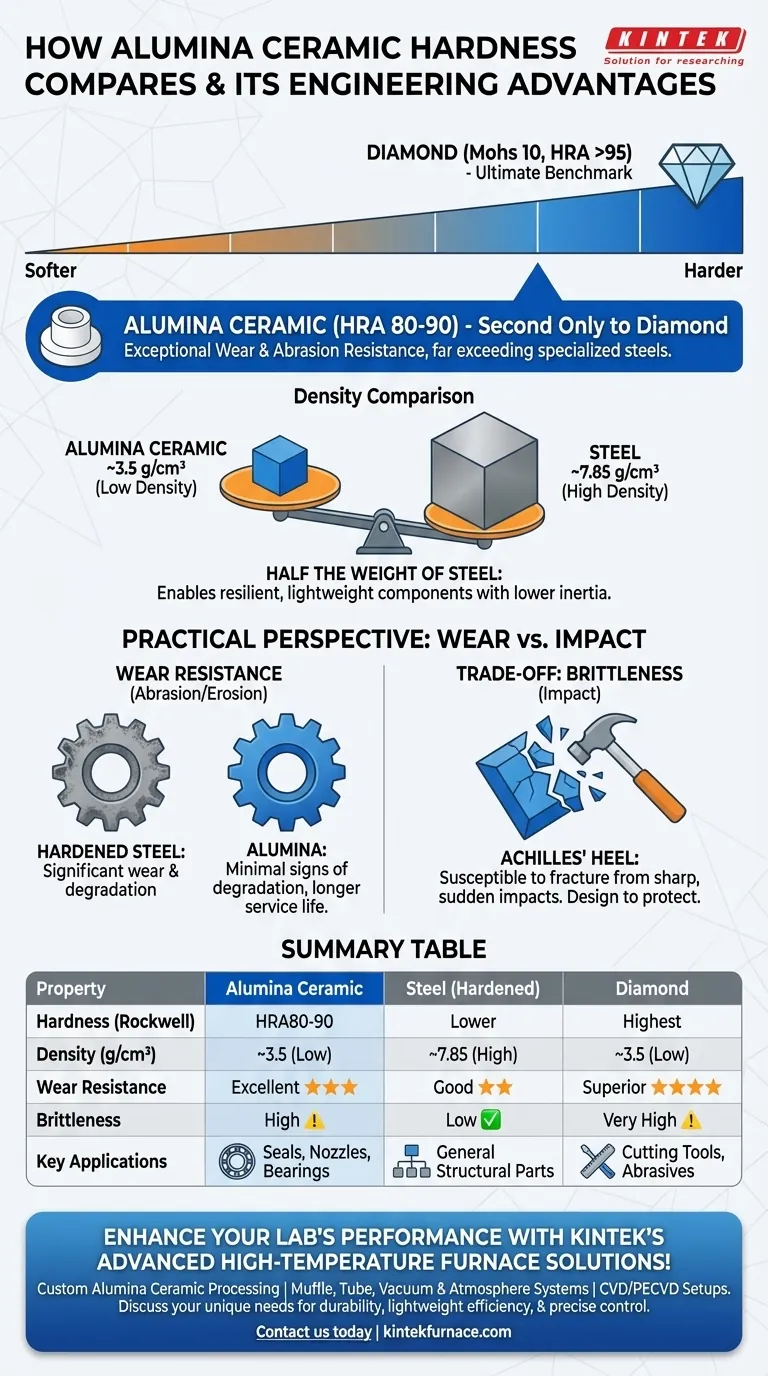

In terms of absolute hardness, alumina ceramic is one of the most formidable materials used in modern engineering, surpassed only by diamond. With a Rockwell hardness rating of HRA80-90, its ability to resist surface wear and abrasion far exceeds that of even specialized wear-resistant steel and stainless steel.

While alumina's extreme hardness provides exceptional wear resistance, its true engineering advantage is the combination of this durability with a density half that of steel. This pairing enables the creation of highly resilient components without the weight penalty of traditional metals.

A Practical Perspective on Hardness

Understanding a material's hardness rating is less about the number itself and more about what it means for performance and longevity in a real-world application. Hardness is a direct indicator of wear resistance.

The Comparison to Metals

The most common point of comparison is steel. Alumina's hardness, which translates into superior wear resistance, means it will last significantly longer in applications involving abrasion, erosion, or sliding contact.

Where a hardened steel component might wear down and require replacement, an alumina ceramic equivalent often shows minimal signs of degradation, extending service life and reducing maintenance downtime.

The Diamond Benchmark

Stating that alumina is "second only to diamond" places it in the highest tier of material hardness. Diamond sits at the top of the Mohs scale (10) and is the hardest known natural material.

While alumina is not as hard as diamond, it is vastly harder than most other materials and offers a much more cost-effective solution for industrial applications where extreme wear resistance is the primary requirement.

Understanding the Trade-offs and Properties

No material choice is made in a vacuum. While alumina's hardness is its defining feature, other properties are critical to consider for a successful application.

Key Advantage: Low Density

The density of alumina ceramics is approximately 3.5 g/cm³, which is roughly half that of steel (which is ~7.85 g/cm³).

This is a significant advantage. Using alumina can drastically reduce the weight of components, which in turn reduces the overall load on equipment. For moving parts, this means lower inertia, allowing for higher speeds and reduced energy consumption.

The Ceramic's Achilles' Heel: Brittleness

As a rule, extremely hard materials tend to be brittle. Alumina is no exception. While it excels at resisting surface scratches and gradual wear, it can be susceptible to fracture from sudden, sharp impacts.

This trade-off between hardness and toughness is a fundamental consideration. The design must protect the ceramic component from direct, high-energy impacts to leverage its superior wear resistance.

Other Defining Characteristics

Beyond hardness, alumina also offers high thermal stability and excellent electrical insulation properties. This makes it a multifunctional material suitable for environments where high temperatures or electrical currents are a concern.

How to Apply This to Your Project

Your choice of material should be driven by the primary challenge you are trying to solve.

- If your primary focus is maximizing wear resistance: Alumina is a premier choice for components like seals, nozzles, bearings, and liners where abrasion is the main cause of failure.

- If your primary focus is high performance with low weight: Alumina's combination of hardness and low density is ideal for moving parts in precision machinery that require both durability and low inertia.

- If your primary focus is resisting high-impact forces: You must carefully evaluate alumina's brittleness and either design the system to mitigate shock or consider a tougher, albeit less hard, material.

By balancing its world-class hardness against its inherent brittleness, you can effectively use alumina ceramic to solve your most demanding wear-related engineering challenges.

Summary Table:

| Property | Alumina Ceramic | Steel (Hardened) | Diamond |

|---|---|---|---|

| Hardness (Rockwell) | HRA80-90 | Lower than alumina | Highest |

| Density (g/cm³) | ~3.5 | ~7.85 | ~3.5 |

| Wear Resistance | Excellent | Good | Superior |

| Brittleness | High | Low | Very High |

| Key Applications | Seals, nozzles, bearings | General structural parts | Cutting tools, abrasives |

Enhance your lab's performance with KINTEK's advanced high-temperature furnace solutions! Our expertise in R&D and in-house manufacturing allows us to provide tailored alumina ceramic processing for diverse laboratories. From Muffle and Tube Furnaces to Vacuum & Atmosphere Systems and CVD/PECVD setups, we offer deep customization to meet your unique experimental needs. Contact us today to discuss how our solutions can bring superior durability, lightweight efficiency, and precise thermal control to your projects!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

People Also Ask

- In which industries is the tube furnace commonly used? Essential for Materials Science, Energy, and More

- What is flash vacuum pyrolysis and how is a tube furnace utilized in this process? Unlock High-Temp Chemical Reactions

- What other types of reactions can tube furnaces be used for? Explore Versatile Thermal Processes for Your Lab

- How do roller kilns and tube furnaces differ in their use of Alumina ceramic tubes? Compare Transport vs. Containment

- What types of production processes benefit from the thermal uniformity of tube furnaces? Enhance Precision in Material Processing