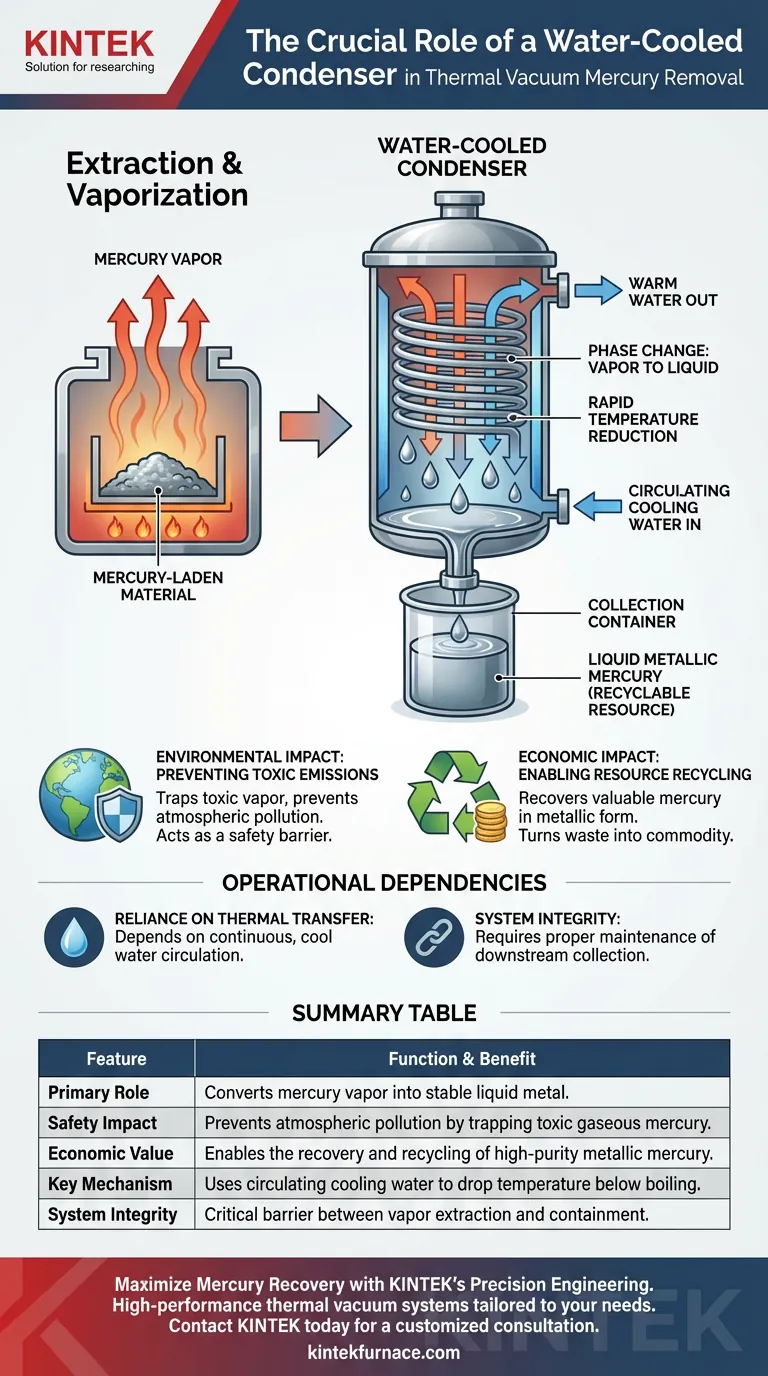

The primary function of a water-cooled condenser in a thermal vacuum mercury removal apparatus is to facilitate the safe phase change of mercury from a vapor back into a liquid state. By circulating cooling water through the system, the condenser rapidly lowers the temperature of the mercury-laden gas, converting the vapor into metallic liquid mercury that can be captured in specialized containers.

Core Takeaway: This component serves as the critical junction between extraction and containment. It transforms hazardous vapors into a stable, collectible liquid, simultaneously preventing atmospheric pollution and enabling the economic recycling of mercury resources.

The Mechanics of Recovery

Rapid Temperature Reduction

The thermal vacuum process vaporizes mercury to separate it from other materials. The condenser acts as a heat exchanger, utilizing circulating cooling water to absorb thermal energy from this vapor stream.

This cooling action must be consistent and rapid. By aggressively lowering the temperature within the gas path, the system forces the mercury vapor below its boiling point.

Phase Transition and Collection

As the temperature drops, the mercury undergoes a physical phase change, condensing from a volatile gas into liquid metallic mercury.

Once liquefied, the mercury flows into designated collection containers. This physical separation is the definitive step that removes the mercury from the process flow, isolating it for handling.

Environmental and Economic Impact

Preventing Toxic Emissions

Without a functional condenser, mercury vapor would remain in a gaseous state. This would pose a significant risk of escaping the system and contaminating the surrounding atmosphere.

The condenser acts as a safety barrier. It ensures that toxic mercury vapor is trapped and contained within the system, rather than being released as an environmental hazard.

Enabling Resource Recycling

Beyond safety, the condenser turns a waste product into a valuable commodity. By recovering the mercury in its metallic liquid form, the apparatus allows for the recycling of associated metals.

This transforms the operation from a simple waste disposal process into a resource recovery cycle, retaining the value of the materials involved.

Operational Dependencies

Reliance on Thermal Transfer

The efficiency of the mercury removal is entirely dependent on the cooling medium. Because the system relies on circulating water, any interruption in flow or rise in water temperature directly impacts recovery rates.

System Integrity

The condenser creates a specific collection point for the liquid metal. Consequently, the downstream specialized containers must be properly maintained to handle the accumulation of heavy liquid mercury.

Making the Right Choice for Your Goal

When evaluating the performance of a thermal vacuum system, the condenser is often the limiting factor for both safety and speed.

- If your primary focus is Environmental Safety: Prioritize a condenser design with redundant cooling capacity to ensure zero vapor breakthrough, preventing atmospheric release.

- If your primary focus is Resource Recovery: Ensure the cooling water circulation is optimized to maximize the condensation rate, allowing for the highest possible yield of recyclable metallic mercury.

The effectiveness of your condenser ultimately determines whether your apparatus is a containment risk or a sustainable recycling solution.

Summary Table:

| Feature | Function & Benefit |

|---|---|

| Primary Role | Converts mercury vapor into stable liquid metal through heat exchange. |

| Safety Impact | Prevents atmospheric pollution by trapping toxic gaseous mercury. |

| Economic Value | Enables the recovery and recycling of high-purity metallic mercury. |

| Key Mechanism | Uses circulating cooling water to rapidly drop temperatures below boiling point. |

| System Integrity | Serves as the critical barrier between vapor extraction and secure containment. |

Maximize Mercury Recovery with KINTEK’s Precision Engineering

Ensure the highest safety standards and resource efficiency for your laboratory or industrial processes. Backed by expert R&D and manufacturing, KINTEK offers high-performance thermal vacuum systems, including customizable Muffle, Tube, Rotary, Vacuum, and CVD furnaces tailored to your specific temperature and containment needs.

Don't compromise on environmental safety or recovery yields. Our expert team is ready to design a solution that optimizes your thermal transfer and system integrity.

Contact KINTEK today for a customized consultation

Visual Guide

References

- Bagdaulet Kenzhaliyev, Xeniya Linnik. Preliminary Removal of Mercury from Depleted Coal Sorbents by Thermal Vacuum Method with Associated Extraction of Precious Metal Composite. DOI: 10.3390/jcs8090367

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Magnesium Extraction and Purification Condensing Tube Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- Vacuum Heat Treat Sintering and Brazing Furnace

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

People Also Ask

- How does a Mass Flow Controller (MFC) regulate TCNF morphology? Achieve Precise Carbon Nanofiber Growth

- What technical considerations justify the use of high-purity alumina crucibles for microwave-assisted metal reduction?

- Which industries commonly use graphite crucible furnaces? Essential for High-Temp, High-Purity Processes

- Why is a high-purity graphite crucible preferred for (AgCu)0.999Te0.69Se0.3S0.01 preparation? Ensure Peak Purity.

- What is the maximum pressure achievable by the circulating water vacuum pump? Discover Its Vacuum Limits

- Why is a precision laboratory hydraulic press required for sulfide-based batteries? Achieve Critical Ion Conductivity

- What are the benefits of using high-purity alumina or platinum crucibles? Enhance Purity in Specialized Glass Melting

- Why is the selection of high-purity crucibles critical for niobate sintering? Ensure Precision in High-Temp Synthesis