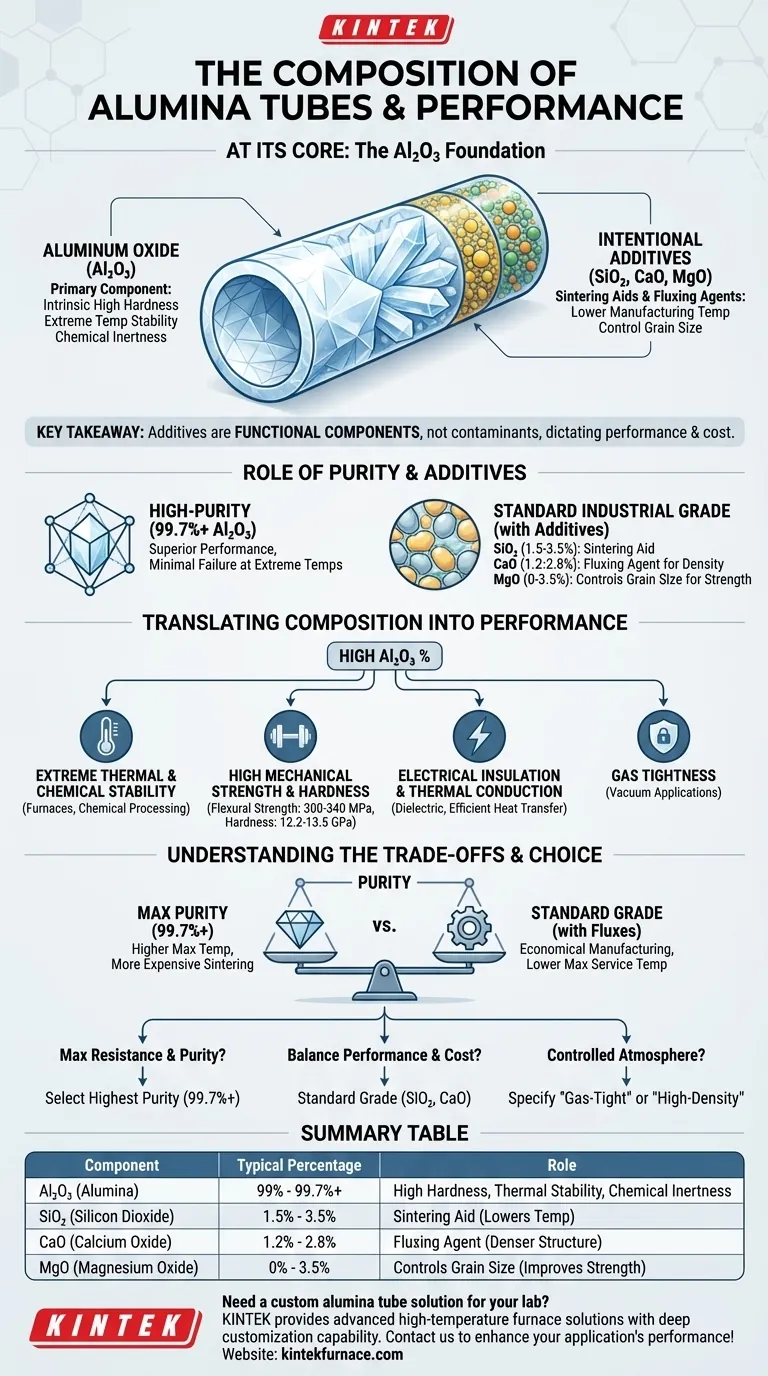

At its core, the composition of an alumina tube is overwhelmingly aluminum oxide (Al₂O₃), but the exact percentage varies by grade. High-purity tubes can be over 99.7% Al₂O₃, while standard industrial grades intentionally include small percentages of other oxides like Silicon Dioxide (SiO₂), Calcium Oxide (CaO), and Magnesium Oxide (MgO) to aid in manufacturing and refine specific properties.

The key takeaway is that the small amounts of non-alumina materials are not contaminants, but deliberate additives. The percentage of pure Al₂O₃ versus these additives directly dictates the tube's performance, cost, and suitability for a specific high-temperature or high-stress application.

The Role of Alumina (Al₂O₃) Purity

The fundamental properties of any alumina ceramic are derived from its primary component, aluminum oxide. The purity level of this base material is the single most important factor determining its ultimate performance capabilities.

The Foundation: 99%+ Al₂O₃

Pure Al₂O₃ is responsible for the material's most sought-after characteristics. Its stable, crystalline structure provides intrinsic high hardness, exceptional temperature stability, and broad chemical inertness.

A tube with 99.7% or higher purity is considered a premium product, valued for its superior performance in the most demanding environments. This high purity minimizes potential points of failure or reaction at extreme temperatures.

Why Additives Are Intentionally Included

While maximum purity seems ideal, standard-grade alumina tubes contain specific additives for practical reasons. These are not impurities but functional components that modify the material's behavior during manufacturing.

The Function of SiO₂, CaO, and MgO

The most common additives—Silicon Dioxide (SiO₂: 1.5-3.5%), Calcium Oxide (CaO: 1.2-2.8%), and Magnesium Oxide (MgO: 0-3.5%)—act as sintering aids or fluxing agents.

During production, these oxides melt at a lower temperature than pure alumina. This process helps bond the Al₂O₃ grains together into a dense, non-porous solid at a lower manufacturing temperature, reducing energy consumption and cost.

These additives also help control the final grain size of the ceramic, which has a direct impact on its mechanical strength and fracture resistance.

Translating Composition into Performance

The final chemical makeup and physical structure determine the tube's real-world capabilities. Understanding this link is key to selecting the right material for your application.

Extreme Thermal and Chemical Stability

The high percentage of Al₂O₃ is what allows these tubes to operate in extreme temperatures and corrosive environments. This makes them ideal for furnace components, chemical processing, and metallurgical applications where other materials would quickly degrade.

High Mechanical Strength and Hardness

The dense, sintered structure gives alumina tubes a high flexural strength (300-340 MPa) and hardness (12.2-13.5 GPa). This allows them to resist physical stress, wear, and abrasion, even at elevated temperatures.

Electrical Insulation and Thermal Conduction

Alumina is an excellent electrical insulator (dielectric), making it perfect for protecting heating elements or electrical lead-outs. At the same time, it possesses relatively good thermal conductivity for a ceramic, allowing it to efficiently and uniformly transfer heat, a vital property for furnace tubes.

Gas Tightness for Vacuum Applications

The dense, vitrified structure created during sintering makes the tube walls gas-tight. This is critical for applications in vacuum furnaces or where a controlled atmosphere must be maintained without leakage.

Understanding the Trade-offs

Choosing the right alumina grade involves balancing performance requirements against practical and economic constraints.

Purity vs. Cost and Manufacturability

The primary trade-off is between purity and cost. Sintering very high-purity alumina requires extremely high temperatures, making it a more expensive process.

The addition of fluxes like SiO₂ and CaO lowers the required sintering temperature, making manufacturing more cost-effective for a wide range of general-purpose applications.

Impact on Maximum Service Temperature

While additives make manufacturing easier, they can slightly compromise the material's ultimate performance. The glassy phase formed by these additives at the grain boundaries can soften at a lower temperature than the alumina grains themselves.

Therefore, a 99.7% pure alumina tube will typically have a higher maximum service temperature than a standard grade containing more fluxing agents.

Making the Right Choice for Your Goal

Your application dictates the optimal composition. Use the following guidelines to make an informed decision.

- If your primary focus is maximum temperature resistance and chemical purity: Select the highest purity alumina available (99.7% or greater) to minimize reactivity and ensure performance in the most extreme conditions.

- If your primary focus is a balance of high-temperature performance and cost: A standard grade containing SiO₂ and CaO is a robust, reliable, and economical choice for most furnace and industrial applications.

- If your primary focus is creating a controlled vacuum or gas environment: Ensure the tube is specified as "gas-tight" or "high-density," as this property is a result of the manufacturing process more than just the raw composition.

Ultimately, understanding that composition is a tool to achieve specific properties empowers you to select the precise material for your technical needs.

Summary Table:

| Component | Typical Percentage | Role |

|---|---|---|

| Al₂O₃ (Alumina) | 99% - 99.7%+ | Provides high hardness, thermal stability, and chemical inertness |

| SiO₂ (Silicon Dioxide) | 1.5% - 3.5% | Acts as a sintering aid to lower manufacturing temperature |

| CaO (Calcium Oxide) | 1.2% - 2.8% | Functions as a fluxing agent for denser structure |

| MgO (Magnesium Oxide) | 0% - 3.5% | Controls grain size to improve mechanical strength |

Need a custom alumina tube solution for your lab? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to enhance your application's performance and efficiency!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

People Also Ask

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What core process conditions does a tube furnace provide? Mastering Catalyst Precursor Treatment

- How does a tube heating furnace facilitate the carbon coating process? Boost Layered Oxide Conductivity

- How does a vertical tube furnace facilitate the simulation of the industrial sintering process for iron ores?

- What function does a tube furnace serve in the PVT growth of J-aggregate molecular crystals? Mastery of Thermal Control