High-vacuum pump groups are essential for establishing a baseline of chemical purity within sealed quartz reaction chambers. By thoroughly evacuating residual air and facilitating argon gas purging, these systems ensure the reaction environment is free from environmental contaminants before the experiment begins.

The reliability of photothermal catalytic data hinges on eliminating uncontrolled variables. High-vacuum pumps remove residual impurities, ensuring that experimental outcomes regarding yield and selectivity are the result of precise reactant ratios rather than atmospheric interference.

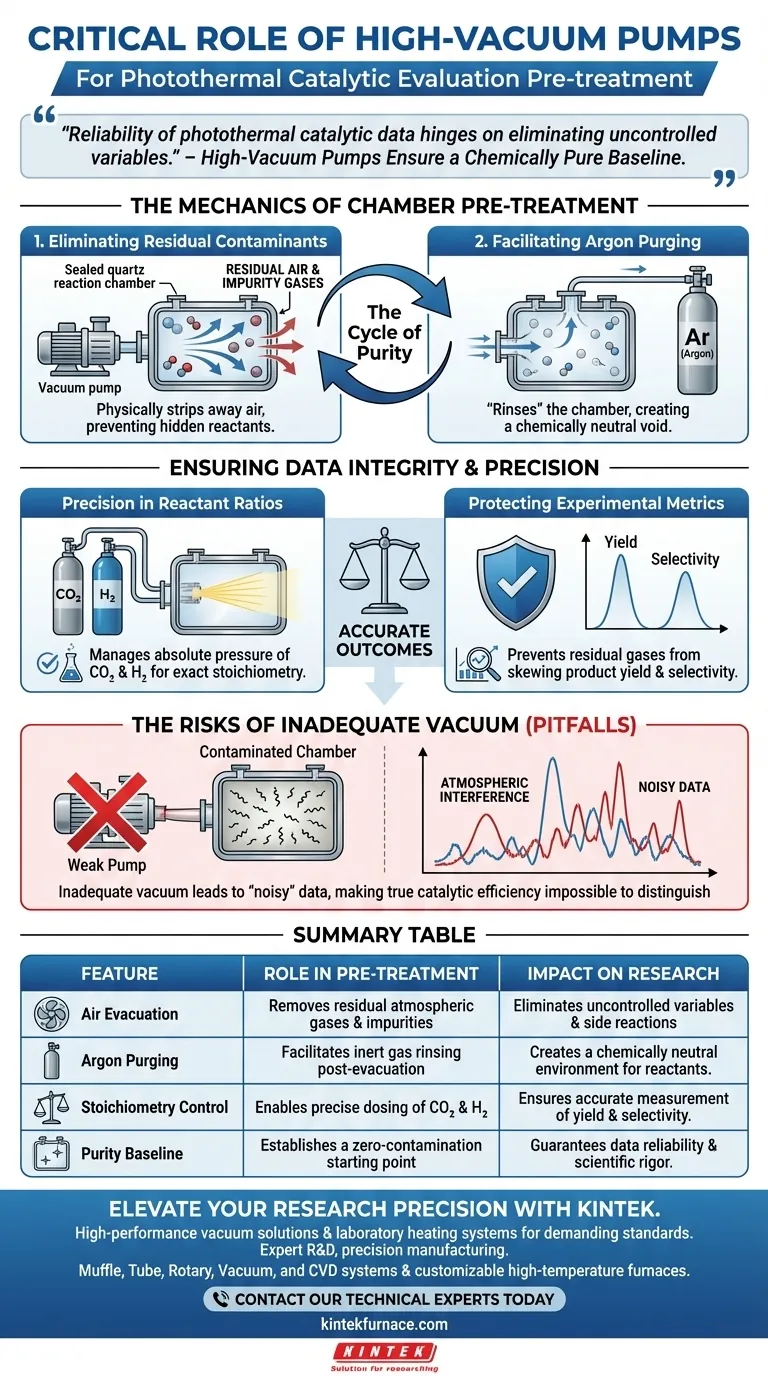

The Mechanics of Chamber Pre-treatment

Eliminating Residual Contaminants

You cannot obtain accurate data if your reaction starts with unknown variables. The primary function of the high-vacuum pump group is to evacuate the sealed quartz reaction chamber.

This process physically strips away residual air and impurity gases that are naturally present in the system. Without this step, these impurities would remain as hidden reactants.

Facilitating Argon Purging

Evacuation is rarely a standalone step; it prepares the stage for inert environments. The pump group allows for effective argon gas purging following evacuation.

This cycle ensures that the chamber is not only empty of air but effectively "rinsed" with inert gas. This creates a chemically neutral void ready for the introduction of active reactants.

Ensuring Data Integrity and Precision

Precision in Reactant Ratios

Photothermal catalysis relies on exact stoichiometry. Once the chamber is cleared of background noise, reactants such as carbon dioxide ($CO_2$) and hydrogen ($H_2$) are introduced.

Because the vacuum process has removed the air, the pressure and concentration of these gases can be managed with absolute control. This ensures the reactant ratios are precise and deliberate.

Protecting Experimental Metrics

The ultimate goal is to validate the catalyst's performance. If residual gases are present, they can skew critical data points, specifically product yield and selectivity.

High-vacuum pre-treatment acts as a firewall against this atmospheric interference. It guarantees that the results observed are due to the photothermal reaction alone, not side reactions caused by impurities.

The Risks of Inadequate Vacuum (Common Pitfalls)

The "Atmospheric Interference" Trap

The most significant trade-off in this process is the operational requirement for rigorous preparation versus the risk of compromised data.

If the vacuum stage is rushed or the pump group is insufficient, residual air will remain. This results in "noisy" data where it becomes impossible to distinguish true catalytic efficiency from the effects of contamination.

Ensuring Reliable Catalytic Evaluations

To maximize the validity of your photothermal catalytic experiments, view the vacuum system as a calibration tool for your chemical environment.

- If your primary focus is Data Accuracy: Prioritize high-vacuum capability to ensure complete removal of residual air, preventing false readings in product yield.

- If your primary focus is Process Control: Use the pump group to establish a precise baseline, allowing for exact control over the ratios of carbon dioxide and hydrogen.

The high-vacuum pump group is the gatekeeper of scientific rigor, transforming a variable-filled environment into a controlled laboratory standard.

Summary Table:

| Feature | Role in Pre-treatment | Impact on Research |

|---|---|---|

| Air Evacuation | Removes residual atmospheric gases and impurities | Eliminates uncontrolled variables and side reactions |

| Argon Purging | Facilitates inert gas rinsing post-evacuation | Creates a chemically neutral environment for reactants |

| Stoichiometry Control | Enables precise dosing of $CO_2$ and $H_2$ | Ensures accurate measurement of yield and selectivity |

| Purity Baseline | Establishes a zero-contamination starting point | Guarantees data reliability and scientific rigor |

Elevate Your Research Precision with KINTEK

Don't let atmospheric interference compromise your photothermal catalytic data. KINTEK provides high-performance vacuum solutions and laboratory heating systems engineered for the most demanding scientific standards.

Backed by expert R&D and precision manufacturing, we offer a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems. Whether you need standard lab equipment or a fully customizable high-temperature furnace tailored to your unique reaction chamber requirements, KINTEK delivers the reliability your research deserves.

Ready to optimize your experimental environment? Contact our technical experts today to find the perfect vacuum or furnace solution for your laboratory.

Visual Guide

References

- Jinglin Li, Baowen Zhou. Photo-thermal synergistic CO <sub>2</sub> hydrogenation towards CO over PtRh bimetal-decorated GaN nanowires/Si. DOI: 10.1039/d4sc01530d

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Ultra High Vacuum Stainless Steel KF ISO CF Flange Pipe Straight Pipe Tee Cross Fitting

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the secondary functions of high-purity graphite molds? Unlocking Advanced Sintering Capabilities

- What are the requirements for sealed quartz tubes for CVT? Ensure High Purity & Integrity for NiI2 and MnPS3 Growth

- What is the role of vacuum-sealed quartz tubes in Bi0.4Sb1.6Te3 synthesis? Ensure Purity & Precise Stoichiometry

- Why is a high-performance vacuum pumping system required for DLC coatings? Achieve 3.0 x 10^-5 Pa Purity

- What are the advantages of using a quartz glass reactor? Superior Visibility & Purity in Molten Salt Experiments

- Why are high-purity alumina grinding balls used for Al2O3/TiC milling? Master Chemical Consistency

- How does a heating stage contribute to the quality of multi-material 3D printing? Optimize Precision and Stability

- What role do quartz tubes and vacuum sealing play in synthesis? Master High-Reactivity Compounds like U0.92Mn3Si2C