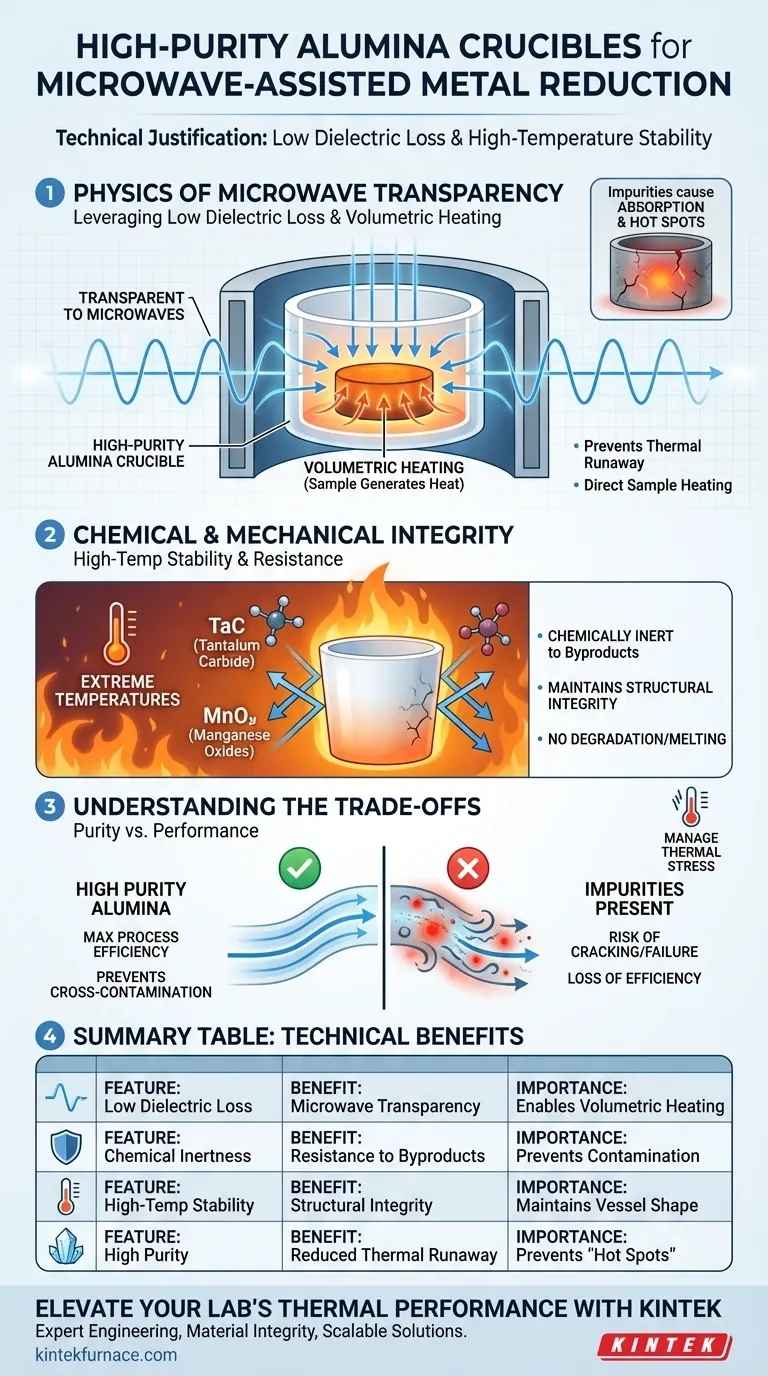

The primary technical justification for using high-purity alumina crucibles in microwave-assisted metal reduction is their combination of low dielectric loss and exceptional high-temperature chemical stability. These properties ensure that microwave energy passes through the vessel to heat the reactants directly, rather than heating the crucible itself, while simultaneously preventing the vessel from reacting with aggressive reduction products.

The critical value of high-purity alumina is its ability to act as a transparent window for microwave energy, facilitating volumetric heating of the sample while resisting contamination from byproducts like tantalum carbide or manganese oxides.

The Physics of Microwave Transparency

Leveraging Low Dielectric Loss

The fundamental requirement for a microwave vessel is low dielectric loss. High-purity alumina is nearly transparent to microwaves, meaning it does not absorb significant energy from the electromagnetic field.

Achieving Volumetric Heating

Because the crucible does not absorb the energy, the microwaves pass directly through the vessel wall to the carbon-containing sample inside.

This allows for volumetric heating, where the sample generates heat internally rather than relying on conduction from the container walls.

Preventing Thermal Runaway

If the crucible were to absorb microwave energy, it would heat up independently of the sample. High-purity alumina prevents this overheating, ensuring the temperature profile is controlled by the reaction kinetics rather than the vessel's properties.

Chemical and Mechanical Integrity

High-Temperature Stability

Metal reduction processes occur at extreme temperatures. High-purity alumina maintains its chemical stability under these rigorous conditions, ensuring the vessel does not degrade or melt during the process.

Resistance to Reduction Products

During the reduction process, aggressive byproducts such as tantalum carbide or manganese oxides are often formed.

Alumina is chemically inert to these specific compounds. This prevents the crucible from reacting with the payload, which preserves the purity of the reduced metal and extends the lifespan of the crucible.

Mechanical Strength

Beyond thermal and chemical properties, the process requires a vessel with substantial mechanical strength. Alumina provides the structural integrity necessary to contain the load without failure under process stress.

Understanding the Trade-offs: Purity vs. Performance

The Risk of Impurities

It is critical to note that these benefits rely strictly on the alumina being high purity.

If impurities are present in the ceramic matrix, the dielectric loss increases. This causes the crucible to begin absorbing microwave energy, leading to "hot spots," potential cracking, and a loss of process efficiency.

Thermal Stress Management

While alumina is strong, it is a ceramic material. The rapid volumetric heating of the sample can create temperature gradients between the hot sample and the cooler crucible wall.

Users must ensure that the mechanical strength of the chosen alumina grade is sufficient to withstand the thermal expansion stresses caused by this rapid internal heating.

Making the Right Choice for Your Goal

To maximize the effectiveness of your microwave-assisted reduction process, align your material selection with your specific technical constraints.

- If your primary focus is Process Efficiency: Prioritize the highest available purity to minimize dielectric loss, ensuring maximum energy transfer directly to the carbon-containing sample.

- If your primary focus is Sample Purity: Rely on alumina’s inertness to prevent cross-contamination, specifically when working with reactive byproducts like tantalum carbide.

High-purity alumina is not just a container; it is an active component of the thermal system that defines the success of microwave-assisted reduction.

Summary Table:

| Feature | Technical Benefit | Importance in Microwave Reduction |

|---|---|---|

| Low Dielectric Loss | Microwave Transparency | Enables volumetric heating by passing energy directly to the sample. |

| Chemical Inertness | Resistance to Byproducts | Prevents contamination from aggressive products like tantalum carbide. |

| High-Temp Stability | Structural Integrity | Maintains vessel shape and performance at extreme process temperatures. |

| High Purity | Reduced Thermal Runaway | Prevents "hot spots" and cracking by minimizing unintended energy absorption. |

Elevate Your Lab's Thermal Performance with KINTEK

Precision in microwave-assisted reduction starts with the right equipment. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, along with high-performance laboratory ceramics. Our high-purity solutions are designed to withstand aggressive reduction products while ensuring maximum energy efficiency.

Why choose KINTEK?

- Expert Engineering: Customizable high-temperature furnaces tailored to your unique research needs.

- Material Integrity: High-purity alumina components that prevent contamination and thermal runaway.

- Scalable Solutions: From benchtop lab furnaces to complex CVD systems.

Ready to optimize your metal reduction process? Contact KINTEK today for a consultation and let our experts design the perfect thermal solution for your laboratory.

Visual Guide

References

- Ansan Pokharel, Terence Musho. Microwave-assisted recycling of tantalum and manganese from end-of-life tantalum capacitors. DOI: 10.1038/s41598-025-96574-7

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Magnesium Extraction and Purification Condensing Tube Furnace

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Vacuum Induction Melting Furnace

People Also Ask

- What processes can a circulating water vacuum pump provide negative pressure conditions for? Essential Lab Techniques Explained

- Why is the precision of a Mass Flow Controller (MFC) critical for ethanol vapor detection? Master Accurate Gas Mixing

- Why is a high-purity alumina corundum crucible preferred for melting? Achieve High-Precision Research Integrity

- What role does a covered alumina or aluminum alloy crucible play in g-C3N4 synthesis? Maximize Yield and Quality

- Why is a high-purity graphite crucible typically chosen for the high-temperature vacuum carbothermic reduction of magnesium oxide?

- What are tube furnace tubes made of? Select the Right Material for Your Process

- What are the technical advantages of using a quartz tube as a reaction chamber? Optimize g-C3N4 Thin Film CVD Processes

- How does a laboratory drying oven contribute to maintaining material activity? Preserve Catalyst Performance Easily