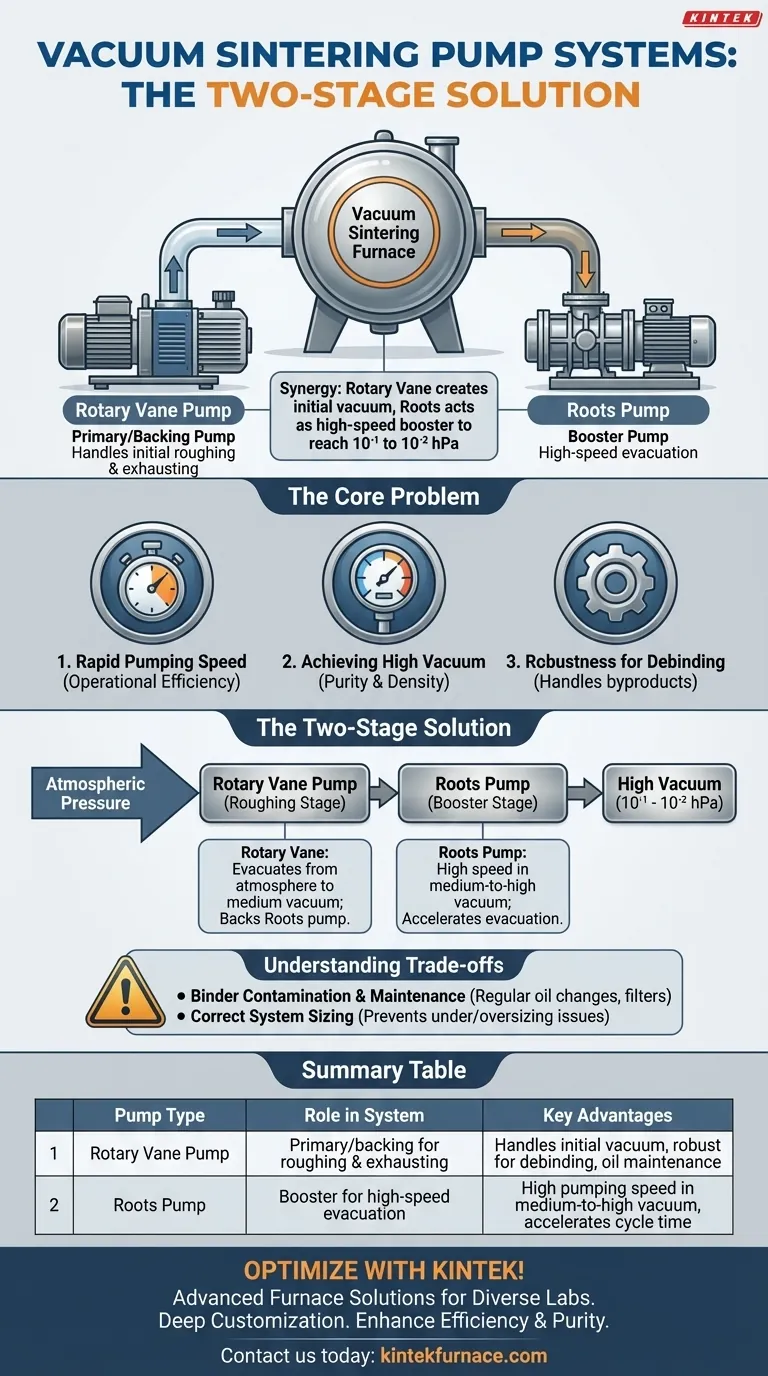

For vacuum sintering furnaces, the industry-standard configuration is a two-stage pumping system combining a rotary vane pump with a Roots pump. This combination is engineered to rapidly and reliably achieve the final high-vacuum pressures required for producing high-quality sintered parts, typically in the range of 10⁻¹ to 10⁻² hPa.

The core principle is a division of labor: the rotary vane pump creates the initial vacuum, and the Roots pump acts as a high-speed booster. This partnership is not just about reaching a deep vacuum; it's about getting there quickly and handling the harsh byproducts of the sintering process.

The Core Problem: More Than Just Emptying a Chamber

Achieving the right vacuum in a sintering furnace is a multi-faceted engineering challenge. The pump system must satisfy three critical requirements simultaneously to ensure process integrity and product quality.

Requirement 1: Rapid Pumping Speed

The speed at which the furnace is evacuated directly impacts cycle time and operational efficiency. A faster pump-down means higher throughput, which is a key economic driver in industrial applications from aerospace to medical device manufacturing.

Requirement 2: Achieving High Vacuum

Sintering under a high vacuum (10⁻¹ to 10⁻² hPa) is essential for preventing oxidation and removing trapped gases from the material. This ensures the final product has superior density, strength, and purity.

Requirement 3: Robustness for Debinding

The debinding phase is often the most demanding part of the process for the vacuum system. Pumps must be robust enough to handle and extract large volumes of evaporated binder substances without performance degradation or failure.

The Two-Stage Solution: How the Pumps Work Together

The rotary vane and Roots pump combination is favored because each pump excels at a different stage of the evacuation process. They work in series to create a system that is far more effective than either pump would be alone.

The Primary Pump: The Rotary Vane Pump

The rotary vane pump is the workhorse of the system. It is a "wet" or oil-sealed positive displacement pump that performs two crucial functions.

First, it does the initial "roughing," evacuating the furnace from atmospheric pressure down to the medium vacuum range. Second, it serves as the backing pump for the Roots pump, continuously exhausting the gas that the Roots pump moves.

The Booster: The Roots Pump

The Roots pump is a "dry" positive displacement pump that acts as a vacuum booster. It cannot exhaust directly to atmosphere and requires the backing of the rotary vane pump to function.

Its primary advantage is its extremely high pumping speed in the medium-to-high vacuum range. Once the rotary vane pump has roughed down the chamber, the Roots pump kicks in, dramatically accelerating the evacuation rate and enabling the system to reach the target final pressure much more quickly.

Understanding the Trade-offs

While this combination is the standard, it is not without its operational considerations. Understanding its limitations is key to successful implementation and maintenance.

Binder Contamination and Maintenance

Binder vapors extracted during debinding can contaminate the oil in the rotary vane pump. This can degrade pump performance and lead to premature failure if not managed.

This requires a rigorous maintenance schedule, including regular oil changes and the potential use of inlet traps or filters to capture binder contaminants before they reach the pump.

Correct System Sizing

The efficiency of the entire system depends on correctly sizing the pumps relative to each other and to the furnace volume.

An undersized system will fail to meet cycle time or final pressure requirements. An oversized system increases initial capital cost and energy consumption without providing a proportional benefit. Proper engineering calculations are critical.

Making the Right Choice for Your Application

Selecting the ideal pump configuration requires balancing performance goals with the specific demands of your materials and processes.

- If your primary focus is process efficiency and cycle time: Invest in a properly sized Roots booster, as this will have the greatest impact on reducing pump-down time.

- If your primary focus is ultimate material purity: Ensure the rotary vane pump is a high-quality, low-backstreaming model and that the entire system is designed to prevent contamination.

- If your primary focus is handling high binder content: Select robust pumps designed for harsh duty and implement a strict, preventative maintenance plan for oil and filters.

Ultimately, the synergy between the rotary vane pump and the Roots booster provides the most effective and economical solution for the demands of modern vacuum sintering.

Summary Table:

| Pump Type | Role in System | Key Advantages |

|---|---|---|

| Rotary Vane Pump | Primary/backing pump for roughing and exhausting | Handles initial vacuum, robust for debinding, requires oil maintenance |

| Roots Pump | Booster pump for high-speed evacuation | High pumping speed in medium-to-high vacuum, accelerates cycle time |

Optimize your vacuum sintering process with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature furnace systems, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing efficiency and material purity. Contact us today to discuss how we can support your specific requirements and drive your success!

Visual Guide

Related Products

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the common applications of a rotary tube furnace? Achieve Uniform Heating for Powders and Granules

- What are the main advantages of rotary tube furnaces? Achieve Superior Uniformity and Efficiency in Thermal Processing

- What are the key features of a rotary furnace? Achieve Superior Uniformity and Control

- What other fields utilize rotary tube furnaces? Discover Versatile Heating Solutions for Multiple Industries

- What are the benefits of continuous sample movement in rotary tube furnaces? Boost Uniformity and Efficiency