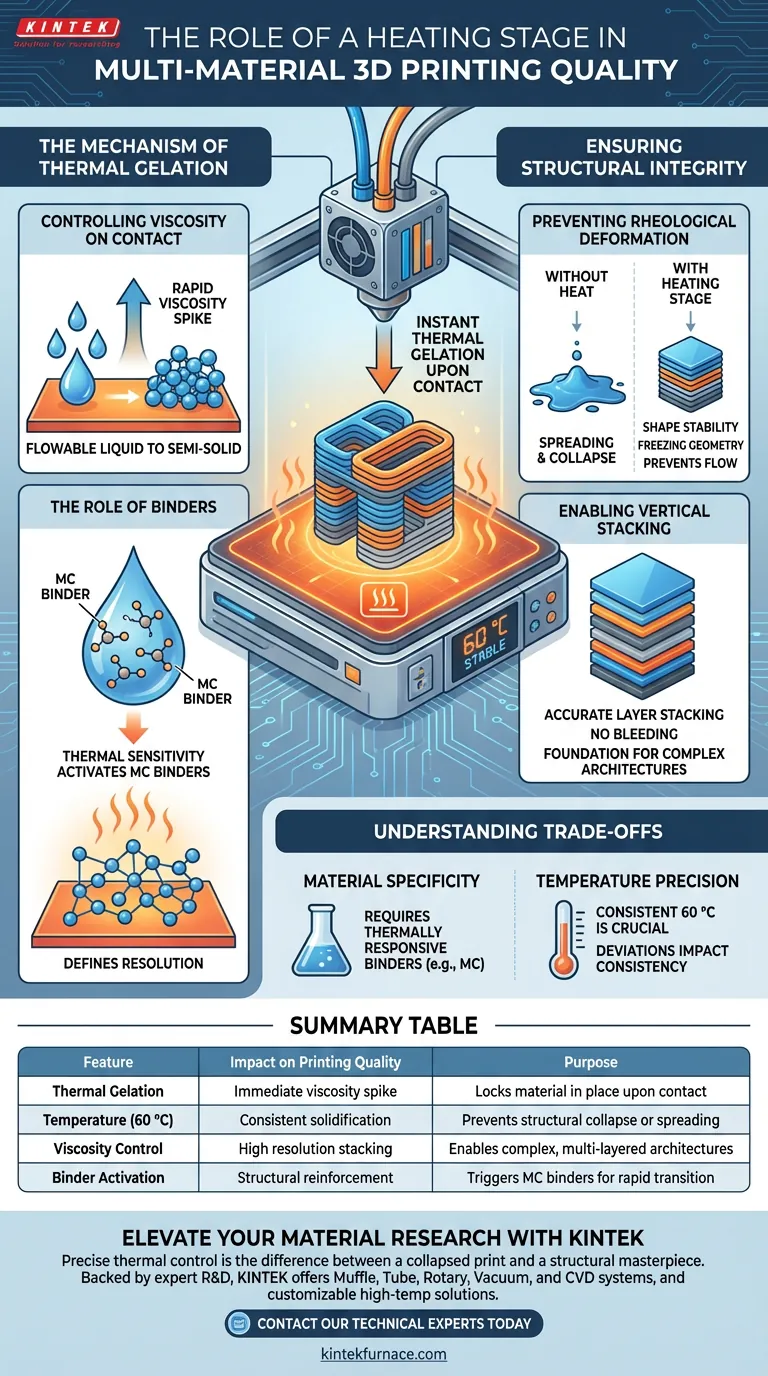

A heating stage acts as a critical stabilizer during the printing process. By maintaining a precise substrate temperature—specifically around 60 °C—it triggers an immediate physical change in inks containing methylcellulose (MC) binders. This rapid "thermal gelation" causes the ink's viscosity to spike the moment it touches the build plate, locking the material in place.

The heating stage is not merely for temperature regulation; it is a mechanism for instantaneous structural reinforcement. By inducing thermal gelation upon contact, it prevents material spreading and enables the accurate stacking necessary for complex 3D structures.

The Mechanism of Thermal Gelation

Controlling Viscosity on Contact

The primary function of the heating stage is to manipulate the physical state of the ink in real-time.

When the liquid ink contacts the heated substrate, the thermal energy acts as a catalyst. This causes the viscosity of the material to rise rapidly, transitioning it from a flowable liquid to a semi-solid state almost instantly.

The Role of Binders

This process relies heavily on specific chemical binders within the ink, such as methylcellulose (MC).

These binders are sensitive to thermal changes. The heating stage provides the exact environmental trigger required to activate these binders, initiating the gelation process that defines the print's resolution.

Ensuring Structural Integrity

Preventing Rheological Deformation

Without immediate solidification, liquid inks are susceptible to gravity and surface tension, leading to spreading or structural collapse.

The heating stage ensures shape stability by "freezing" the filament geometry in place. This prevents rheological deformation, where the material flows unwantedly before it sets.

Enabling Vertical Stacking

High-quality multi-material printing requires the ability to layer different materials without them bleeding into one another or collapsing.

By stabilizing each layer immediately, the heating stage allows for the accurate stacking of filaments. This stability is the foundation for building complex, multi-layered 3D architectures with high fidelity.

Understanding the Trade-offs

Material Specificity

It is important to note that this technique is highly material-dependent.

The benefits described here specifically apply to inks formulated with binders like methylcellulose that exhibit thermal gelation. Materials that do not respond to heat in this manner will not benefit from this specific stabilization method.

Temperature Precision

The success of this method relies on maintaining a consistent temperature (approximately 60 °C).

Deviations in substrate temperature can lead to inconsistent gelation. Too cool, and the structure may collapse; too hot, and the material behavior may become unpredictable or dry too quickly.

Making the Right Choice for Your Project

To leverage a heating stage effectively, you must align your hardware capabilities with your material science.

- If your primary focus is complex geometries: Ensure your ink formulation contains thermally responsive binders (like MC) to utilize the heating stage for immediate stabilization.

- If your primary focus is material consistency: Calibrate your heating stage to maintain 60 °C precisely, as fluctuations will directly impact the viscosity and stacking accuracy of your print.

Mastering the thermal environment of the substrate is the key to transforming liquid ink into a precise, self-supporting structure.

Summary Table:

| Feature | Impact on Printing Quality | Purpose |

|---|---|---|

| Thermal Gelation | Immediate viscosity spike | Locks material in place upon contact |

| Temperature (60 °C) | Consistent solidification | Prevents structural collapse or spreading |

| Viscosity Control | High resolution stacking | Enables complex, multi-layered architectures |

| Binder Activation | Structural reinforcement | Triggers MC binders for rapid transition |

Elevate Your Material Research with KINTEK

Precise thermal control is the difference between a collapsed print and a structural masterpiece. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as specialized lab high-temp solutions. Whether you are developing advanced ink formulations or complex 3D architectures, our customizable systems are designed to meet your unique research needs.

Ready to stabilize your process? Contact our technical experts today to find the perfect heating solution for your laboratory.

Visual Guide

References

- Highly Stable Low‐Temperature Phosphate Glass as a Platform for Multimaterial 3D Printing of Integrated Functional Microfluidic Devices. DOI: 10.1002/adem.202501603

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the technical advantages of using high-purity quartz tubes? Optimize Heat and Purity in Combustion Analysis

- How do B-type thermocouples contribute to temperature control in CaO-Al2O3-VOx slag processing? Achieve ±2 °C Precision

- Why are high-purity alumina crucibles preferred? Secure Unmatched Purity and Data Integrity in Lab Synthesis

- What are the specific functions of a magnetic stirrer and a condenser reflux apparatus in the synthesis of KCC-1? Expert Insights

- How does insulation affect laboratory furnace design? Optimize Thermal Performance and Safety

- Why are high-purity MgO crucibles used for PbO oxidation? Essential Chemical Inertness for Master Slags

- What functions do high-purity sulfur powder and ceramic boats serve in TB-MoS2 prep? Precision in 2D Material Synthesis

- What is the specific significance of using high-purity corundum crucibles in oxidation weight gain experiments?