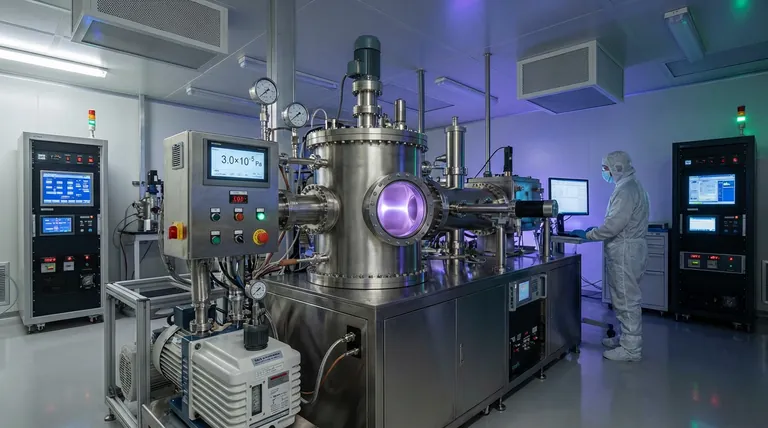

High-performance vacuum pumping is essential to create a chemically pure environment prior to the deposition of Diamond-Like Carbon (DLC) coatings. By reducing the base pressure to a critical threshold of 3.0 x 10^-5 Pa, the system maximizes the removal of residual air, moisture, and impurity gases, which ensures the stability of the plasma discharge and prevents active carbon atoms from reacting with contaminants.

Core Takeaway Achieving a high-performance vacuum is not merely about lowering pressure; it is about creating a "clean canvas" for the plasma. Removing impurities at the molecular level is the only way to guarantee that the active carbon atoms form the correct chemical bonds required for high-quality, pure DLC coatings.

The Imperative of Contaminant Removal

Eliminating the "Invisible" Barrier

Before deposition begins, the vacuum chamber is filled with atmospheric contaminants, primarily air molecules and moisture.

A high-performance pumping system is required to evacuate these elements aggressively. Without this step, these invisible impurities remain suspended in the chamber and on the substrate surface.

The Critical Pressure Threshold

The industry standard for a high-quality "base pressure" in this context is 3.0 x 10^-5 Pa.

Reaching this specific level of vacuum is the operational metric that signals the environment is sufficiently free of residual gases to proceed with deposition safely.

Preserving Chemical Integrity

Preventing Unwanted Reactions

The deposition process involves generating highly active carbon atoms.

If residual gases (like oxygen or nitrogen) are present, these active carbon atoms will react with the gas molecules rather than depositing onto the substrate. This reaction alters the chemical composition, introducing impurities that degrade the specific properties of the DLC coating.

Ensuring Plasma Stability

DLC deposition relies on a stable plasma discharge to transport material to the substrate.

Residual impurities in the vacuum chamber can cause fluctuations or instabilities in this plasma. A high-performance vacuum ensures a consistent discharge, which leads to a uniform and predictable coating structure.

Understanding the Trade-offs

Process Time vs. Coating Purity

Achieving a base pressure of 3.0 x 10^-5 Pa requires a longer "pump-down" time before the actual coating process can begin.

Operators must balance the need for extreme purity against manufacturing cycle times. Rushing this step increases throughput but inevitably risks the integrity of the coating composition.

Equipment Complexity and Cost

High-performance pumping systems capable of reaching ultra-high vacuum ranges are complex and expensive to maintain.

While they ensure superior coating quality, they represent a significant capital investment and higher operational costs compared to standard vacuum systems used for less sensitive applications.

Making the Right Choice for Your Goal

To maximize the performance of your DLC coatings, you must align your vacuum protocol with your quality requirements.

- If your primary focus is Coating Purity and Hardness: Prioritize reaching the full 3.0 x 10^-5 Pa base pressure to eliminate all potential chemical reactants.

- If your primary focus is Process Efficiency: Analyze the minimum vacuum level required for stable plasma, but acknowledge that any pressure above the benchmark introduces a risk of chemical impurities.

Ultimately, the quality of a DLC coating is defined before the deposition even starts—by the emptiness of the chamber.

Summary Table:

| Feature | Requirement for DLC | Impact on Coating Quality |

|---|---|---|

| Base Pressure | 3.0 x 10^-5 Pa | Minimizes residual air/moisture contamination |

| Plasma Stability | High-performance vacuum | Ensures uniform discharge and predictable structure |

| Chemical Purity | Removal of O2/N2 gases | Prevents active carbon from forming weak bonds |

| Substrate State | Molecularly clean surface | Enhances adhesion and coating hardness |

Elevate Your Thin Film Quality with KINTEK Precision

Don't let residual impurities compromise your Diamond-Like Carbon coatings. Achieving the critical 3.0 x 10^-5 Pa threshold requires specialized equipment designed for reliability and precision.

Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum, CVD, and specialized high-temperature furnace systems, all fully customizable to meet your unique lab or production requirements. Whether you are focusing on maximum coating hardness or process efficiency, our team provides the technical expertise to optimize your vacuum environment.

Ready to achieve superior coating purity? Contact us today to find your custom solution.

References

- Mohammadamin Sadeghi, Fábio Ferreira. Influence of 1-Ethyl-3-methylimidazolium Diethylphosphate Ionic Liquid on the Performance of Eu- and Gd-Doped Diamond-like Carbon Coatings. DOI: 10.3390/lubricants12010018

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why is the use of high-vacuum pump groups critical for photothermal catalytic chamber pre-treatment?

- What are the primary functions of multilayer fixtures within a lithium battery vacuum oven? Optimize Your Drying Process

- What role does a high-precision lab stirring device play in KR experiments? Optimizing Desulfurization Simulation

- What is the primary purpose of a vacuum pump in photocatalytic CO2 reduction? Ensure Pure Environments for Accurate Data

- What is the advantage of the circulating water multifunctional vacuum pump being one machine for multiple purposes? Streamline Lab Work Efficiently

- How do a precision hydraulic press and high-strength stainless steel molds facilitate boron carbide green body forming?

- Why are vacuum filtration devices and specific cellulose filter papers used in hydrothermal synthesis recovery?

- How does a laboratory vacuum pump system contribute to the preparation process of TixNbMoTaW refractory alloys?