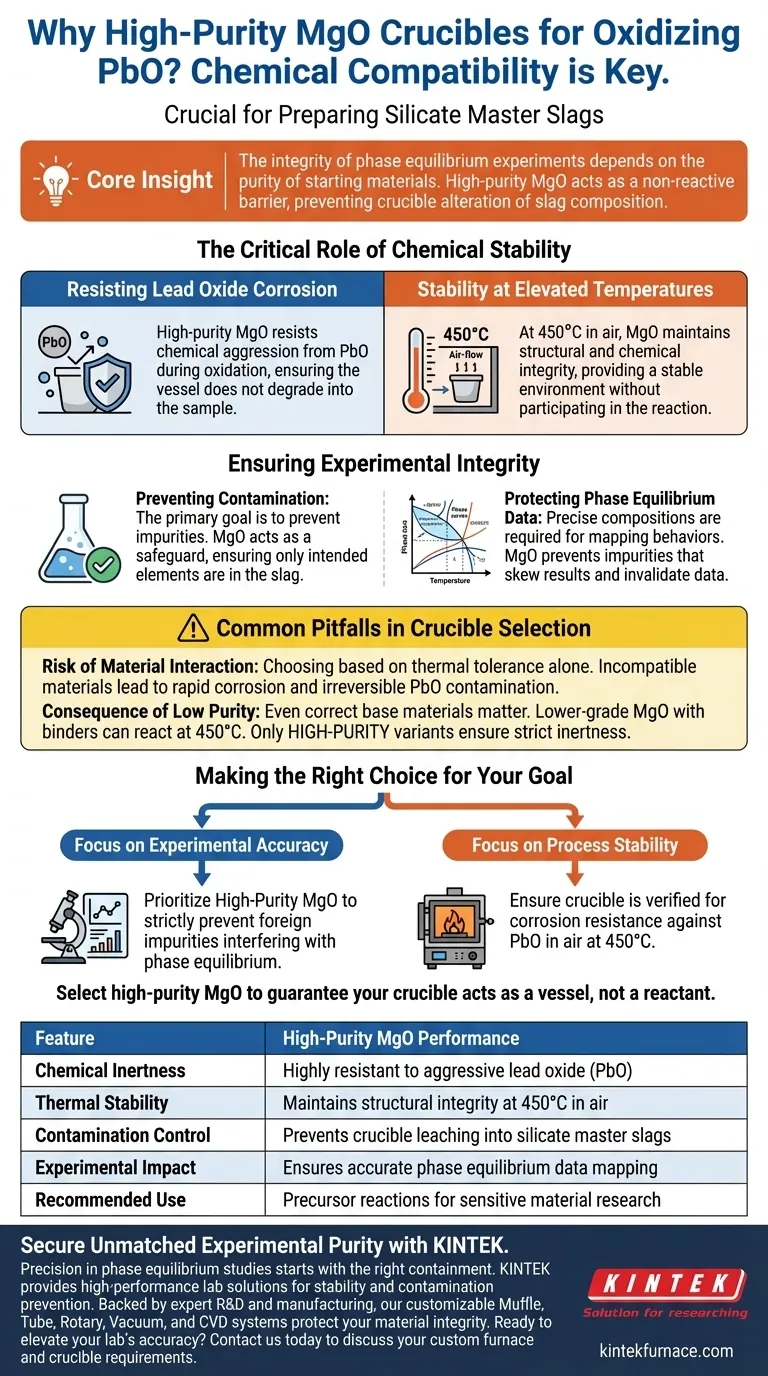

Chemical compatibility is the deciding factor when selecting crucibles for this specific oxidation process. High-purity magnesium oxide (MgO) crucibles are used because they are chemically inert to lead oxide (PbO) in a 450°C air environment, effectively preventing corrosion and ensuring the final silicate master slag remains free of contaminants.

Core Insight: The integrity of phase equilibrium experiments depends entirely on the purity of the starting materials. High-purity MgO is utilized not just for containment, but to act as a non-reactive barrier that prevents the crucible itself from altering the chemical composition of the slag.

The Critical Role of Chemical Stability

Resisting Lead Oxide Corrosion

Lead oxide (PbO) can be chemically aggressive towards many containment materials, particularly during oxidation processes.

High-purity MgO provides excellent chemical compatibility in this context. It effectively resists corrosion caused by contact with lead oxides, ensuring the vessel does not degrade into the sample.

Stability at Elevated Temperatures

The oxidation of PbO for silicate master slags typically occurs in an air environment at 450°C.

Under these specific thermal and atmospheric conditions, magnesium oxide maintains its structural and chemical integrity. It provides a stable environment for the reaction without participating in it.

Ensuring Experimental Integrity

Preventing Contamination

The primary goal of using high-purity MgO is to prevent the introduction of impurities into the master slag.

If a crucible reacts with the melt, elements from the crucible wall leach into the sample. MgO acts as a safeguard, ensuring that the only elements present in the slag are those intended by the researcher.

Protecting Phase Equilibrium Data

The preparation of these slags is often a precursor to phase equilibrium experiments.

These experiments require precise chemical compositions to map material behaviors accurately. Any impurities introduced by a corroding crucible would skew the results, rendering subsequent experimental data invalid.

Common Pitfalls in Crucible Selection

The Risk of Material Interaction

A common oversight in slag preparation is selecting a crucible based solely on thermal tolerance rather than chemical inertness.

Using a crucible material that is not compatible with PbO leads to rapid corrosion. This not only destroys the crucible but irreversibly contaminates the lead oxide sample.

The Consequence of Low Purity

Even when using the correct base material, the purity level is critical.

Lower-grade MgO crucibles may contain binders or impurities that can react at 450°C. Only high-purity variants ensure the strict inertness required for sensitive phase equilibrium studies.

Making the Right Choice for Your Goal

To ensure the success of your master slag preparation, align your material selection with your experimental requirements.

- If your primary focus is experimental accuracy: Prioritize high-purity MgO to strictly prevent the introduction of foreign impurities that interfere with phase equilibrium.

- If your primary focus is process stability: Ensure the crucible material is verified for corrosion resistance specifically against lead oxides in an air environment at 450°C.

Select high-purity MgO to guarantee that your crucible acts as a vessel, not a reactant.

Summary Table:

| Feature | High-Purity MgO Performance |

|---|---|

| Chemical Inertness | Highly resistant to aggressive lead oxide (PbO) |

| Thermal Stability | Maintains structural integrity at 450°C in air |

| Contamination Control | Prevents crucible leaching into silicate master slags |

| Experimental Impact | Ensures accurate phase equilibrium data mapping |

| Recommended Use | Precursor reactions for sensitive material research |

Secure Unmatched Experimental Purity with KINTEK

Precision in phase equilibrium studies starts with the right containment. KINTEK provides the high-performance laboratory solutions required to prevent costly contamination and ensure process stability.

Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of lab high-temp equipment, including Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which are fully customizable to meet your unique chemical compatibility needs. Whether you are preparing master slags or conducting complex thermal reactions, our equipment is designed to protect your material integrity.

Ready to elevate your lab's accuracy? Contact us today to discuss your custom furnace and crucible requirements with our technical experts.

Visual Guide

References

- Georgii Khartcyzov, Evgueni Jak. Integrated Experimental and Thermodynamic Modelling Study of Phase Equilibria in the PbO-AlO1.5-SiO2 System in Air. DOI: 10.1007/s12540-024-01878-4

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Magnesium Extraction and Purification Condensing Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why is a graphite crucible used for melting Al-Mg-Si alloys? Superior Purity & Thermal Efficiency

- What function does a PTFE liner serve in NiWO4 synthesis? Ensure Purity & Prevent Corrosion in Hydrothermal Reactors

- Why are high-purity alumina crucibles preferred over quartz crucibles at 1873 K? Ensure Precision at Extreme Heat

- How does the dispersion of ruthenium precursors on alumina carriers affect thermal processing in a lab furnace?

- Why is a Pt5%Au crucible required for S53P4 bioactive glass? Ensure Purity at 1400°C

- Why is a copper getter chamber integrated into heating systems? Ensure Ultra-Pure Alloy Processing

- What is the purpose of a water-cooled condenser in a thermal vacuum mercury removal apparatus? Key for Safe Recovery

- How has the circulating water vacuum pump been received in practical use? Durable, Cost-Effective for Lab Tasks