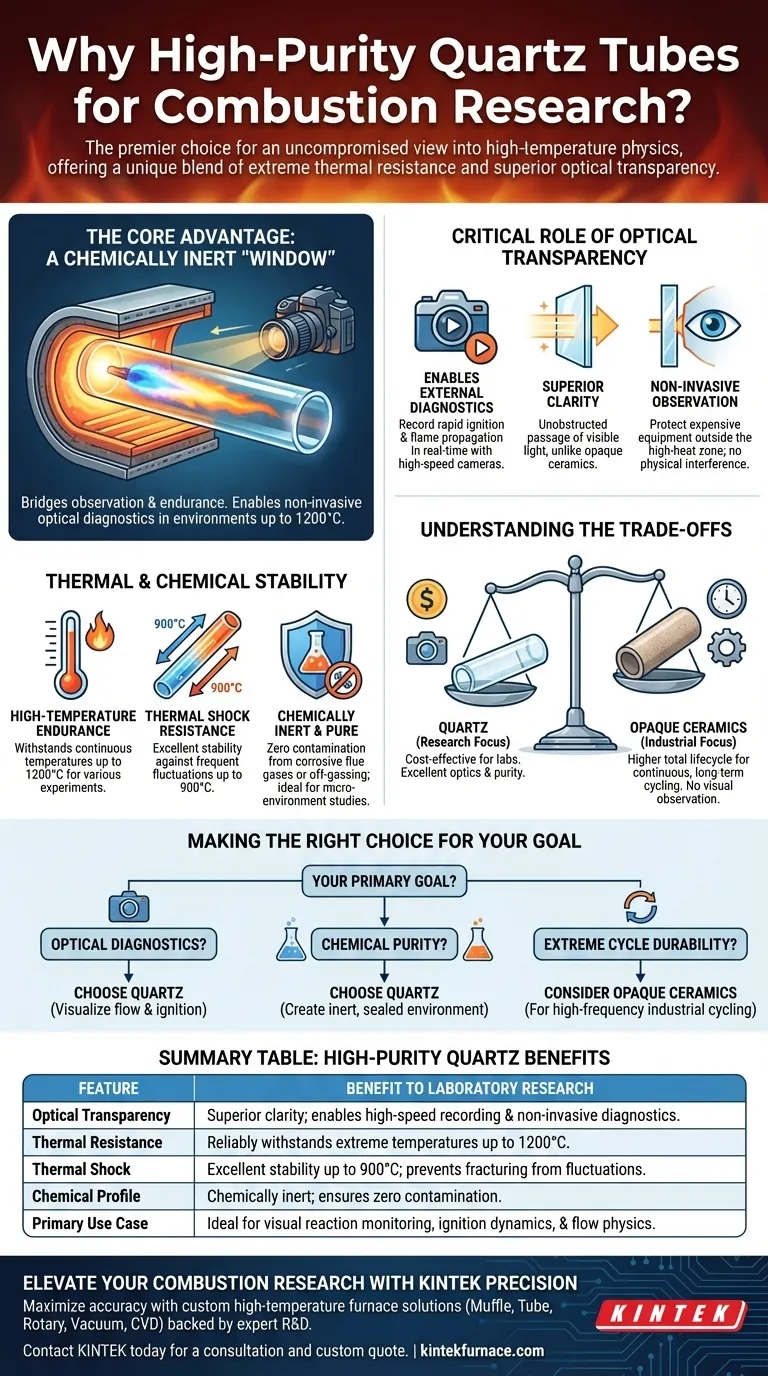

High-purity quartz tubes are selected as combustion reaction chambers primarily because they offer a unique combination of extreme thermal resistance and superior optical transparency. This material allows researchers to visually monitor and record internal ignition dynamics using external devices while ensuring the chemical composition of the reaction remains uncontaminated.

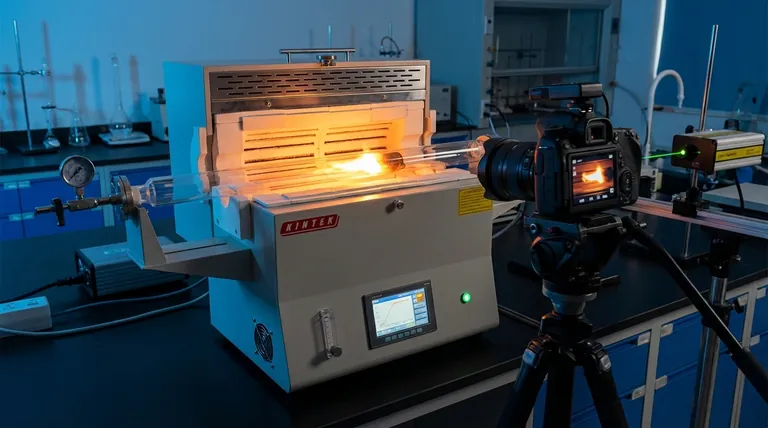

High-purity quartz bridges the gap between observation and endurance, allowing optical diagnostics in environments up to 1200°C. Its value lies in providing a chemically inert "window" into the combustion process that opaque ceramic alternatives cannot offer.

The Critical Role of Optical Transparency

Enabling External Diagnostics

The most distinct advantage of high-purity quartz is its superior optical transparency. Unlike opaque ceramic chambers, quartz allows visible light to pass through the furnace walls unobstructed.

Recording Rapid Ignition Events

This transparency is essential for utilizing external optical devices, such as high-speed cameras. Researchers can record ignition signals and flame propagation in real-time without inserting probes that might disturb the flow.

Non-Invasive Observation

By keeping instrumentation outside the high-heat zone, you protect expensive equipment while capturing data. This setup eliminates physical interference with the combustion process inside the tube.

Thermal and Chemical Stability

High-Temperature Endurance

Quartz tubes are engineered to withstand rigorous thermal environments. They are generally suitable for applications reaching up to 1200°C, making them viable for a wide range of combustion experiments.

Thermal Shock Resistance

Beyond steady-state heat, these tubes demonstrate excellent thermal shock stability. In experimental settings up to 900°C, they can endure frequent temperature fluctuations without fracturing.

Chemical Inertness

Accuracy in combustion analysis relies on a pure reaction atmosphere. High-purity quartz is chemically inert, meaning it does not react with the corrosive flue gases often produced during fuel combustion.

Preventing Sample Contamination

The material’s stability prevents the tube itself from off-gassing or introducing impurities. This is critical for micro-environment studies, such as vacuum-sealed experiments involving aluminum alloys, where external contamination must be strictly blocked.

Understanding the Trade-offs

Lifecycle Limitations

While quartz handles thermal shock well, it is not invincible. A general limitation is that quartz typically cannot withstand as many total heat-cool cycles over its lifespan compared to certain advanced opaque ceramics.

Cost vs. Longevity

Quartz is often a cost-effective option for laboratories. However, for industrial processes requiring continuous, long-term cycling without visual observation, other materials may offer greater durability.

Making the Right Choice for Your Goal

To determine if high-purity quartz is the correct material for your specific furnace application, consider your primary experimental needs.

- If your primary focus is Optical Diagnostics: Choose quartz to enable the use of high-speed cameras and laser diagnostics for visualizing flow and ignition.

- If your primary focus is Chemical Purity: Rely on quartz to create a chemically inert, sealed micro-environment that prevents reaction with corrosive flue gases.

- If your primary focus is Extreme Cycle Durability: Be aware that while quartz resists thermal shock, it may have a shorter total service life than opaque ceramics in high-frequency cycling applications.

High-purity quartz remains the premier choice for researchers who require an uncompromised view of the physics occurring inside the reactor.

Summary Table:

| Feature | High-Purity Quartz Tube | Benefit to Laboratory Research |

|---|---|---|

| Optical Transparency | Superior clarity (Visible light) | Enables high-speed camera recording & non-invasive flame diagnostics |

| Thermal Resistance | Up to 1200°C | Withstands extreme combustion temperatures reliably |

| Thermal Shock | Excellent stability up to 900°C | Prevents fracturing during frequent temperature fluctuations |

| Chemical Profile | Chemically inert | Ensures zero contamination from corrosive flue gases or off-gassing |

| Primary Use Case | Visual reaction monitoring | Ideal for studying ignition dynamics and flow physics |

Elevate Your Combustion Research with KINTEK Precision

Maximize your experimental accuracy with high-purity quartz solutions tailored for high-temperature environments. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you need standard lab high-temp furnaces or fully customizable systems to meet unique research parameters, our team provides the technical expertise to ensure your success.

Ready to optimize your thermal processes? Contact KINTEK today for a consultation and custom quote.

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- Why is it necessary to use a mechanical vacuum pump for SnSe growth? Ensure High-Purity Material Synthesis

- What is the purpose of using a high-purity ceramic crucible with a sealed lid during the thermal treatment of biochar?

- What are the main applications of laboratory furnaces? Unlock Precision Heat Processing for Your Lab

- What are the different grades of Alumina ceramic and how do they differ? Choose the Right Grade for Your Needs

- How does a Mass Flow Controller (MFC) regulate TCNF morphology? Achieve Precise Carbon Nanofiber Growth

- Why are high-purity graphite molds essential for the sintering of Tin Selenide (SnSe) alloys? Key to Precise SPS Results

- Why must the reaction containers be sealed within a fused quartz tube? Protect Your Crystal Growth Integrity

- What is the purpose of a laboratory vacuum system in photocatalytic hydrogen evolution? Ensure Accurate Data Results