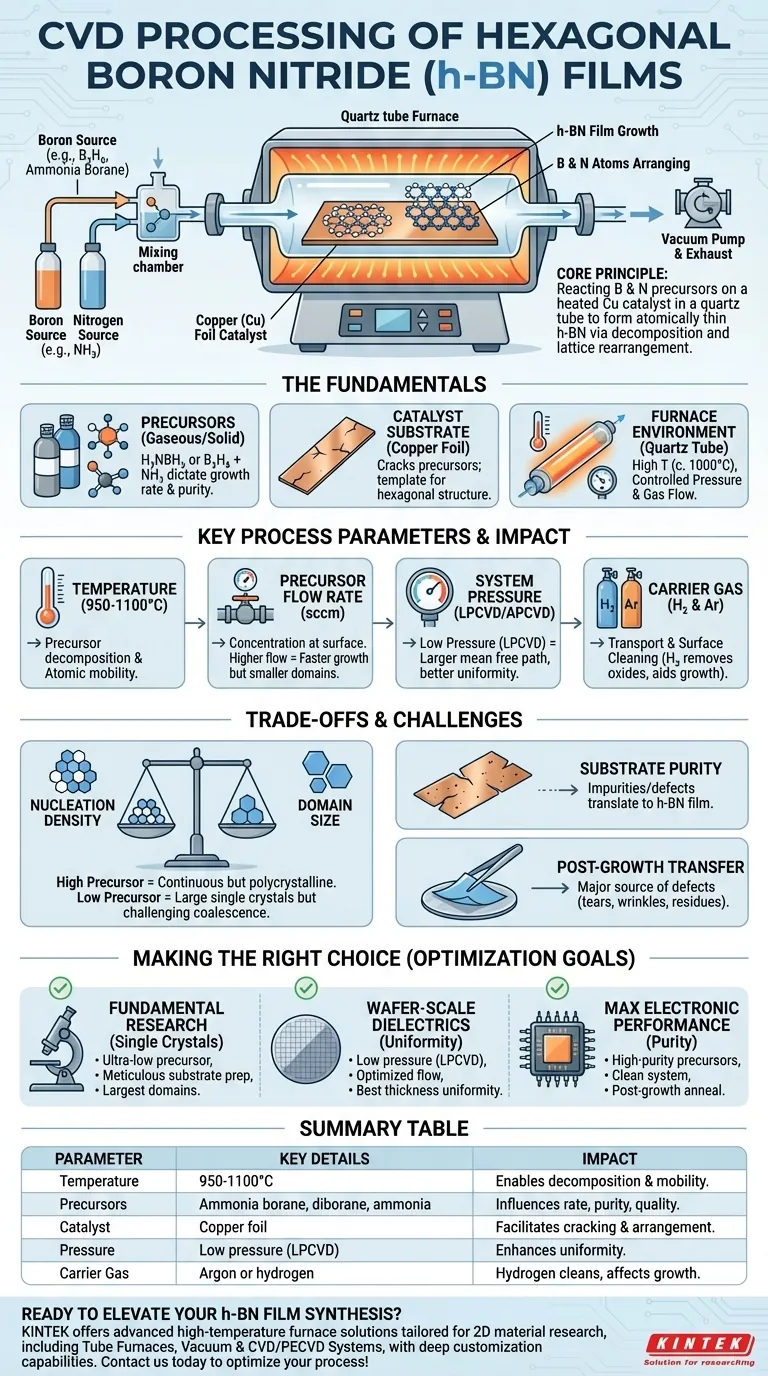

At its core, processing hexagonal boron nitride (h-BN) films via Chemical Vapor Deposition (CVD) involves reacting specific boron and nitrogen precursor gases on a heated catalyst surface, typically copper foil, inside a quartz tube furnace. The high temperature provides the necessary energy to decompose the precursors and allows the resulting boron and nitrogen atoms to arrange themselves into the characteristic hexagonal lattice on the catalyst surface, forming a high-quality, atomically thin film.

The central challenge in h-BN synthesis is not merely mixing gases at high temperatures. It is the precise, multi-variable control over the reaction environment to dictate how atomic layers nucleate and grow, balancing the competing goals of crystal size, film uniformity, and defect density.

The Fundamentals of the CVD Process

Chemical Vapor Deposition is a bottom-up material synthesis technique. For h-BN, it means building the film one atom at a time from gaseous ingredients, or "precursors." The tube furnace provides the highly controlled environment required for this atomic-scale construction.

The Core Reaction and Precursors

The process relies on delivering both a boron source and a nitrogen source to the heated substrate. The choice of precursor is critical as it influences the deposition temperature, growth rate, and purity of the final film.

Common precursors include ammonia borane (H₃NBH₃), a solid that provides both B and N in a single molecule, or separate gas sources like diborane (B₂H₆) for boron and ammonia (NH₃) for nitrogen.

The Role of the Catalyst Substrate

h-BN does not readily form on just any surface. A metallic catalyst, most commonly copper (Cu) foil, is used to facilitate the reaction.

The catalyst serves two functions: it catalytically "cracks" or decomposes the precursor molecules at its surface, and it provides a template for the B and N atoms to arrange themselves into the desired low-energy hexagonal structure.

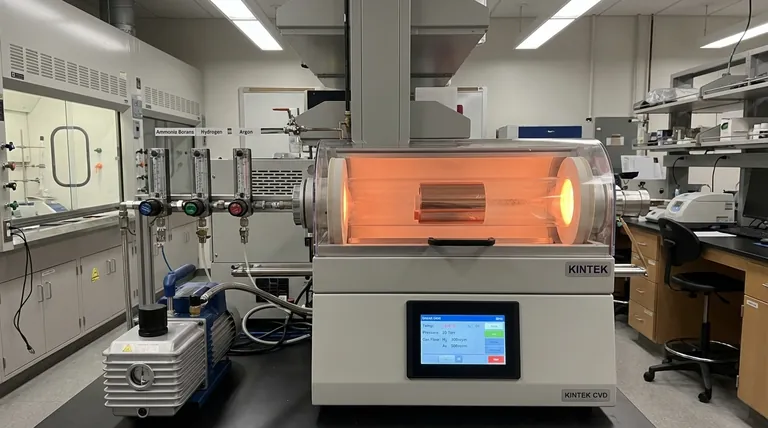

The Furnace Environment

A standard CVD setup consists of a quartz tube that can be heated to very high temperatures (often around 1000°C for h-BN). This tube is connected to a system of gas lines for introducing precursors and carrier gases, as well as a vacuum pump for controlling the system pressure.

Key Process Parameters and Their Impact

The quality of the final h-BN film is a direct result of carefully tuning several interconnected process variables. A small change in one parameter can have a significant effect on the outcome.

Temperature Control

Temperature is the primary driver of the CVD reaction. It must be high enough (typically 950-1100°C) to provide the thermal energy needed for precursor decomposition and for the atoms to have enough mobility to diffuse across the catalyst surface and find their ideal lattice sites.

Precursor Flow Rate

The rate at which precursor gases are introduced, measured in standard cubic centimeters per minute (sccm), directly controls the concentration of reactants available at the substrate surface.

A higher flow rate can increase the growth speed but may also lead to a higher density of nucleation sites, resulting in smaller individual crystal domains and a more polycrystalline film.

System Pressure

The process can be run at atmospheric pressure (APCVD) or, more commonly, at low pressure (LPCVD). Pressure affects the mean free path of gas molecules.

Low pressure increases the mean free path, leading to more uniform film deposition over large areas. It helps ensure the precursor molecules reach the entire substrate surface evenly rather than depleting near the gas inlet.

Carrier Gas and Growth Atmosphere

Inert gases like argon (Ar) or reducing gases like hydrogen (H₂) are used to transport the precursor vapor into the furnace.

Hydrogen is particularly important as it helps keep the copper catalyst surface clean and free of oxides, which would otherwise inhibit or disrupt h-BN growth. The ratio of H₂ to other gases can significantly alter the growth dynamics.

Understanding the Trade-offs and Challenges

Synthesizing perfect h-BN is a complex balancing act. Optimizing for one property often comes at the expense of another.

Nucleation Density vs. Domain Size

This is the classic trade-off in 2D material growth. Using a high concentration of precursor leads to many nucleation sites, quickly forming a continuous film. However, this film will be made of many small, stitched-together crystals with performance-limiting grain boundaries.

To grow large, single-crystal domains, researchers use very low precursor concentrations to minimize nucleation sites. This allows individual "flakes" to grow very large before they touch, but it becomes challenging to merge them into a continuous, defect-free film.

Substrate Purity and Preparation

The quality of the h-BN film can be no better than the substrate it is grown on. Any impurities, wrinkles, or crystal defects on the copper foil will be translated into defects in the h-BN film.

For this reason, significant effort is spent on pre-treating the catalyst, often involving electropolishing to create an ultra-smooth surface and a high-temperature anneal in a hydrogen atmosphere to remove oxides and re-structure the copper grains.

The Post-Growth Transfer Process

Once grown on the metal catalyst, the atomically thin h-BN film must be transferred to a functional substrate (e.g., a silicon wafer) for device fabrication. This mechanical and chemical process is a major source of defects.

The transfer step can introduce tears, wrinkles, folds, and chemical residues, all of which can compromise the dielectric properties and structural integrity of the film.

Making the Right Choice for Your Goal

The optimal CVD parameters depend entirely on the intended application of the h-BN film.

- If your primary focus is fundamental research on single crystals: Prioritize ultra-low precursor concentrations and meticulously prepared substrates to grow the largest possible individual domains.

- If your primary focus is wafer-scale dielectric layers: Emphasize low-pressure conditions and optimized gas flow dynamics to achieve the best possible thickness uniformity across the entire substrate.

- If your primary focus is maximum electronic performance: Concentrate on using high-purity precursors and a clean growth system, followed by a post-growth anneal to minimize trapped impurities and point defects in the film.

Mastering the interplay of these fundamental principles is the key to reliably producing high-quality h-BN tailored for the next generation of 2D material-based technologies.

Summary Table:

| Process Parameter | Key Details | Impact on h-BN Film |

|---|---|---|

| Temperature | 950-1100°C range | Enables precursor decomposition and atomic mobility for lattice formation |

| Precursors | Ammonia borane, diborane, ammonia | Influences deposition rate, purity, and crystal quality |

| Catalyst | Copper foil | Facilitates precursor cracking and hexagonal lattice arrangement |

| Pressure | Low pressure (LPCVD) preferred | Enhances uniformity by increasing gas mean free path |

| Carrier Gas | Argon or hydrogen | Hydrogen cleans catalyst, affecting growth dynamics and defect reduction |

Ready to elevate your h-BN film synthesis? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for 2D material research. Our product line, including Tube Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental needs—whether for wafer-scale uniformity, single-crystal growth, or electronic performance. Contact us today to discuss how our expertise can optimize your CVD processes and accelerate your innovations!

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How does CVD tube furnace sintering enhance graphene growth? Achieve Superior Crystallinity and High Electron Mobility

- What temperature range do standard CVD tube furnaces operate at? Unlock Precision for Your Material Deposition

- What are the key features of CVD tube-furnace systems? Unlock Precise Thin-Film Deposition

- How does the gas control system in a CVD tube furnace enhance its functionality? Achieve Precise Thin Film Deposition

- What is a common subtype of CVD furnace and how does it function? Discover the CVD Tube Furnace for Uniform Thin Films