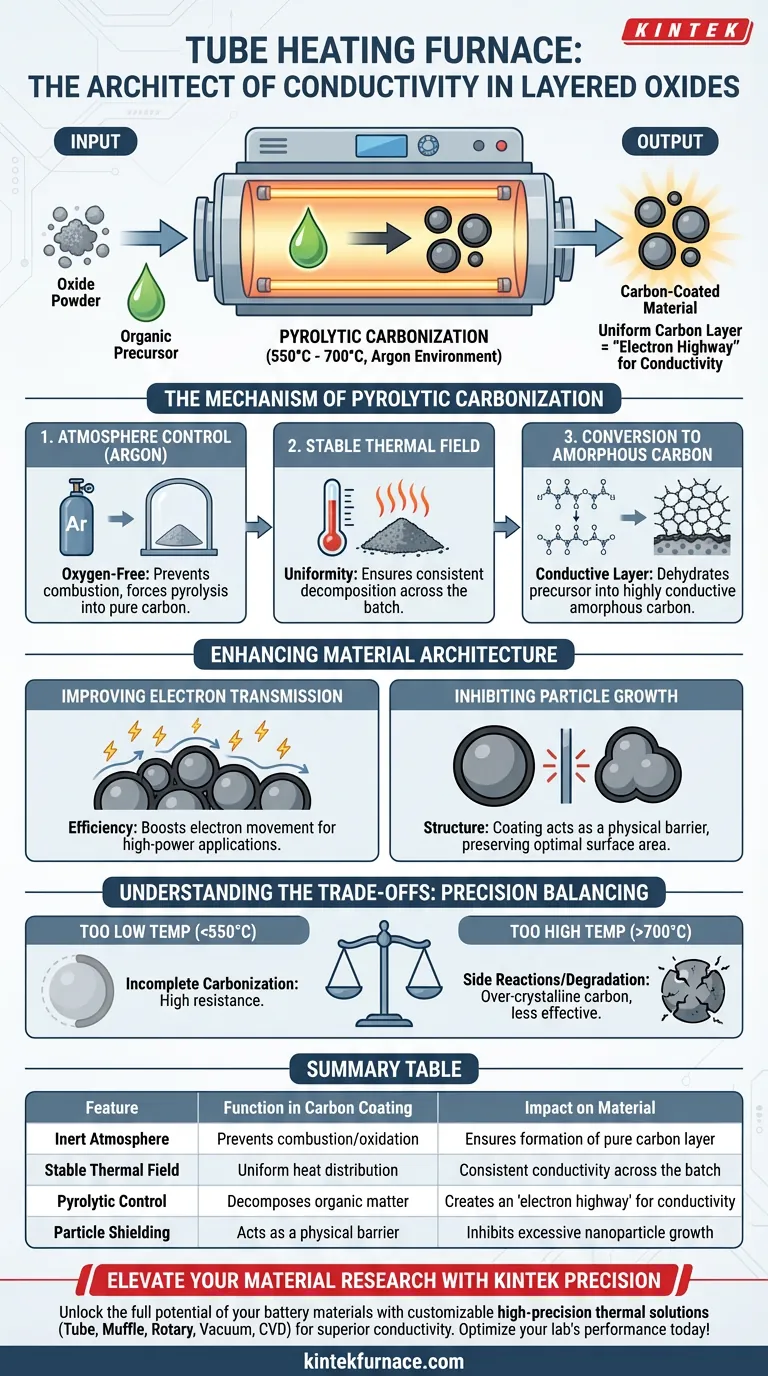

A tube heating furnace serves as the precision reactor required to transform organic precursors into a highly conductive network on cathode materials. It functions by treating oxide powders mixed with organic compounds in a strictly controlled, oxygen-free argon environment at elevated temperatures, typically ranging from 550°C to 700°C. This process facilitates pyrolytic carbonization, resulting in a uniform carbon layer that solves the inherent conductivity limitations of layered oxides.

By maintaining a stable, inert thermal field, the furnace ensures the complete decomposition of organic matter into conductive amorphous carbon. This coating acts as an "electron highway" across the surface of the material, significantly enhancing electron transmission efficiency and the overall rate performance of the battery.

The Mechanism of Pyrolytic Carbonization

Atmosphere Control is Paramount

The primary function of the tube furnace is to generate an oxygen-free environment, typically using Argon gas.

If oxygen were present during heating, the organic precursors would simply burn away as carbon dioxide.

By excluding oxygen, the furnace forces the organic material to undergo pyrolysis, chemically decomposing into pure carbon rather than combusting.

The Role of the Thermal Field

A high-quality tube furnace provides a stable thermal field throughout the heating zone.

This uniformity is critical to ensure that every particle of the powder mixture experiences the exact same conditions.

Without this stability, the decomposition of organic matter (such as sucrose) would be uneven, leading to inconsistent conductivity across the material batch.

Conversion to Amorphous Carbon

Under these specific conditions, the heat drives dehydration and carbonization of the precursor.

This transforms the organic material into highly conductive amorphous carbon.

This new carbon layer bonds directly to the surface of the layered oxide particles, creating a continuous path for electrical current.

Enhancing Material Architecture

Improving Electron Transmission

Layered oxide materials often suffer from poor intrinsic electrical conductivity.

The carbon coating generated by the furnace significantly improves electron transmission efficiency.

This allows electrons to move freely between the active material and the current collector, which is essential for high-power battery applications.

Inhibiting Particle Growth

Beyond conductivity, the carbon coating plays a structural role.

The coating acts as a physical barrier during the heating process, inhibiting the excessive growth of nanoparticles.

This preserves the optimal surface area of the active material, further contributing to improved electrochemical performance.

Understanding the Trade-offs

While the tube furnace is effective, the parameters must be balanced with precision to avoid diminishing returns.

Temperature Sensitivity

If the temperature is too low (e.g., significantly below 550°C), the organic precursor may not fully carbonize.

This results in a coating with high resistance, defeating the purpose of the process.

The Risk of Over-Heating

Conversely, temperatures that are too high can trigger unwanted side reactions between the carbon and the oxide material.

This can degrade the active material itself or lead to overly crystalline carbon, which may be less effective at bridging particles than amorphous carbon.

Making the Right Choice for Your Goal

To maximize the efficacy of your carbon coating process, align your furnace parameters with your specific material requirements.

- If your primary focus is Conductivity: Prioritize higher temperatures (within the safe limit of your oxide) to ensure complete carbonization and the formation of a highly conductive amorphous network.

- If your primary focus is Particle Size Control: Focus on the stability of the thermal field to ensure the carbon coating forms quickly and uniformly, locking in particle size before growth occurs.

The tube furnace is not just a heater; it is the architect of the electron transport network that defines your material's final performance.

Summary Table:

| Feature | Function in Carbon Coating | Impact on Material |

|---|---|---|

| Inert Atmosphere | Prevents combustion/oxidation of precursors | Ensures formation of pure carbon layer |

| Stable Thermal Field | Uniform heat distribution (550°C - 700°C) | Consistent conductivity across the batch |

| Pyrolytic Control | Decomposes organic matter into carbon | Creates an 'electron highway' for conductivity |

| Particle Shielding | Acts as a physical barrier | Inhibits excessive nanoparticle growth |

Elevate Your Material Research with KINTEK Precision

Unlock the full potential of your battery materials with KINTEK’s high-performance thermal solutions. Backed by expert R&D and world-class manufacturing, KINTEK offers high-precision Muffle, Tube, Rotary, Vacuum, and CVD systems—all fully customizable to meet your unique experimental needs.

Whether you are refining pyrolytic carbonization or developing next-generation layered oxides, our furnaces provide the stable thermal fields and rigorous atmosphere control necessary for superior conductivity. Contact us today to optimize your lab's performance!

Visual Guide

References

- Wonseok Ko, Jongsoon Kim. Structural and electrochemical stabilization enabling high‐energy P3‐type Cr‐based layered oxide cathode for K‐ion batteries. DOI: 10.1002/cey2.454

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How does the hydrogen reduction process in a laboratory tube furnace facilitate the exsolution of nickel species?

- Why is a high-temperature tube furnace essential for PPAC activation? Precision Thermal Control for Superior Porosity

- How does a high-temperature tube furnace ensure environmental stability for SOEC? Precision Heat & Atmosphere Control

- What is the function of a tube furnace in the final synthesis stage of C–Ag@ZnO nanocomposites? Key Roles Explained

- How are multi zone tube furnaces applied in biomedical research? Unlock Advanced Biomaterial Engineering

- What is the significance of a multi-zone configuration in a horizontal tube furnace? Master FC-CVD Synthesis Control

- What is the process for using a vacuum tube experimental furnace? Master Precise Control for Your Lab

- Why is uniform heating important in horizontal furnaces? Ensure Material Quality and Process Efficiency