your specific constraints:

- If your primary focus is Uniformity via Rotation: Switch to IR pyrometers to eliminate the mechanical noise and connection issues inherent to using thermocouples on rotating stages.

- If your primary focus is Process Stability: leverage the ±1°C accuracy of pyrometers to ensure the actual surface temperature matches your setpoint, eliminating contact resistance errors.

Adopting non-contact pyrometry transforms thermal management from a reactive estimation to a precise, proactive control strategy.

Summary Table:

| Feature | Thermocouple (Contact) | IR Pyrometer (Non-Contact) |

|---|---|---|

| Measurement Method | Indirect (Heater/Holder proxy) | Direct (Substrate Surface) |

| Accuracy at 500°C | Variable (Contact resistance) | Exceptional (±1°C) |

| Rotation Compatibility | Poor (Wired/Mechanical lag) | Perfect (No physical contact) |

| Response Time | Slower (Thermal mass lag) | Instantaneous (Light-based) |

| Ideal Phase | Static pre-heating | Growth & High-Temp Annealing |

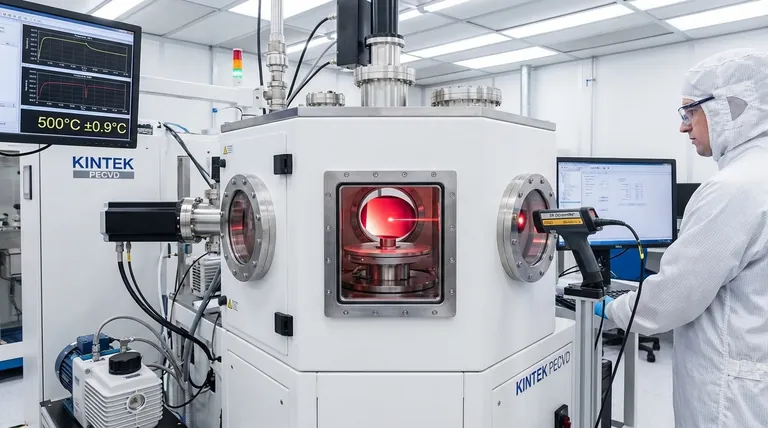

Elevate Your Thin-Film Precision with KINTEK

Is thermal drift compromising your MBE growth or annealing results? KINTEK provides high-performance thermal solutions designed for the most demanding laboratory environments. Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, along with specialized heating components that are fully customizable to your unique research needs.

Don't settle for indirect measurements and mechanical interference. Let our team help you integrate the precision of non-contact monitoring into your workflow to ensure ±1°C accuracy and superior material uniformity.

Ready to optimize your lab's thermal control? Contact KINTEK Today for a Expert Consultation

Visual Guide

References

- Emanuele Pompei, Stefano Veronesi. Novel Structures of Gallenene Intercalated in Epitaxial Graphene. DOI: 10.1002/smll.202505640

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- Why is the precision of a Mass Flow Controller (MFC) critical for ethanol vapor detection? Master Accurate Gas Mixing

- Why are high-purity zirconia grinding balls preferred over steel? Achieve Ultra-Pure Ceramic Grinding Results

- What role does a high-precision constant temperature drying oven play in battery electrode preparation? Master Battery Performance

- Why is graphite foil used to line graphite molds before loading titanium alloy powder? Ensure Purity and Protect Molds

- What is the key role of a vacuum filter in a waste magnesium vacuum distillation system? Protecting Your Pumps from Catastrophic Damage

- How do recirculating coolant baths and glass bottles improve CHP? Boost Bio-oil Yield with Precision Cooling

- What is the primary function of the transparent quartz tube in the Floating-Zone technique? Optical & Atmospheric Control

- How does choosing alumina vs graphite crucibles affect Al-Si melting? Expert Guide to Data Integrity