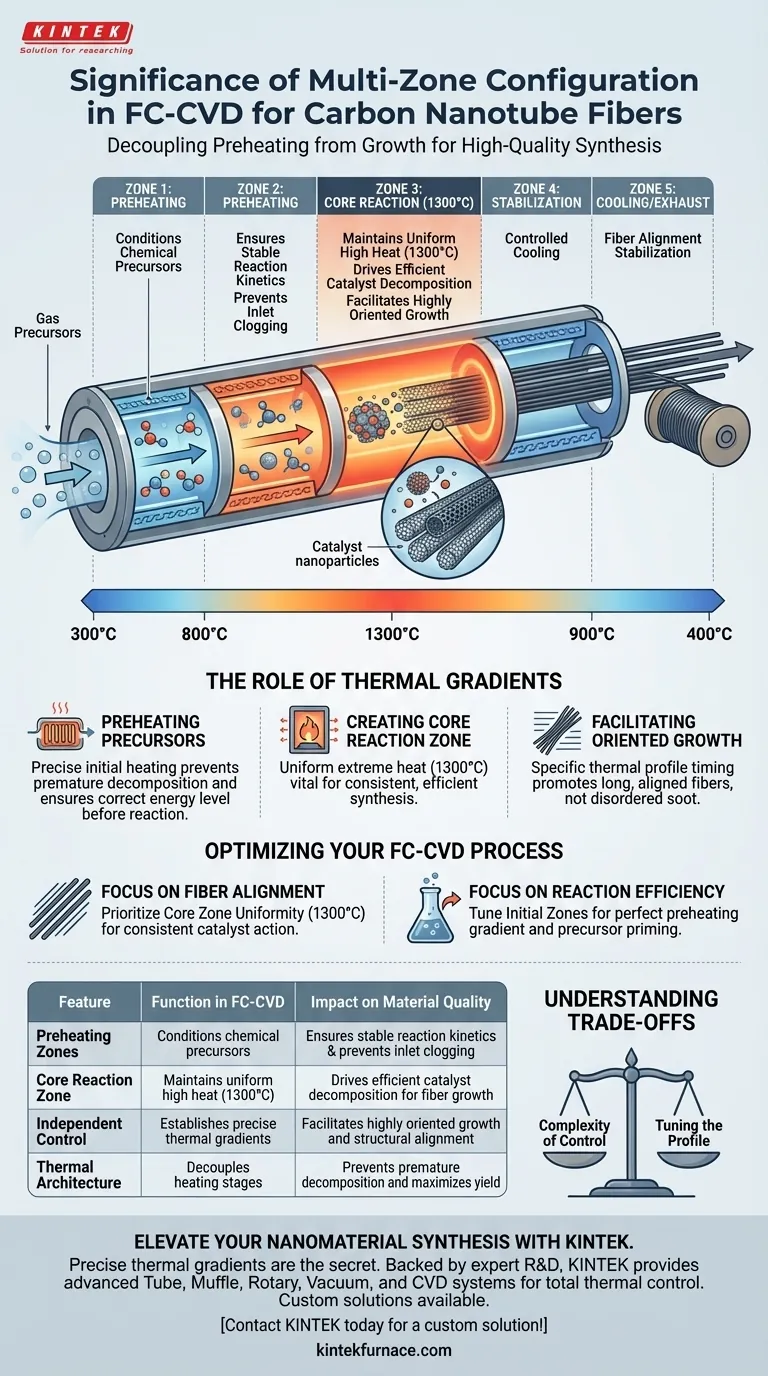

A multi-zone configuration is critical in Floating Catalyst Chemical Vapor Deposition (FC-CVD) because it allows you to decouple the preheating of chemical precursors from the actual growth of the nanomaterials. By utilizing a system with independent heating controls—such as a five-zone furnace—you can establish precise temperature gradients that prepare the reactants before they enter the high-temperature core, ensuring the thermodynamic conditions necessary for high-quality carbon nanotube fiber synthesis.

In FC-CVD, a single uniform temperature across the entire tube is often insufficient for optimal results. A multi-zone furnace provides the thermal architecture required to preheat precursors separately from the reaction zone, maintaining a stable thermal field that drives efficient catalyst decomposition and highly oriented nanotube growth.

The Role of Thermal Gradients

Preheating the Precursors

The primary function of the initial zones in a multi-zone furnace is to condition the reactants. Before reaching the central reaction chamber, precursors must be adequately preheated.

This early stage ensures that the gas mixture is at the correct thermal energy level before the chemical breakdown begins. Without this gradient, precursors might enter the core zone too cold, disrupting the reaction kinetics.

Creating the Core Reaction Zone

The central zones of the furnace are designed to maintain a highly uniform thermal field at extreme temperatures, often reaching 1300 °C.

This high-heat environment is where the actual synthesis occurs. The uniformity provided by independent zone control ensures that the temperature does not fluctuate across the length of the growth zone, which is vital for consistency.

Facilitating Oriented Growth

The specific arrangement of temperature zones directly impacts the structural quality of the output.

By controlling the thermal profile, you promote efficient catalyst decomposition at the exact right moment. This precise timing facilitates the oriented growth of carbon nanotubes, allowing them to form long, aligned fibers rather than disordered soot.

Understanding the Trade-offs

Complexity of Control

While a multi-zone system offers superior precision, it introduces significant operational complexity. Managing a five-zone system requires sophisticated controllers to ensure that the interaction between zones does not create unwanted thermal turbulence.

Tuning the Profile

Achieving the perfect gradient is not automatic. The operator must empirically determine the correct setpoints for each zone to balance preheating with the peak reaction temperature. Incorrect settings in the early zones can lead to premature decomposition of the catalyst, clogging the inlet or reducing yield in the main chamber.

Optimizing Your FC-CVD Process

To maximize the potential of a horizontal tube furnace, you must tailor your thermal profile to your specific synthesis goals.

- If your primary focus is Fiber Alignment: Prioritize the uniformity of the central high-temperature zones (1300 °C) to ensure the catalyst acts consistently during the growth phase.

- If your primary focus is Reaction Efficiency: Focus on tuning the initial zones to perfect the preheating gradient, ensuring precursors are fully primed before they hit the reaction zone.

Success in FC-CVD relies not just on reaching high temperatures, but on controlling exactly where and how that heat is applied along the tube.

Summary Table:

| Feature | Function in FC-CVD | Impact on Material Quality |

|---|---|---|

| Preheating Zones | Conditions chemical precursors | Ensures stable reaction kinetics & prevents inlet clogging |

| Core Reaction Zone | Maintains uniform high heat (1300°C) | Drives efficient catalyst decomposition for fiber growth |

| Independent Control | Establishes precise thermal gradients | Facilitates highly oriented growth and structural alignment |

| Thermal Architecture | Decouples heating stages | Prevents premature decomposition and maximizes yield |

Elevate Your Nanomaterial Synthesis with KINTEK

Precise thermal gradients are the secret to high-performance carbon nanotube fibers. Backed by expert R&D and world-class manufacturing, KINTEK provides advanced Tube, Muffle, Rotary, Vacuum, and CVD systems designed to give you total control over your thermal architecture. Whether you need a standard five-zone configuration or a fully customizable high-temp furnace tailored to your unique research needs, our engineering team is here to help you achieve the perfect thermal profile.

Ready to optimize your FC-CVD process? Contact KINTEK today for a custom solution!

Visual Guide

References

- Rajath Alexander, Kinshuk Dasgupta. Open-atmosphere spinning of carbon nanotube fibers sans hydrogen flow by floating catalyst chemical vapor deposition: an insight into the mechanism. DOI: 10.1007/s42823-024-00843-w

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- How does a CVD tube furnace achieve high purity in gate media preparation? Master Precision Control for Flawless Films

- What are the practical applications of gate media prepared by CVD tube furnaces? Unlock Advanced Electronics and More

- What are the key features of CVD tube furnaces for 2D material processing? Unlock Precision Synthesis for Superior Materials

- How are hexagonal boron nitride (h-BN) films processed using CVD tube furnaces? Optimize Growth for High-Quality 2D Materials

- What are the key design features of a CVD Tube Furnace? Optimize Your Material Synthesis with Precision