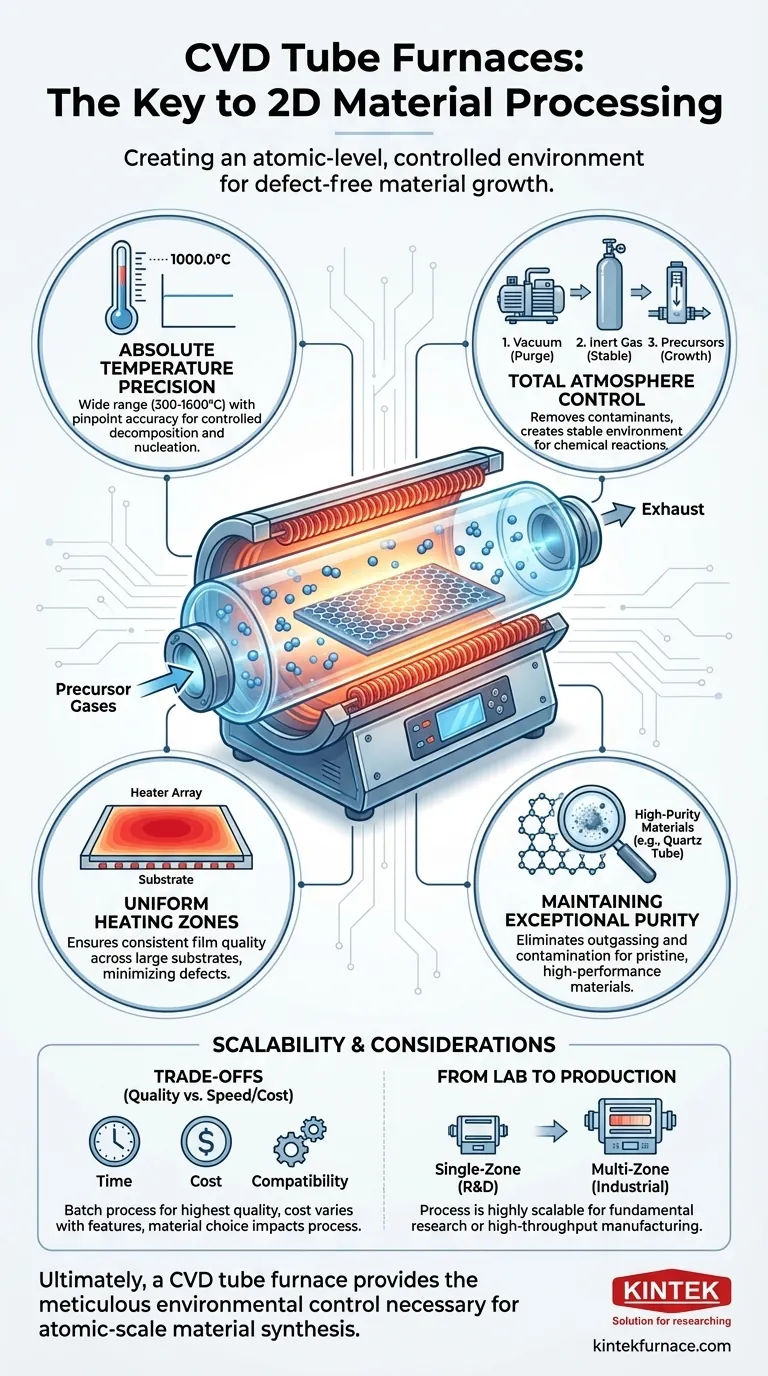

At its core, a Chemical Vapor Deposition (CVD) tube furnace is suitable for 2D material processing because it provides a highly controlled environment. Its key features—precise temperature control, managed atmospheres, uniform heating zones, and high purity—are essential for the atomic-level construction required to synthesize and sinter high-quality, defect-free materials like graphene and transition metal dichalcogenides (TMDs).

Synthesizing a material that is only one atom thick is a feat of precision engineering. A CVD tube furnace is not merely a heater; it is a self-contained, high-purity reactor that gives researchers the dials to control the fundamental parameters of atomic-scale growth: temperature, pressure, and chemical composition.

Why a Precision Environment is Non-Negotiable

The defining properties of 2D materials emerge directly from their flawless, single-layer atomic structure. Any deviation, such as a structural defect, impurity, or variation in thickness, can dramatically degrade their electronic and mechanical performance.

A CVD furnace is designed to create an almost perfect world for material growth. It systematically eliminates the variables and contaminants that would otherwise prevent the formation of a uniform, crystalline monolayer on a substrate.

Deconstructing the Core Capabilities

Each feature of a CVD furnace directly addresses a critical requirement for successful 2D material synthesis.

Absolute Temperature Precision and Uniformity

The synthesis of 2D materials is a temperature-sensitive process. Specific temperatures trigger the decomposition of precursor gases, the nucleation of crystals on the substrate, and the lateral growth of those crystals into a continuous film.

CVD furnaces provide a wide operational range, often from 300°C to 1600°C, with pinpoint accuracy. Powerful all-round heaters and high-grade alumina fiber insulation ensure the target temperature is not only reached but also held uniformly across the entire sample, which is vital for creating large, consistent films.

Total Atmosphere Control

Atmosphere control is arguably the most critical function. The furnace tube can be configured for three distinct atmospheric conditions, each playing a crucial role.

- Vacuum: A high vacuum is first used to purge the chamber of air and water vapor, removing potential contaminants that could react with the materials and cause defects.

- Inert Gas: The system is then filled with an inert gas, such as argon, to create a stable, non-reactive environment at a specific pressure.

- Precursor Gases: Finally, one or more precursor gases (the chemical "building blocks" of the 2D material) are introduced at a precisely controlled flow rate to initiate the deposition process.

Maintaining Exceptional Purity

At the atomic scale, even a single speck of dust is a massive contaminant. CVD furnaces are built with high-purity materials, most commonly a quartz tube, to minimize outgassing and contamination during high-temperature operation.

This ensures the resulting 2D film is composed only of the intended elements, preserving its intrinsic properties. This purity is essential for high-performance applications in semiconductors and electronics, such as the gate media in advanced transistors.

Scalability From Lab to Production

The principles of CVD are highly scalable. While laboratory research often uses small, single-zone furnaces, the same process can be implemented in larger, multi-zone systems.

These advanced furnaces can process larger substrates or even enable continuous material processing, making CVD a viable method for both fundamental research and industrial-scale manufacturing of 2D materials.

Understanding the Trade-offs

While indispensable, CVD tube furnace systems are not without their operational considerations.

Process Time vs. Quality

CVD is a batch or semi-batch process that prioritizes quality and control over speed. The time required for pumping down, heating, deposition, and cooling can be significant. This deliberate pace is a trade-off for achieving the highest-quality, most uniform films, which is often a non-negotiable requirement for 2D materials.

Cost vs. Capability

The cost of a CVD furnace system correlates directly with its capabilities. Features like higher maximum temperature, better vacuum performance (lower base pressure), more sophisticated gas mixing systems, and larger uniform heating zones all add to the expense. A system for basic graphene growth will be far less complex than one designed for novel, multi-element heterostructures.

Material and Substrate Compatibility

The choice of tube material (e.g., quartz vs. alumina) can impact the maximum process temperature and potential for contamination. Similarly, the process parameters must be carefully tuned for the specific substrate being used, as the substrate itself plays an active role in catalyzing the growth of the 2D material.

Making the Right Choice for Your Goal

The ideal CVD furnace configuration depends entirely on your specific objective.

- If your primary focus is fundamental research on novel materials: Prioritize a versatile system with a wide temperature range and precise control over multiple gas inputs to explore new synthesis recipes.

- If your primary focus is producing large-area, high-quality graphene: Invest in a furnace with a large-diameter tube, an extended uniform heating zone, and excellent vacuum capabilities to minimize defects.

- If your primary focus is scaling up for industrial application: Look for multi-zone furnaces or rotary systems designed for higher throughput, process automation, and absolute repeatability.

Ultimately, a CVD tube furnace provides the meticulous environmental control necessary to transform gaseous precursors into perfectly structured, atom-thick materials.

Summary Table:

| Feature | Benefit for 2D Material Processing |

|---|---|

| Precise Temperature Control | Enables accurate decomposition and growth for uniform, defect-free films |

| Managed Atmospheres | Allows vacuum, inert gas, and precursor control to prevent contamination |

| Uniform Heating Zones | Ensures consistent film quality across large substrates |

| High Purity Materials | Minimizes impurities for superior electronic and mechanical properties |

| Scalability | Supports both lab research and industrial production with multi-zone systems |

Ready to elevate your 2D material synthesis? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including CVD/PECVD Systems, Muffle, Tube, Rotary Furnaces, and Vacuum & Atmosphere Furnaces, is complemented by strong deep customization capability to precisely meet your unique experimental requirements. Contact us today to discuss how our tailored solutions can enhance your research and production outcomes!

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How does Chemical Vapor Deposition (CVD) work? Master Thin Film Fabrication for Superior Materials

- What role does a Chemical Vapor Deposition (CVD) system play in 2D material synthesis? Master Scalable Material Growth

- What is Chemical Vapor Deposition (CVD) and where is it commonly used? Key Applications and Benefits

- What are the main challenges in CVD technology? Overcome Key Hurdles for Better Thin-Film Deposition

- What is the function of a Low-Pressure Chemical Vapor Deposition (LPCVD) system in the synthesis of hBN thin films?

- Why is diluted H2S gas preferred over solid sulfur for MoS2/WS2 synthesis? Precision CVD Control and Uniformity

- What biomedical applications do CVD furnaces have? Enhance Implant Safety and Drug Delivery

- What advanced materials can be produced using CVD? Explore High-Performance Coatings and Nanostructures