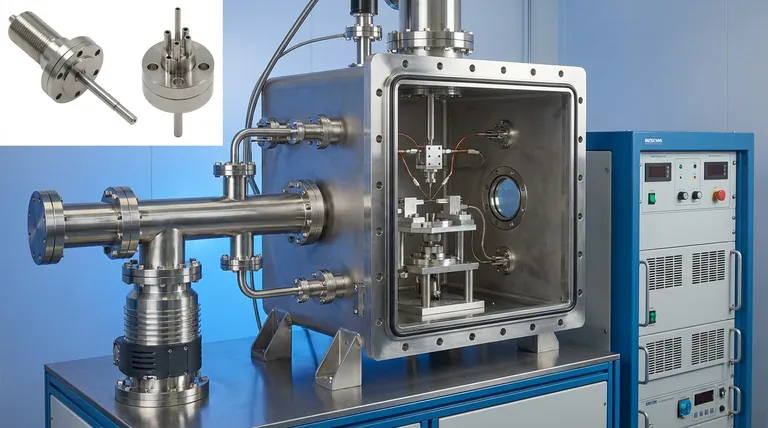

A molecular pump set functions as the primary high-vacuum acquisition system within an electric current-assisted TLP bonding setup. Its specific role is to rapidly evacuate the vacuum chamber to a precise processing level, ensuring the environment is physically prepared for the delicate bonding phase.

By aggressively lowering the chamber pressure, the molecular pump set reduces the oxygen partial pressure to negligible levels. This acts as the fundamental hardware guarantee for preventing oxidation and ensuring high-quality, contamination-free connections.

Creating the Essential Process Environment

To understand the pump's role, one must look beyond simple air removal and focus on the chemical requirements of the bonding process.

Rapid Chamber Evacuation

The molecular pump set is designed for efficiency and speed. It does not merely vent the chamber; it aggressively evacuates it to reach the "required processing vacuum level" quickly.

This rapid evacuation minimizes the downtime between loading components and starting the bonding cycle.

Controlling Oxygen Partial Pressure

The primary enemy of a successful TLP bond is oxidation. The molecular pump serves as the critical control mechanism for this variable.

By removing the atmosphere, the pump maintains an extremely low oxygen partial pressure throughout the brazing environment.

Enabling High-Quality Connections

The reference specifically highlights the role of this equipment in processing Inconel 718 capillaries.

For these materials, the vacuum environment created by the pump is the defining factor that allows for a contamination-free connection. Without this specific level of vacuum, the joint quality would be compromised by atmospheric impurities.

Critical Dependencies and Considerations

While the molecular pump provides the environment, it is important to understand the operational dependencies described in the primary reference.

The Core Hardware Guarantee

The reference describes the pump set as the "core hardware guarantee."

This implies that the pump is a single point of failure regarding joint quality. If the pump cannot achieve or maintain the target vacuum level, the integrity of the bond is effectively voided before heating begins.

The Necessity of Seal Integrity

Because the pump is tasked with achieving "extremely low" pressures, its performance is entirely dependent on the chamber's isolation.

The pump creates the vacuum, but the system relies on the chamber's ability to hold it against the atmosphere to prevent oxygen re-entry.

Ensuring High-Quality Bonding Results

To maximize the effectiveness of your TLP bonding system, consider these operational priorities:

- If your primary focus is Cycle Time: Ensure your molecular pump set is rated for rapid evacuation to minimize the wait time before the bonding phase.

- If your primary focus is Material Purity (Inconel 718): Verify that the pump is capable of achieving the specific high-vacuum threshold required to eliminate oxygen partial pressure for this alloy.

The molecular pump set is the gatekeeper of the bonding process, transforming a standard chamber into a pristine environment capable of advanced metallurgy.

Summary Table:

| Feature | Role in TLP Bonding System |

|---|---|

| Primary Function | Rapid high-vacuum acquisition and chamber evacuation |

| Oxygen Control | Reduces oxygen partial pressure to negligible levels |

| Material Integrity | Prevents oxidation, especially for sensitive alloys like Inconel 718 |

| System Importance | Serves as the core hardware guarantee for joint quality |

| Operational Goal | Minimizes cycle downtime while ensuring atmospheric purity |

Elevate Your Bonding Precision with KINTEK

Don't let oxidation compromise your metallurgy. KINTEK provides industry-leading high-vacuum solutions tailored for advanced bonding processes. Backed by expert R&D and manufacturing, we offer high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet the rigorous demands of Inconel processing and beyond.

Ready to optimize your lab's efficiency? Contact us today to discover how our specialized high-temperature furnaces and vacuum systems can deliver the pristine environment your research deserves.

References

- Yueshuai Song, Min Wan. Electric Current-Assisted TLP: Bonding of Ultrathin-Walled Inconel 718 Capillaries Temperature Field Simulation and Microstructural Analysis. DOI: 10.1088/1742-6596/2679/1/012015

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

- High Performance Vacuum Bellows for Efficient Connection and Stable Vacuum in Systems

People Also Ask

- What is the role of vacuum-sealed quartz tubes in Bi0.4Sb1.6Te3 synthesis? Ensure Purity & Precise Stoichiometry

- Why are high-purity alumina crucibles used for phosphor synthesis? Ensure Maximum Luminescence and Spectral Purity

- How does a planetary ball mill prepare precursors for furnaces? Unlock Nano-Scale Precision for High-Temp Success

- How do a brass cap and a cooling element work together? Ensuring Reliable High-Temperature Experimental Seals

- What is the temperature range for Laboratory Type Furnaces? Find Your Ideal Heat Solution

- What is the function of a honeycomb-shaped firing tray? Master Thermal Equilibrium in Ceramic Sintering

- What is the significance of quartz vacuum sealing technology in Dy4T1-xGa12 production? Ensure High-Purity Synthesis

- How does a precise substrate heating system influence fluoride thin film quality? Mastering Structural Integrity