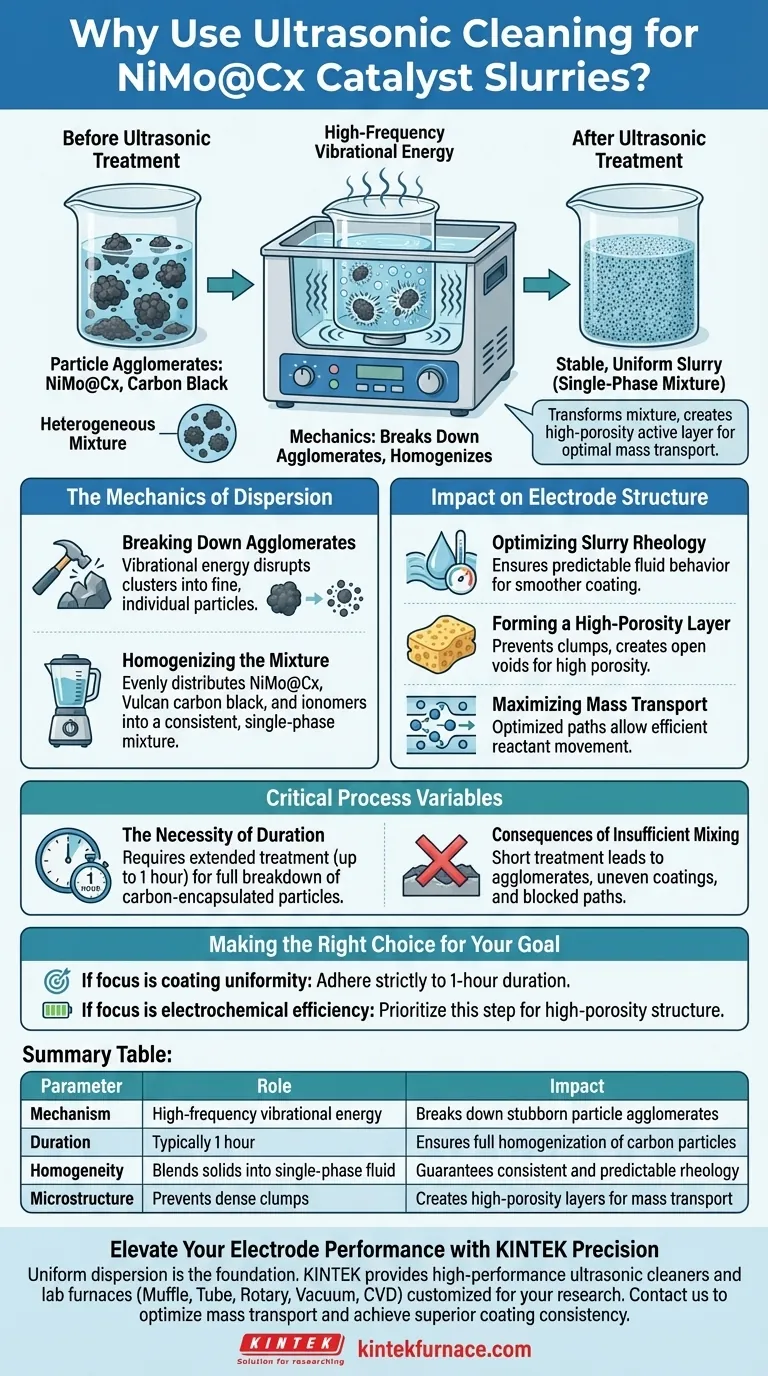

The primary purpose of using an ultrasonic cleaner is to utilize high-frequency vibrational energy to thoroughly disperse NiMo@Cx catalyst particles, Vulcan carbon black, and ionomers within a solvent mixture. This mechanical action effectively breaks down stubborn particle agglomerates, ensuring the slurry achieves the necessary consistency for uniform electrode coating.

Extended ultrasonic treatment transforms a heterogeneous mixture into a stable, uniform slurry. This step is fundamental to creating a high-porosity active layer that optimizes mass transport within the final electrochemical cell.

The Mechanics of Dispersion

Breaking Down Agglomerates

Catalyst particles and carbon supports have a natural tendency to cluster together. The ultrasonic cleaner generates vibrational energy that physically disrupts these agglomerates, separating them into finer, individual particles.

Homogenizing the Mixture

To create an effective slurry, the solid components must be evenly distributed within the isopropanol and water solvent. Ultrasonic treatment ensures that the NiMo@Cx, Vulcan carbon black, and ionomers are blended into a consistent, single-phase mixture.

Impact on Electrode Structure

Optimizing Slurry Rheology

The flow properties, or rheology, of the slurry are dictated by how well the solids are dispersed. Breaking down particles ensures the fluid behaves predictably during application, leading to a smoother coating process.

Forming a High-Porosity Layer

A uniform dispersion is required to build an active layer with high porosity. By preventing large clumps from forming, the slurry dries into a structure that maintains open voids rather than dense, blocked regions.

Maximizing Mass Transport

The physical structure of the electrode directly impacts electrochemical performance. The high porosity achieved through ultrasonic mixing creates optimized paths for mass transport, allowing reactants to move efficiently through the cell.

Critical Process Variables

The Necessity of Duration

Achieving a truly uniform dispersion is not instantaneous. The process typically requires extended treatment, often lasting up to one hour, to fully break down carbon-encapsulated particles.

Consequences of Insufficient Mixing

If the ultrasonic treatment is cut short, agglomerates will remain in the slurry. This leads to uneven coatings and blocked transport paths, significantly degrading the final performance of the electrochemical cell.

Making the Right Choice for Your Goal

To maximize the effectiveness of your electrode preparation, consider the following regarding the ultrasonication step:

- If your primary focus is coating uniformity: Adhere strictly to the one-hour treatment duration to ensure all agglomerates are eliminated before application.

- If your primary focus is electrochemical efficiency: Prioritize this step to guarantee the high-porosity structure required for optimal mass transport paths.

Proper slurry preparation is the invisible foundation of high-performance electrode fabrication.

Summary Table:

| Parameter | Role in Slurry Preparation | Impact on Performance |

|---|---|---|

| Mechanism | High-frequency vibrational energy | Breaks down stubborn particle agglomerates |

| Duration | Typically 1 hour of treatment | Ensures full homogenization of carbon particles |

| Homogeneity | Blends solids into single-phase fluid | Guarantees consistent and predictable rheology |

| Microstructure | Prevents formation of dense clumps | Creates high-porosity layers for mass transport |

Elevate Your Electrode Performance with KINTEK Precision

Uniform dispersion is the foundation of high-performance electrochemistry. At KINTEK, we understand the critical role of preparation in catalyst development. Backed by expert R&D and world-class manufacturing, we provide high-performance ultrasonic cleaners and lab high-temp furnaces—including Muffle, Tube, Rotary, Vacuum, and CVD systems—all customizable to your unique research needs.

Ready to optimize your mass transport and achieve superior coating consistency? Contact KINTEK today to discover how our advanced laboratory solutions can refine your material synthesis and electrode fabrication process.

Visual Guide

References

- Sun Seo Jeon, Hyunjoo Lee. Degradation of NiMo Catalyst Under Intermittent Operation of Anion Exchange Membrane Water Electrolyzer and its Mitigation by Carbon Encapsulation. DOI: 10.1002/aenm.202501800

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What are the alternative names for a Laboratory Furnace? Find the Right High-Temperature Tool for Your Lab

- What are the requirements for an alumina boat for Mn2AlB2 sintering? Ensure High-Purity Material Processing

- What is the specific function of the water circulation cooler in zirconium sponge processing? Key for Purity & Safety

- How does a nitrogen nozzle system influence the quality of components? Optimize Cooling for Structural Integrity

- What are the main composition percentages of alumina tubes? Optimize Performance for High-Temperature Applications

- What are the primary functions of a Quartz Flow Reactor? Enhance Precision in Oxidation Research

- What is the critical physical function of a laboratory electric blast drying oven in phosphor gel treatment?

- What key functions do graphite molds serve during the hot press sintering? Enhance Ti/Al2O3 Composite Quality