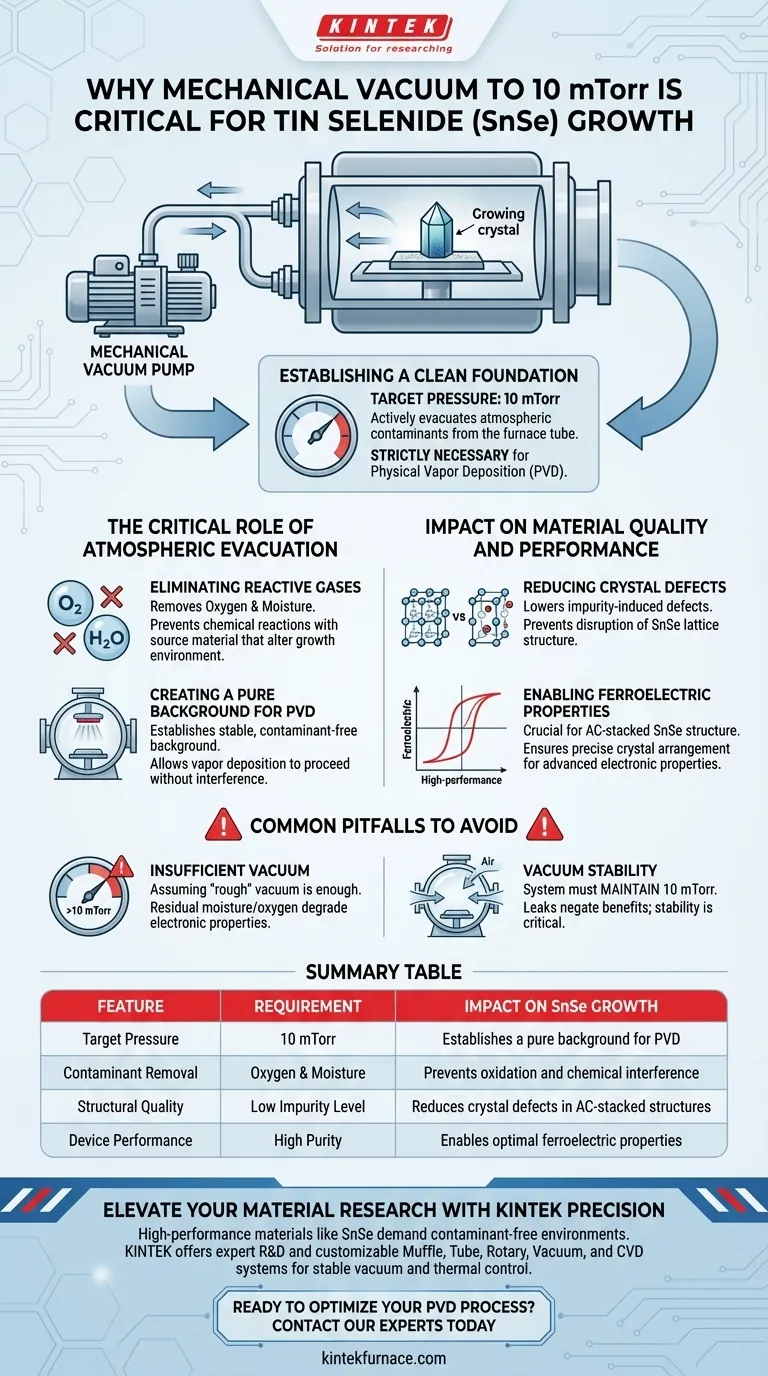

Establishing a low-vacuum environment creates a clean foundation for growth. By using a mechanical vacuum pump to lower the system pressure to 10 mTorr, you actively evacuate atmospheric contaminants from the furnace tube. This step is strictly necessary to remove oxygen and moisture before the Physical Vapor Deposition (PVD) process begins.

Reaching 10 mTorr is not merely about pressure reduction; it is the critical threshold required to eliminate environmental impurities. This ensures a pure background for PVD, preventing crystal defects that would otherwise compromise the ferroelectric performance of AC-stacked Tin Selenide (SnSe).

The Critical Role of Atmospheric Evacuation

Eliminating Reactive Gases

The primary function of the mechanical pump in this context is the removal of atmospheric components. specifically oxygen and moisture.

If these elements remain in the furnace tube, they can react chemically with the source material during heating. This reaction fundamentally alters the composition of the growth environment.

Creating a Pure Background for PVD

Physical Vapor Deposition (PVD) requires a stable and contaminant-free background to function correctly.

By achieving a pressure of 10 mTorr, you establish a pure background that allows the vapor deposition to proceed without interference. This isolation is the first step in ensuring the material grows exactly as intended.

Impact on Material Quality and Performance

Reducing Crystal Defects

The presence of foreign particles or gases during growth leads to impurity-induced crystal defects.

These defects disrupt the lattice structure of the Tin Selenide. Utilizing the vacuum pump to clear the chamber significantly lowers the likelihood of these structural imperfections occurring.

Enabling Ferroelectric Properties

For Tin Selenide (SnSe), specifically the AC-stacked structure, structural integrity is directly linked to performance.

High-performance ferroelectric behavior relies on a precise crystal arrangement. Without the vacuum step to remove impurities, obtaining the high-quality structure necessary for these advanced electronic properties is impossible.

Common Pitfalls to Avoid

The Risk of Insufficient Vacuum

A common mistake is assuming that a "rough" vacuum is sufficient for high-performance materials.

If the pressure remains above 10 mTorr, significant residual moisture and oxygen likely remain. This residual contamination is often enough to introduce defects that degrade the final electronic properties of the SnSe.

Vacuum Stability

It is not enough to simply reach 10 mTorr; the system must maintain this environment.

Any leak or fluctuation that allows atmospheric re-entry will negate the benefits of the pump. The stability of this low-vacuum state is just as critical as achieving the pressure target itself.

Ensuring Success in SnSe Growth

If your primary focus is Structural Integrity: Ensure the mechanical pump consistently holds 10 mTorr to minimize impurity-induced defects in the crystal lattice.

If your primary focus is Device Performance: Prioritize the removal of oxygen and moisture to guarantee the ferroelectric capabilities of the AC-stacked Tin Selenide are preserved.

The vacuum step is the non-negotiable gatekeeper between a failed experiment and high-performance material synthesis.

Summary Table:

| Feature | Requirement | Impact on SnSe Growth |

|---|---|---|

| Target Pressure | 10 mTorr | Establishes a pure background for PVD |

| Contaminant Removal | Oxygen & Moisture | Prevents oxidation and chemical interference |

| Structural Quality | Low Impurity Level | Reduces crystal defects in AC-stacked structures |

| Device Performance | High Purity | Enables optimal ferroelectric properties |

Elevate Your Material Research with KINTEK Precision

High-performance materials like Tin Selenide demand an environment free of contaminants. At KINTEK, we understand that achieving a precise 10 mTorr vacuum is just the beginning of successful synthesis.

Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Our lab high-temp furnaces are fully customizable to meet your unique research needs, ensuring stable vacuum environments and precise thermal control for superior crystal growth.

Ready to optimize your PVD process? Contact our experts today to find the perfect high-temperature solution for your laboratory.

Visual Guide

References

- Liang-Yao Huang, Kung‐Hsuan Lin. Anisotropy of Second‐Harmonic Generation in SnSe Flakes with Ferroelectric Stacking. DOI: 10.1002/adpr.202500033

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- Ultra High Vacuum Stainless Steel KF ISO CF Flange Pipe Straight Pipe Tee Cross Fitting

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

People Also Ask

- Why use high-alumina (Alundum) crucibles for monazite glass-ceramic synthesis? Ensure Purity in High-Heat Research

- How does a lab vacuum pump work? Understanding the Liquid Piston Mechanism

- What role does a quartz tube reaction chamber play during the Carbon Thermal Shock (CTS) process? Essential Performance

- Why are corundum or ceramic crucibles required for high-temperature magnesium evaporation processes? Ensure Purity and Prevent Crucible Failure

- Why is a laboratory vacuum drying oven utilized for recovered carbon black? Preserve rCB Integrity and Pore Structure

- What is the purpose of a PTFE-lined autoclave in TiO2 synthesis? Unlock Precision Nano-material Growth

- Why must rare earth-based halide solid electrolytes be handled in a glove box? Protect Your Materials from Degradation

- What role does a molecular pump set play in an electric current-assisted TLP bonding system? Enhance Vacuum Purity