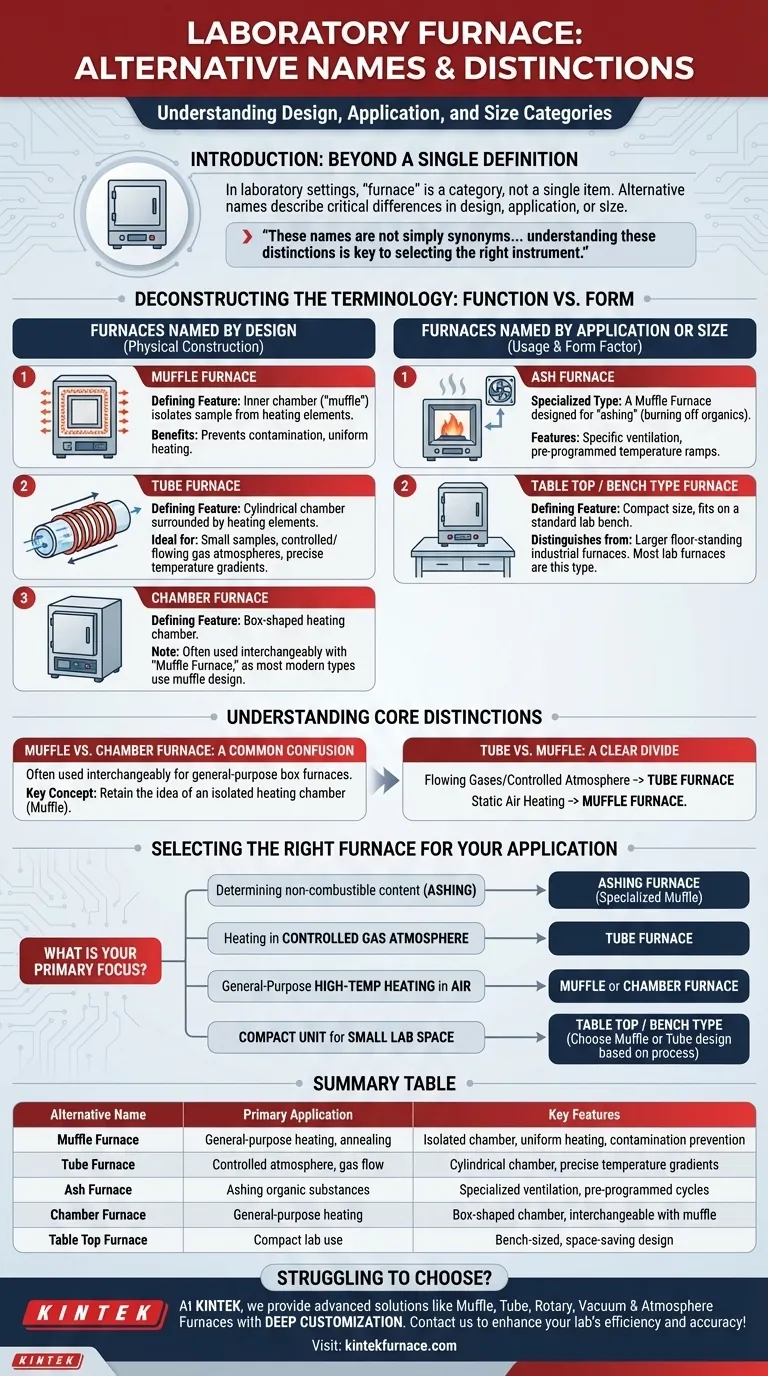

In laboratory settings, the term "furnace" is not a single definition but a category of high-temperature heating equipment. A general-purpose laboratory furnace is often also known as a Muffle Furnace, Chamber Furnace, or Table Top (Bench Type) Furnace, with more specialized versions called an Ash Furnace or Tube Furnace.

The various names for a laboratory furnace are not simply synonyms. They describe critical differences in the furnace's design, primary application, or physical size, and understanding these distinctions is key to selecting the right instrument.

Deconstructing the Terminology: Function vs. Form

The alternative names for a laboratory furnace can be understood by categorizing them based on either their core design and construction or their intended scientific application.

Furnaces Named by Design

These names describe the physical construction of the heating chamber.

Muffle Furnace

A Muffle Furnace is arguably the most common type. Its defining feature is an inner chamber (the "muffle") that isolates the sample from direct contact with the heating elements.

This design prevents contamination from combustion byproducts of the heating elements and ensures more uniform temperature distribution.

Tube Furnace

A Tube Furnace features a cylindrical chamber, typically made of ceramic or metal alloy, that the heating elements surround.

Their shape is ideal for heating small samples, processing materials in a controlled or flowing gas atmosphere, or for experiments that require a precise temperature gradient along the length of the tube.

Chamber Furnace

The term Chamber Furnace is a more general descriptor for any furnace with a box-shaped heating chamber.

It is often used interchangeably with "Muffle Furnace," as most modern chamber furnaces are, by design, muffle furnaces.

Furnaces Named by Application or Size

These names describe what the furnace is used for or how large it is.

Ash Furnace

An Ash Furnace (or ashing furnace) is a specialized type of muffle furnace designed for "ashing"—the process of burning off organic substances to determine the non-combustible ash content.

These often feature specific ventilation to handle the fumes produced during combustion and programming designed for the precise temperature ramps required for ashing protocols.

Table Top / Bench Type Furnace

This name simply refers to the furnace's size and form factor. A Table Top or Bench Type furnace is compact enough to be placed on a standard laboratory workbench.

This distinguishes it from larger, floor-standing industrial or production furnaces. Most laboratory furnaces fall into this category.

Understanding the Core Distinctions

While the underlying technology of a temperature controller, heating elements, and an insulated chamber is the same, the configuration dictates its proper use. Misunderstanding the terminology can lead to selecting the wrong tool for a critical process.

Muffle vs. Chamber Furnace: A Common Confusion

While technically distinct, in practice, most manufacturers use Chamber Furnace and Muffle Furnace interchangeably to describe a general-purpose, front-loading box furnace. The key concept to retain is the isolated heating chamber.

Application-Specific vs. General-Purpose

An Ash Furnace is a purpose-built muffle furnace. While you can perform ashing in a general-purpose muffle furnace, a dedicated Ash Furnace is optimized for the task with better ventilation and pre-programmed cycles.

Tube vs. Muffle: A Clear Divide

The choice between a tube and muffle furnace is fundamental. If your process involves flowing gases or a controlled atmosphere, a Tube Furnace is almost always the correct choice. For heating samples in static air, a Muffle Furnace is the standard.

Selecting the Right Furnace for Your Application

Choosing the correct furnace begins with identifying your primary experimental need.

- If your primary focus is determining the non-combustible content of a sample: You are looking for an Ashing Furnace, which is a specialized type of Muffle Furnace.

- If your primary focus is heating samples within a controlled gas atmosphere: A Tube Furnace is the correct instrument for your needs.

- If your primary focus is general-purpose high-temperature heating, annealing, or heat-treating in air: A general Muffle Furnace or Chamber Furnace will provide the necessary capabilities.

- If your primary focus is finding a compact unit for a small lab space: Specify a Table Top or Bench Type furnace, then determine whether you need a muffle or tube design based on your process.

Understanding these distinctions ensures you select the precise tool required for accurate and repeatable results.

Summary Table:

| Alternative Name | Primary Application | Key Features |

|---|---|---|

| Muffle Furnace | General-purpose heating, annealing | Isolated chamber, uniform heating, contamination prevention |

| Tube Furnace | Controlled atmosphere, gas flow | Cylindrical chamber, precise temperature gradients |

| Ash Furnace | Ashing organic substances | Specialized ventilation, pre-programmed cycles |

| Chamber Furnace | General-purpose heating | Box-shaped chamber, interchangeable with muffle |

| Table Top Furnace | Compact lab use | Bench-sized, space-saving design |

Struggling to choose the right laboratory furnace for your unique needs? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions. Our product line includes Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your experimental requirements. Contact us today to discuss how we can enhance your lab's efficiency and accuracy with a tailored furnace solution!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How do you prevent maintenance on a muffle furnace? Extend Lifespan with Proactive Care

- How do you clean a muffle furnace? Ensure Peak Performance and Longevity

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- How does a laboratory muffle furnace facilitate the biomass carbonization process? Achieve Precise Biochar Production

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals