A nitrogen nozzle system dictates component quality by controlling the rate and uniformity of thermal energy removal through forced convection. By injecting high-pressure nitrogen directly into the furnace, the system manages the cooling velocity across varying geometries, which is the primary factor in preventing physical deformation and internal structural imbalances.

The core function of a nitrogen nozzle system is to provide a controlled environment for rapid cooling via convective heat exchange. Its success depends on balancing cooling speeds across different wall thicknesses to prevent buckling and the detrimental redistribution of residual stresses.

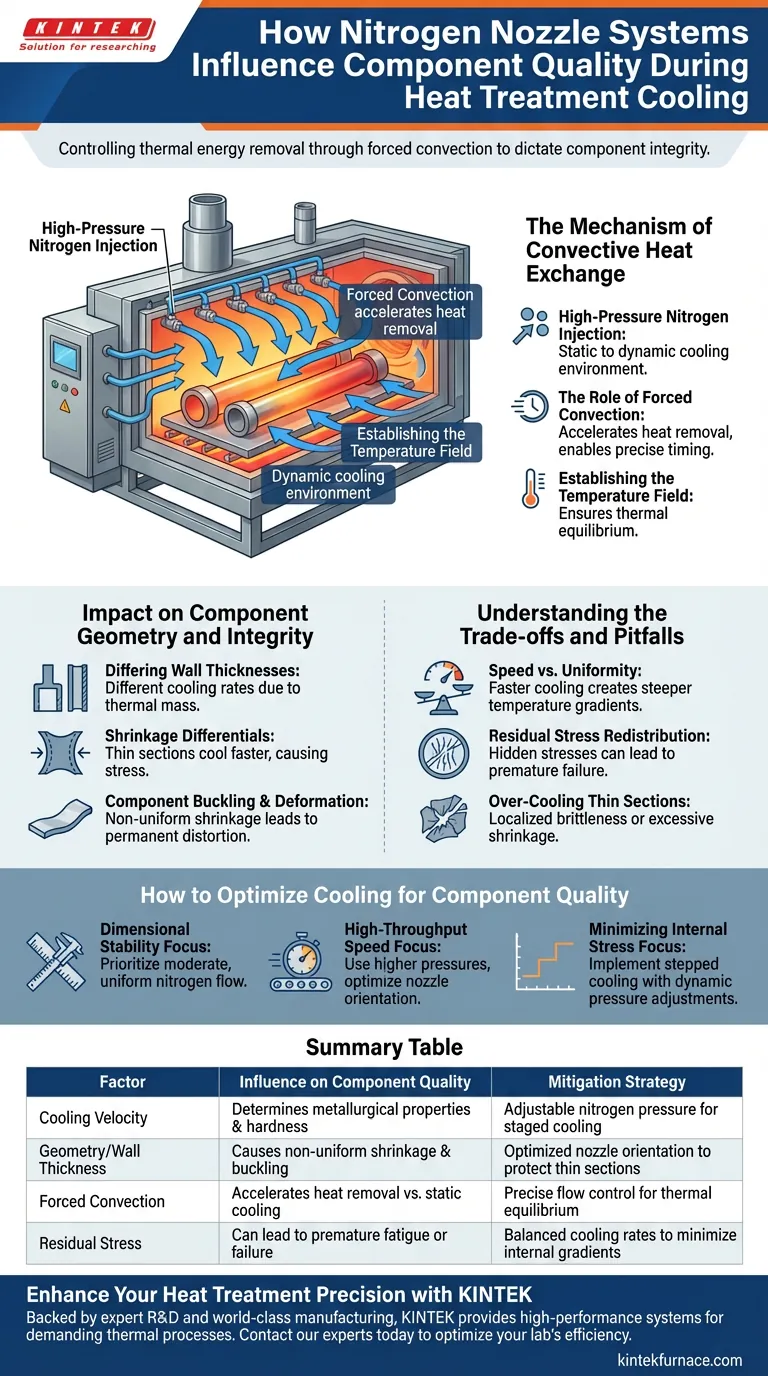

The Mechanism of Convective Heat Exchange

High-Pressure Nitrogen Injection

The system operates by introducing high-pressure nitrogen gas into the heated furnace environment. This process transforms a static cooling environment into a dynamic one, where the gas acts as a medium for rapid energy transfer.

The Role of Forced Convection

Forced convection occurs as the nitrogen flows over the surfaces of the hot components. This movement significantly accelerates the removal of heat compared to natural radiation or static cooling, allowing for the precise timing required in specific heat treatment cycles.

Establishing the Temperature Field

The arrangement and pressure of the nozzles create a specific temperature field within the furnace. A well-designed system ensures that the nitrogen reaches all surfaces of the component, attempting to maintain as much thermal equilibrium as possible during the rapid temperature drop.

Impact on Component Geometry and Integrity

The Challenge of Differing Wall Thicknesses

Large components often feature complex geometries with both thin-walled sections and thick, dense cores. Nitrogen nozzles must be managed carefully because these different regions naturally lose heat at different rates due to their thermal mass.

Shrinkage Differentials

If the nitrogen flow is too aggressive or poorly directed, thin sections will cool and shrink much faster than the thick core. This differential in shrinkage rates is the primary driver of physical defects during the cooling phase.

Component Buckling and Deformation

When shrinkage is non-uniform, the resulting mechanical tension can cause the component to buckle or warp. This permanent deformation often renders high-precision components useless, as they no longer meet dimensional tolerances.

Understanding the Trade-offs and Pitfalls

Speed vs. Uniformity

The primary trade-off in nitrogen cooling is the balance between cooling speed and thermal uniformity. While faster cooling can achieve desired metallurgical properties, it increases the risk of creating a steep temperature gradient that leads to cracking or warping.

Residual Stress Redistribution

Even if a component does not visibly buckle, improper cooling can lead to the redistribution of residual stresses. These internal stresses may remain hidden until the component is in service, potentially leading to premature fatigue or unexpected failure.

Over-Cooling Thin Sections

A common pitfall is focusing solely on the cooling requirements of the thickest part of the component. This often results in the over-cooling of thinner sections, which can lead to localized brittleness or excessive shrinkage.

How to Optimize Cooling for Component Quality

Applying Systems to Your Project

To ensure the highest component quality, the nitrogen nozzle system must be tuned to the specific geometry of the parts being treated.

- If your primary focus is dimensional stability: Prioritize a more moderate, uniform nitrogen flow that minimizes the temperature delta between thin and thick sections.

- If your primary focus is high-throughput speed: Utilize higher pressures but ensure the nozzle orientation is optimized to prevent direct impingement on thin-walled areas.

- If your primary focus is minimizing internal stress: Implement a stepped cooling approach where nitrogen pressure is adjusted dynamically to allow the core temperature to "catch up" with the surface.

The precision of a nitrogen nozzle system is the ultimate safeguard against the thermal imbalances that compromise the structural integrity of heat-treated components.

Summary Table:

| Factor | Influence on Component Quality | Mitigation Strategy |

|---|---|---|

| Cooling Velocity | Determines metallurgical properties and hardness. | Adjustable nitrogen pressure for staged cooling. |

| Geometry/Wall Thickness | Causes non-uniform shrinkage and buckling. | Optimized nozzle orientation to protect thin-walled areas. |

| Forced Convection | Accelerates heat removal compared to static cooling. | Precise flow control to maintain thermal equilibrium. |

| Residual Stress | Can lead to premature fatigue or failure. | Balanced cooling rates to minimize internal gradients. |

Enhance Your Heat Treatment Precision with KINTEK

Don't let thermal imbalances compromise your component integrity. Backed by expert R&D and world-class manufacturing, KINTEK provides high-performance Muffle, Tube, Vacuum, and CVD systems designed for the most demanding thermal processes. Our customizable high-temperature lab furnaces ensure your specific cooling and heating requirements are met with unparalleled accuracy.

Ready to optimize your lab's efficiency? Contact our experts today to discover how our tailored solutions can improve your material outcomes.

Visual Guide

References

- Indira Dey, Konrad Wegener. Comprehensive Distortion Analysis of a Laser Direct Metal Deposition (DMD)-Manufactured Large Prototype Made of Soft Martensitic Steel 1.4313. DOI: 10.3390/jmmp8020078

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What role do vacuum-sealed high-purity silica ampoules play in phase equilibrium experiments? Enhance Sample Integrity

- What role does a graphite crucible play during alloy and ceramic shell interaction experiments? Optimize Your Lab Results

- What functions does a high-density graphite crucible perform? More Than a Container for Copper Refining

- What materials are commonly used for furnace tubes to withstand high heat? Choose the Best for Your Lab

- How are constant temperature water baths and drying ovens utilized to verify bonding quality? Master EN 314-1 Testing

- How does the circulating water vacuum pump work? Uncover the Liquid Piston Mechanism

- How does the hardness of alumina ceramics compare to other materials? Discover Its Superior Wear Resistance

- What are the alternative names for a Laboratory Furnace? Find the Right High-Temperature Tool for Your Lab