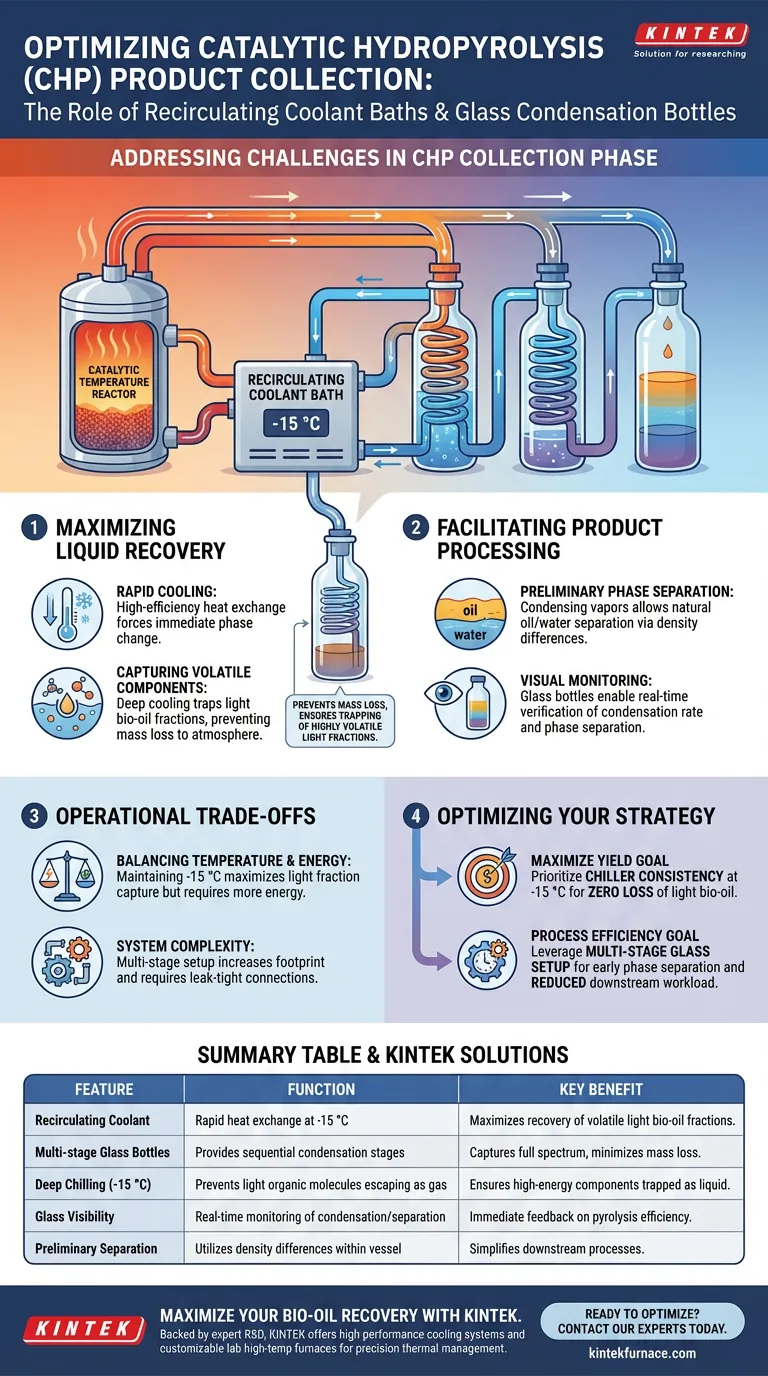

Recirculating coolant baths and glass condensation bottles serve as the critical interface between high-temperature reactions and tangible product recovery in Catalytic Hydropyrolysis (CHP). By employing a multi-stage system that chills vapors to as low as -15 °C, this setup addresses the twin challenges of maximizing bio-oil yield and managing phase separation.

The primary function of this cooling assembly is not merely temperature reduction, but the prevention of mass loss; it ensures that highly volatile light fractions are trapped as liquid rather than escaping as gas.

Maximizing Liquid Recovery

The Role of Rapid Cooling

The core challenge in CHP collection is the transition from high-temperature pyrolysis vapors to stable liquids. Recirculating coolant baths provide a high-efficiency heat exchange environment.

By circulating coolant at temperatures as low as -15 °C, the system forces a rapid phase change. This immediate drop in thermal energy is essential for condensing both organic components and water vapor simultaneously.

Capturing Volatile Components

Without aggressive cooling, lighter organic molecules often remain in the vapor phase and are lost to the atmosphere.

The use of multi-stage glass collection bottles combined with deep cooling traps these volatile components. This specifically prevents the loss of light bio-oil fractions, which are often the most valuable high-energy components of the product slate.

Facilitating Product Processing

Preliminary Phase Separation

Collecting the product is only half the battle; separating the useful oil from the byproduct water is the next step.

This collection method facilitates the preliminary separation of aqueous and organic phases. By condensing both vapors into the glass bottles, the natural density differences allow the oil and water to begin separating immediately within the collection vessel.

Visual Monitoring

The use of glass condensation bottles offers a distinct operational advantage.

It allows operators to visually verify the condensation rate and observe the phase separation in real-time. This provides immediate feedback on the efficiency of the upstream pyrolysis reaction.

Operational Trade-offs

Balancing Temperature and Energy

While achieving temperatures of -15 °C maximizes the capture of light fractions, it requires a robust recirculating chiller system.

There is a direct trade-off between the energy required to maintain sub-zero temperatures and the incremental yield gained from capturing the lightest volatiles.

System Complexity

Implementing a multi-stage collection system increases the physical footprint and complexity of the apparatus compared to a single-stage condenser.

Operators must ensure leak-tight connections across multiple glass stages to prevent the escape of vapors or the ingress of air, which could compromise the sample quality.

Optimizing Your Collection Strategy

To ensure your CHP process meets its recovery targets, evaluate your cooling requirements based on your specific yield goals.

- If your primary focus is Maximizing Yield: Prioritize the chiller's ability to maintain -15 °C consistently to ensure zero loss of light bio-oil fractions.

- If your primary focus is Process Efficiency: Leverage the multi-stage glass setup to initiate phase separation early, reducing the workload on downstream separation equipment.

Effective CHP product collection relies on the precise thermal management of vapors to secure the full spectrum of bio-oil components.

Summary Table:

| Feature | Function in CHP Collection | Key Benefit |

|---|---|---|

| Recirculating Coolant | Rapid heat exchange at temperatures as low as -15 °C | Maximizes recovery of volatile light bio-oil fractions |

| Multi-stage Glass Bottles | Provides sequential condensation stages | Captures the full spectrum of products and minimizes mass loss |

| Deep Chilling (-15 °C) | Prevents light organic molecules from escaping as gas | Ensures high-energy components are trapped as liquid |

| Glass Visibility | Real-time monitoring of condensation and phase separation | Provides immediate feedback on pyrolysis reaction efficiency |

| Preliminary Separation | Utilizes density differences within the collection vessel | Simplifies downstream oil-water separation processes |

Maximize Your Bio-oil Recovery with KINTEK

Don't let valuable high-energy fractions escape your collection system. Backed by expert R&D and manufacturing, KINTEK offers high-performance cooling systems and customizable lab high-temp furnaces, including Muffle, Tube, Rotary, Vacuum, and CVD systems. Our precision thermal management solutions are designed to help researchers achieve zero mass loss and superior phase separation in complex processes like Catalytic Hydropyrolysis (CHP).

Ready to optimize your lab's collection efficiency? Contact our experts today to build a tailored high-temperature and cooling setup for your unique research needs!

Visual Guide

References

- Hoda Shafaghat, Olov Öhrman. Customized Atmospheric Catalytic Hydropyrolysis of Biomass to High-Quality Bio-Oil Suitable for Coprocessing in Refining Units. DOI: 10.1021/acs.energyfuels.3c05078

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Small Rotary Kiln Calciner

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the technical significance of using a quartz boat in 2D superlattice preparation? Enhancing CVD Precision

- What are the advantages of using open corundum crucibles for thermal analysis? Accurate Biomass & Coal Data

- What precautions should be taken when using the alumina furnace tube for the first time? Ensure Safe Initial Use with Proper Conditioning

- What is the point of a vacuum chamber? Achieve Absolute Control in Your Processes

- How do industrial sealing clamps and O-ring systems ensure process repeatability? Achieve Consistent Sintering Quality

- Why must alloy samples be sealed in vacuum-evacuated fused silica containers during diffusion annealing processes?

- Why are high-purity quartz tubes used in combustion furnaces? Unlock Precise Optical Diagnostics and Purity

- What are the advantages of using aluminum crucibles for siloxane research? Maximize Thermal Precision and Data Accuracy