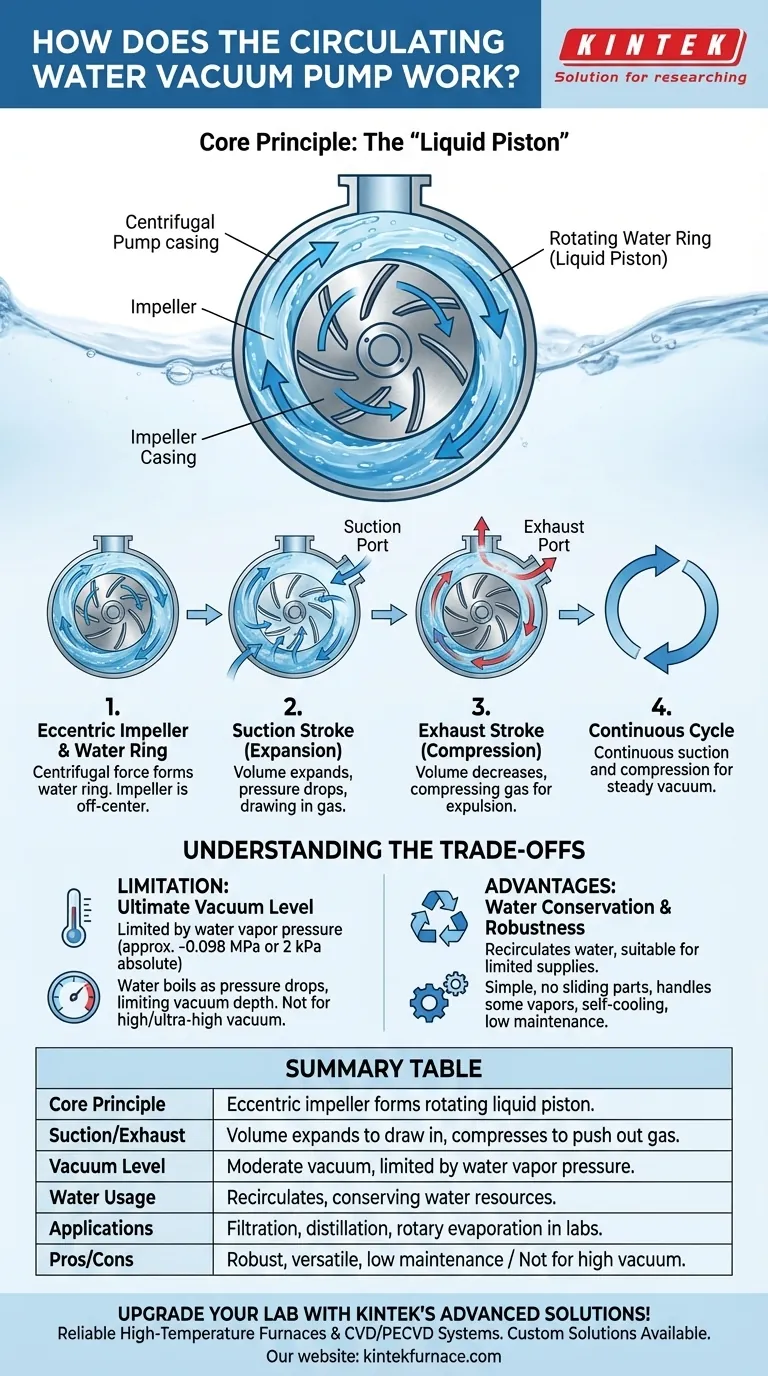

At its core, a circulating water vacuum pump works by using a rapidly spinning, off-center impeller to create a ring of water. This rotating water ring acts like a series of liquid pistons. The space between the impeller blades and the water ring first expands to suck in gas, then compresses to push that gas out, generating a continuous vacuum.

The key insight is that the pump doesn't use the water's flow to "siphon" air out. Instead, it uses the physical mass of a rotating water ring as a dynamic seal and piston, creating vacuum through a repeating cycle of volume expansion and compression.

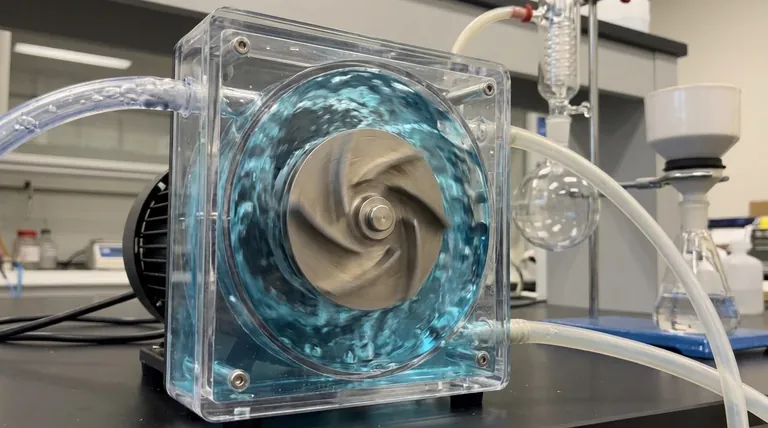

The Core Principle: The "Liquid Piston"

To understand how this pump works, you must visualize the relationship between the impeller and the water inside the pump casing. The entire process is a clever mechanical action.

The Eccentric Impeller

The foundation of the pump's operation is its eccentrically mounted impeller. This means the rotor with its blades is deliberately placed off-center within the cylindrical pump housing. This offset is critical.

Forming the Water Ring

When the pump is turned on, the impeller spins at high speed. It picks up the water from the reservoir and, due to centrifugal force, throws it against the outer wall of the pump casing. This forms a stable, uniform ring of water that co-rotates with the impeller.

The Suction Stroke (Expansion)

Because the impeller is off-center, as its blades rotate, the space between the hub of the impeller and the inner surface of the water ring constantly changes. On one side of the rotation, the blades are moving away from the water ring, causing the volume of this space to increase. This expansion creates a drop in pressure, drawing gas in from the system through the suction port.

The Exhaust Stroke (Compression)

As the same blades continue to rotate to the other side, the off-center design forces them to move closer to the water ring. This decreases the volume of the space, compressing the gas that was just drawn in. This compressed gas is then forced out through the exhaust port.

Continuous, Cyclical Action

This process of suction and compression happens continuously with every blade for every rotation of the impeller. This ongoing cycle creates a steady, reliable vacuum.

Understanding the Trade-offs

While effective, this pump design has specific advantages and limitations you must consider. It is a workhorse for certain tasks but unsuitable for others.

Limitation: Ultimate Vacuum Level

The deepest vacuum a water circulating pump can achieve is limited by the vapor pressure of the water itself. As pressure drops, the water will begin to boil (even at room temperature), and the pump will just be pumping water vapor. This typically limits its ultimate vacuum to around -0.098 MPa (or 2 kPa absolute pressure), which is considered a moderate or rough vacuum.

Advantage: Water Conservation

The system uses a fixed amount of water in a reservoir that is constantly recirculated. This is a major advantage for laboratories that have limited water supplies or low water pressure, as it does not rely on a constant tap water connection.

Advantage: Robustness and Versatility

The design has no sliding metal parts with tight tolerances, making it mechanically simple and highly robust. It can handle some chemical vapors that might damage more sensitive, oil-based pumps. The circulating water also serves to cool the pump and any attached reaction devices.

Making the Right Choice for Your Application

Use these points to determine if a circulating water vacuum pump meets the needs of your project.

- If your primary focus is general lab vacuum for tasks like filtration, distillation, or rotary evaporation: This pump is an excellent, cost-effective, and reliable choice.

- If your primary focus is achieving high or ultra-high vacuum for sensitive surface science or mass spectrometry: This pump is not suitable; its vacuum is physically limited by the water's properties.

- If your primary focus is water conservation and operational simplicity: The self-contained, recirculating design makes it an ideal and low-maintenance tool.

Understanding this pump's "liquid piston" principle allows you to select and use it effectively for the right applications.

Summary Table:

| Feature | Description |

|---|---|

| Core Principle | Uses an eccentric impeller to form a rotating water ring that acts as a liquid piston |

| Suction Stroke | Volume expands to draw in gas, creating vacuum |

| Exhaust Stroke | Volume compresses to push out gas |

| Vacuum Level | Moderate vacuum, limited by water vapor pressure (around -0.098 MPa) |

| Water Usage | Recirculates water, conserving resources |

| Applications | Filtration, distillation, rotary evaporation in labs |

| Advantages | Robust, handles chemical vapors, self-cooling, low maintenance |

| Limitations | Not for high or ultra-high vacuum applications |

Upgrade your lab's vacuum capabilities with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs. Contact us today to discuss how our products can enhance your efficiency and performance!

Visual Guide

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- CF KF Flange Vacuum Electrode Feedthrough Lead Sealing Assembly for Vacuum Systems

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What role does a high-alumina ceramic boat play during Ni-Co doped carbon nanotube growth? Key CVD Synthesis Insights

- What is the necessity of an observation window in a magnesium combustion chamber? Elevate Your Visual Data Analysis

- Why is a covered aluminum crucible necessary for g-C3N5 thermal polycondensation? Optimize Your Synthesis Atmosphere

- What is the role of a vacuum pass-box and a high-capacity vacuum pump? Ensuring Safety in Battery Recycling

- What role does a high-purity graphite mold play during the SPS sintering process of Al2O3-TiC? Unlock Process Efficiency

- What are the key characteristics of the circulating water multifunctional vacuum pump? Discover Clean, Oil-Free Lab Solutions

- What is the function of a forced air drying oven in zeolite preparation? Protect Pore Integrity and Ensure Uniformity

- What is the function of a laboratory hydraulic press in LLZO green body prep? Ensure High Density and Ionic Conductivity