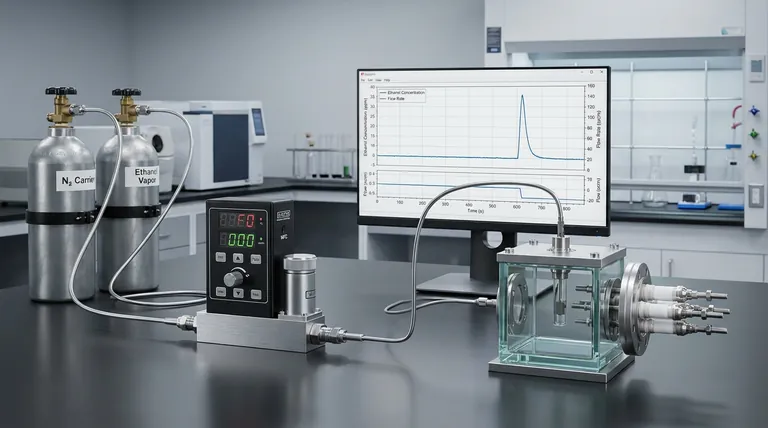

The precision of a Mass Flow Controller (MFC) is the foundation of reliable sensor data. In ethanol vapor detection experiments, the MFC acts as the critical regulator for carrier gases (like nitrogen) and dilution gases. Its primary function is to maintain exact flow rates, ensuring that the concentration of ethanol vapor in the test environment is accurate, stable, and reproducible.

Core Insight: An MFC provides real-time proportional control, allowing you to adjust ethanol vapor concentrations within precise flow ratios (such as 0.1 to 0.4). This accuracy is non-negotiable for verifying a sensor's linear response, sensitivity, and dynamic recovery capabilities.

Regulating the Test Environment

Precise Gas Mixing

In vapor detection, the "sample" is a mixture of gases. An MFC strictly regulates the flow of the carrier gas (often nitrogen) and the dilution gas.

By controlling these inputs independently, the MFC creates a stable, homogenous environment. This prevents fluctuations that could be mistaken for changes in sensor activity.

Targeting Specific Concentrations

To characterize a sensor, you must expose it to known quantities of ethanol.

The MFC allows you to accurately adjust the concentration of ethanol vapor by manipulating flow ratios. As noted in standard experimental setups, maintaining ratios between 0.1 and 0.4 is essential for creating a controlled testing range.

Verifying Sensor Performance

Establishing Linear Response

A reliable sensor must show a linear relationship between the actual concentration of ethanol and the signal it produces.

If the MFC cannot maintain a steady flow, the input concentration varies unpredictably. This makes it impossible to distinguish between a flaw in the sensor's linearity and a flaw in the gas delivery system.

Determining Sensitivity limits

Sensitivity testing requires exposing the sensor to minute, incremental changes in vapor concentration.

Real-time proportional control ensures that these increments are deliberate and exact. This precision allows you to confidently define the sensor's lower limit of detection.

Measuring Dynamic Recovery

Recovery time—how quickly a sensor returns to baseline after exposure—is a key performance metric.

An MFC allows for rapid, controlled switching between the ethanol mixture and a purge gas. This sharp transition is necessary to accurately measure the sensor's response and recovery times under dynamic conditions.

Understanding the Risks of Inaccuracy

The "False Signal" Problem

The most significant risk in vapor detection is conflating flow rate variance with concentration variance.

If your flow controller lacks precision, a momentary surge in gas flow can alter the sensor's thermal or chemical environment. The sensor may register this as a spike in ethanol concentration, leading to false positives or incorrect sensitivity data.

Making the Right Choice for Your Goal

If your primary focus is Sensor Calibration: Ensure your MFC offers high stability at low flow rates to maintain the strict 0.1 to 0.4 flow ratios required for verifying linearity.

If your primary focus is Response Time Testing: Prioritize an MFC with rapid response times to facilitate immediate switching between carrier and target gases for accurate recovery analysis.

Precision in flow control is the only way to ensure your sensor data reflects physical reality rather than experimental noise.

Summary Table:

| Feature | Impact on Ethanol Detection | Critical Benefit |

|---|---|---|

| Flow Ratio Control | Maintains precise 0.1 to 0.4 ratios | Ensures accurate vapor concentration |

| Real-time Proportional Control | Adjusts gas mixing dynamically | Verifies sensor linearity & sensitivity |

| Rapid Gas Switching | Immediate transition to purge gas | Accurate measurement of recovery times |

| High Stability | Prevents flow rate fluctuations | Eliminates false signals and noise |

Elevate Your Sensor Research with KINTEK Precision

Don't let experimental noise compromise your results. KINTEK provides high-precision gas handling solutions designed for the most demanding vapor detection experiments. Backed by expert R&D and manufacturing, we offer customizable systems to meet your unique laboratory needs.

Our range includes:

- Precision Mass Flow Controllers (MFCs)

- Customizable CVD and Vacuum systems

- Muffle, Tube, and Rotary high-temp furnaces

Ensure your data reflects reality. Contact KINTEK today to discuss how our customizable laboratory equipment can optimize your ethanol detection research!

References

- Birhanu Alemayehu, Guru Subramanyam. Indium-Doped SnO2 Based Surface Acoustic Wave Gas Sensor with Ba0.6Sr0.4TiO3 Film. DOI: 10.3390/cryst14040366

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Ultra High Vacuum CF Observation Window Flange with High Borosilicate Glass Sight Glass

- Ultra-High Vacuum Flange Aviation Plug Glass Sintered Airtight Circular Connector for KF ISO CF

People Also Ask

- Why is a gas mixing system essential for syngas annealing in copper powder production? Ensure Precise Embrittlement

- What role does a laboratory hydraulic press play in manufacturing nickel composites? Achieving Maximum Density

- What is the function of a laboratory pellet press in PCM preparation? Optimize Building Energy Storage Materials

- Why use high-precision gas flow control for argon in oil migration simulations? Achieve Re=215 Accuracy

- What is the purpose of an ultrasonic cleaner in NiMo@Cx catalyst prep? Achieve Uniform Slurry & High-Porosity Coatings

- What is the function of a rotary evaporator in the recovery of formic acid lignin? Preserve Quality & Boost Efficiency

- What role do high-purity graphite crucibles play in Boron Carbide sintering? Optimize Ceramic Purity and Density

- Why are laboratory vacuum pumps and pressure gauges essential for aluminum foams? Ensure High-Quality Sintering Results