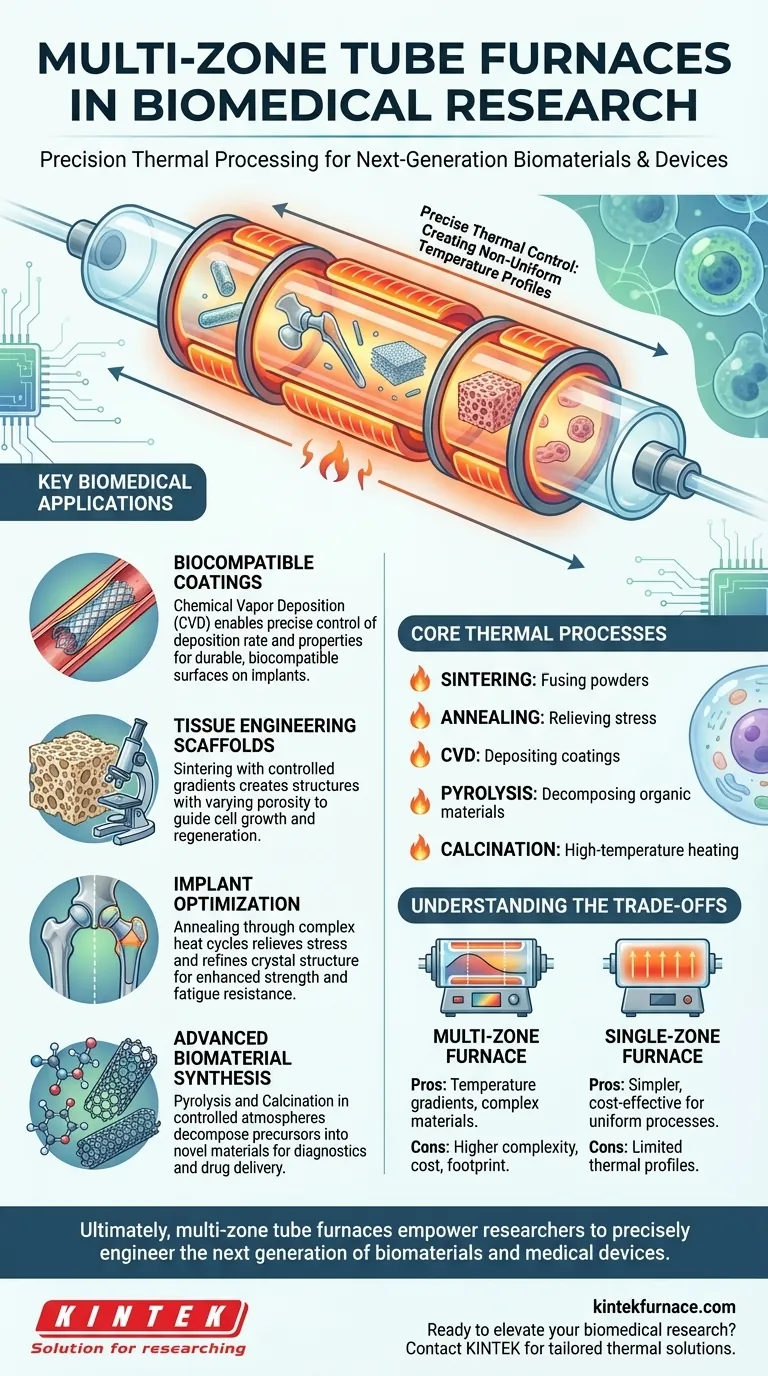

In biomedical research, multi-zone tube furnaces are primarily used to create and refine advanced biomaterials and medical device coatings through highly precise thermal processing. They enable complex procedures like chemical vapor deposition (CVD) for biocompatible films, sintering for tissue scaffolds, and annealing for metallic implants, where controlling temperature gradients is critical for success.

The core value of a multi-zone furnace is its ability to create non-uniform temperature profiles along a sample. This capability is essential for fabricating the functionally sophisticated materials required for next-generation medical devices and tissue engineering applications.

Why Precise Thermal Control is Crucial in Biomedicine

In material science, uniform heating is often the goal. In advanced biomedical research, the ability to create controlled differences in temperature is what enables breakthroughs. This is the fundamental advantage of a multi-zone furnace.

Creating Biocompatible Surfaces and Coatings

Many medical implants, from vascular stents to artificial joints, require special coatings to ensure the body does not reject them. A multi-zone tube furnace provides the perfect environment for this.

The process, often Chemical Vapor Deposition (CVD), involves flowing a precursor gas over the implant at a specific temperature profile. Different zones can be set to different temperatures to precisely control the deposition rate and coating properties along the length of the device, creating a durable and highly biocompatible surface.

Synthesizing Materials for Tissue Engineering

Tissue engineering aims to create scaffolds that mimic natural tissue, encouraging cells to grow and regenerate organs or bone. These scaffolds must often have graded properties, such as varying porosity.

Using a multi-zone furnace, researchers can sinter (heat powders until they fuse) a ceramic or polymer material with a controlled temperature gradient. This allows them to create a single structure that is dense on one end and porous on the other, guiding cell growth in a specific way.

Optimizing the Properties of Medical Implants

The mechanical strength and longevity of a metallic implant, such as a hip replacement, are paramount. Annealing is a heat treatment process that relieves internal stresses and refines the crystal structure of a metal, making it stronger and more resistant to fatigue.

A multi-zone furnace allows for complex annealing cycles, where different parts of an implant can be treated differently to optimize strength where needed while maintaining flexibility elsewhere. This level of control is impossible with a standard single-zone furnace.

Enabling a Range of Key Thermal Processes

Multi-zone tube furnaces are versatile tools that support the core thermal processes used in biomaterial synthesis:

- Sintering: Fusing powders to create solid, often porous, structures like bone scaffolds.

- Annealing: Relieving stress in metallic implants to improve mechanical properties.

- CVD: Depositing thin-film coatings to enhance biocompatibility.

- Pyrolysis: Decomposing organic materials in a controlled atmosphere to create advanced carbon-based biomaterials.

- Calcination: Heating materials to high temperatures to induce phase transitions or remove impurities.

Understanding the Trade-offs

While powerful, a multi-zone furnace is not always the best choice. Understanding its limitations is key to making a sound investment in lab equipment.

Complexity vs. Simplicity

The primary benefit—the ability to create temperature gradients—is also its main source of complexity. Programming, calibrating, and troubleshooting a multi-zone system requires more expertise than operating a simple, uniform-temperature furnace.

Cost and Footprint

Each additional heating zone adds cost and complexity, including more power controllers, thermocouples, and sophisticated software. These systems are more expensive to purchase and maintain than their single-zone counterparts.

When Simpler is Better

If your research involves uniform processes like drying a sample, basic calcination of a powder, or heat-treating a small, homogenous material, a multi-zone furnace is overkill. A more cost-effective single-zone furnace is often the more practical and reliable tool for these tasks.

Making the Right Choice for Your Research

Your specific research goal dictates the thermal process you need, which in turn determines if a multi-zone furnace is necessary.

- If your primary focus is medical device compatibility: You will likely use Chemical Vapor Deposition (CVD) to apply ultra-thin biocompatible coatings.

- If your primary focus is tissue engineering scaffolds: Sintering of biomaterial powders is the key process for creating porous, cell-friendly structures.

- If your primary focus is improving implant durability: Annealing is the critical process to enhance the mechanical strength and lifespan of metallic implants.

- If your primary focus is creating novel carbon nanomaterials: Pyrolysis is used to thermally decompose precursors into new materials for drug delivery or diagnostics.

Ultimately, a multi-zone tube furnace empowers researchers to move beyond simple heating and begin precisely engineering the next generation of biomaterials.

Summary Table:

| Application | Key Process | Benefits |

|---|---|---|

| Biocompatible Coatings | Chemical Vapor Deposition (CVD) | Precise control for durable, non-reject surfaces |

| Tissue Engineering Scaffolds | Sintering | Graded porosity to guide cell growth |

| Medical Implant Optimization | Annealing | Enhanced strength and fatigue resistance |

| Advanced Biomaterial Synthesis | Pyrolysis/Calcination | Creation of novel materials for diagnostics |

Ready to elevate your biomedical research with tailored thermal solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnaces, including multi-zone tube furnaces, muffle furnaces, vacuum & atmosphere furnaces, and CVD/PECVD systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs, whether you're developing biocompatible coatings, tissue scaffolds, or durable implants. Contact us today to discuss how our solutions can drive your innovations forward!

Visual Guide

Related Products

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

People Also Ask

- What are the advantages of individually temperature-controlled zones in multi-zone furnaces? Unlock Precision Thermal Gradients

- How are multi zone tube furnaces used in ceramics, metallurgy and glass research? Unlock Precise Thermal Control for Advanced Materials

- What advantages do multi zone tube furnaces offer for chemical reaction studies? Achieve Precise Thermal Control

- What is the maximum sample size that the 3-Zone tube furnace can accommodate? Optimize for Uniform Heating and CVD

- What are the benefits of integrating multiple heating zones in a tube furnace? Unlock Precise Thermal Control