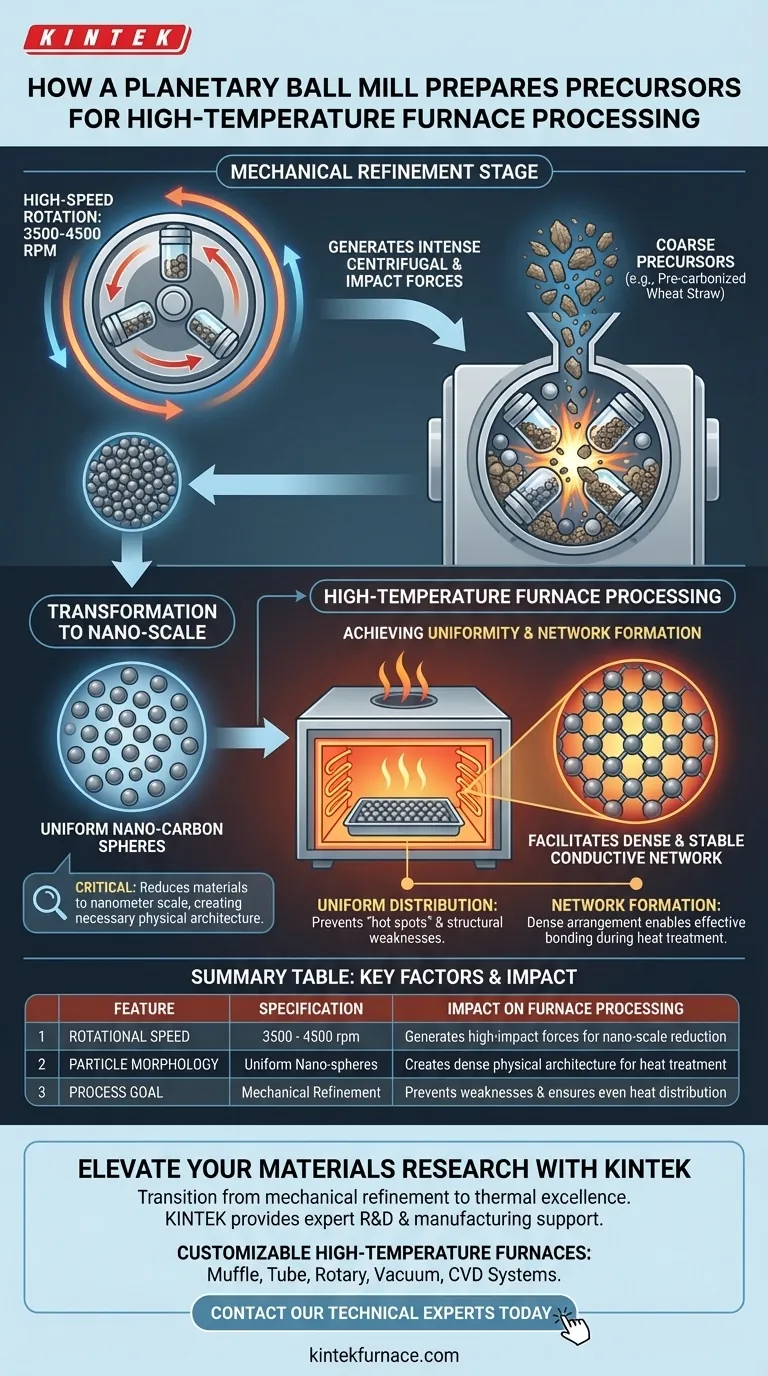

A planetary ball mill acts as a critical mechanical refinement stage by utilizing high-speed rotation to grind pre-carbonized precursors prior to thermal treatment. By operating between 3500 and 4500 rpm, the device generates intense centrifugal and impact forces that reduce materials, such as pre-carbonized wheat straw, down to the nanometer scale.

By transforming coarse particles into uniformly distributed nano-spheres, the planetary ball mill creates the physical architecture necessary for a dense and stable conductive network to form during subsequent high-temperature furnace processing.

The Mechanics of Precursor Refinement

Generating High-Impact Forces

The planetary ball mill does not simply mix materials; it subjects them to extreme kinetic energy.

Through rotation speeds of 3500 to 4500 rpm, the device creates powerful centrifugal forces. These forces drive grinding media to impact the precursor material with high frequency and intensity.

Reducing to the Nanoscale

The primary objective of this mechanical stress is significant particle size reduction.

In the context of pre-carbonized wheat straw, the milling process breaks down the bulk material into nano carbon spheres. This transformation from micro-scale to nano-scale is essential for the material's final properties.

Preparing for Thermal Processing

Achieving Uniform Distribution

High-temperature processing requires a consistent starting material to ensure even heat distribution and reaction.

The ball mill ensures that the nano-sized particles are uniformly distributed throughout the mixture. This homogeneity prevents "hot spots" or structural weaknesses during the furnace phase.

Facilitating Network Formation

The physical state of the precursor dictates the success of the final conductive network.

By refining the precursor into a dense arrangement of nano-spheres, the mill allows the material to bond effectively during heat treatment. This results in a dense and stable conductive network that would be impossible to achieve with coarser, irregular particles.

Critical Considerations and Trade-offs

The Necessity of RPM Precision

While high speed is necessary, the specific range of 3500–4500 rpm is calculated, not arbitrary.

Falling below this range may fail to generate the impact force required to reach the nanometer scale. Conversely, deviating significantly could alter the morphology of the spheres, compromising the stability of the conductive network.

Material Specificity

The process described is highly specific to the nature of the precursor, such as pre-carbonized wheat straw.

The milling parameters are tuned to fracture this specific carbon structure into spheres. Applying identical settings to a different material without adjustment may not yield the same uniform nano-spheres or conductive properties.

Optimizing Your Process Strategy

To ensure your high-temperature processing yields the best results, you must verify the output of your milling stage.

- If your primary focus is Conductivity: Ensure your milling duration and RPM are sufficient to achieve a fully uniform distribution of particles, as clumping will break the conductive path.

- If your primary focus is Structural Density: Verify that the precursor has been reduced to true nano-scale spheres, as larger particles will result in a porous, unstable final product.

The planetary ball mill is not just a grinder; it is the architect of the material's microscopic skeleton.

Summary Table:

| Feature | Specification/Detail | Impact on Furnace Processing |

|---|---|---|

| Rotational Speed | 3500 - 4500 rpm | Generates high-impact forces for nano-scale reduction |

| Particle Morphology | Uniform Nano-spheres | Creates dense physical architecture for heat treatment |

| Material Output | Nanometer-scale carbon | Enables formation of stable conductive networks |

| Process Goal | Mechanical Refinement | Prevents structural weaknesses & ensures even heat distribution |

Elevate Your Materials Research with KINTEK

Transitioning from mechanical refinement to thermal excellence requires precision at every step. KINTEK provides the expert R&D and manufacturing support you need to bridge the gap between precursor preparation and final synthesis.

Whether you require Muffle, Tube, Rotary, Vacuum, or CVD systems, our lab high-temperature furnaces are fully customizable to handle your nano-scale precursors with unmatched thermal uniformity. Don't let inconsistent heat compromise your conductive networks—partner with KINTEK for solutions tailored to your unique research needs.

Contact Our Technical Experts Today

Visual Guide

References

- Junchao Ren, Qingfa Zhang. All‐Biomass Nanocomposite Films via Facile and Sustainable Design Procedure for Thermal Management and Electromagnetic Interference Shielding. DOI: 10.1002/advs.202510372

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

People Also Ask

- What is the function of graphite molds in the Spark Plasma Sintering (SPS) of high-entropy alloys?

- Why is a vacuum suction system required during the exhaust stage of rice straw-based charcoal carbonization?

- What are the functions of silicon nitride ceramic sample holders? Precision for High-Temperature Levitation

- Why is zirconia grinding media preferred for NN-10ST ceramic powders? Ensure Purity & Dielectric Performance

- Why is a high-performance vacuum pumping system required for DLC coatings? Achieve 3.0 x 10^-5 Pa Purity

- What is the importance of using external thermometers for lead bath monitoring? Ensure Precision in Chemical Refining

- What necessary conditions does a vacuum chamber provide for vapor deposition? Achieve High-Purity Nanofluid Synthesis

- What is the function of ceramic alumina furnace tubes for Ti–Nb–Si alloys? Key Roles in Sintering & Purity