At its core, a Chemical Vapor Deposition (CVD) tube furnace achieves exceptional purity by creating an isolated, ultra-clean environment where a highly specific chemical reaction can take place. By first removing all atmospheric contaminants via a vacuum and then introducing precise, high-purity reactant gases, the high-temperature process ensures that only the desired atoms break away from their carrier molecules and deposit onto the substrate, forming a film of unparalleled purity.

The fundamental principle behind CVD purity is rigorous exclusion. By creating a controlled vacuum environment and using selective chemical reactions, the process is designed to systematically eliminate contaminants and allow only the essential elements to form the final gate dielectric film.

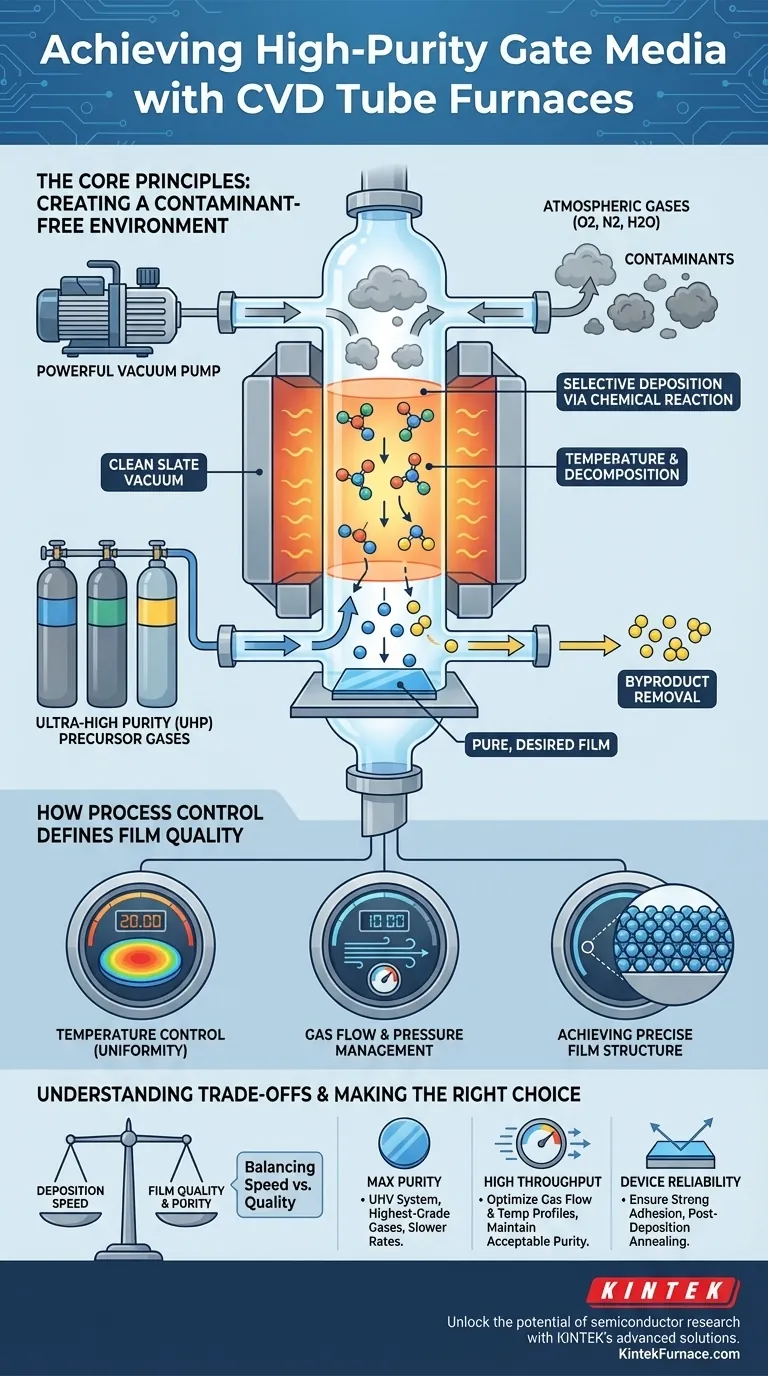

The Core Principles of CVD Purity

To understand how a CVD furnace produces high-purity gate media, you must first grasp the two pillars on which the process is built: creating a perfect environment and then initiating a perfect reaction.

Creating a Contaminant-Free Environment

The first step is to remove anything that doesn't belong. The furnace chamber is sealed and evacuated to a high vacuum, purging atmospheric gases like oxygen, nitrogen, and water vapor.

This step is critical because these ambient gases can react with the substrate or precursor materials, leading to unwanted oxides or nitrides that contaminate the final film and compromise device performance. The vacuum effectively creates a clean slate.

The Role of High-Purity Precursor Gases

With the chamber free of contaminants, specific reactant gases, known as precursors, are introduced. The purity of these gases is paramount.

If the precursors themselves contain impurities, those impurities will inevitably be incorporated into the final film. Therefore, using ultra-high purity (UHP) grade gases is non-negotiable for producing high-quality gate dielectrics.

Selective Deposition via Chemical Reaction

Inside the heated chamber, the high temperature provides the necessary energy to break the chemical bonds within the precursor gas molecules. This process, known as decomposition or pyrolysis, is highly selective.

The temperature is carefully calibrated to target specific bonds, releasing the desired atoms (e.g., silicon from silane) while the unwanted byproducts remain in a gaseous state. These byproducts are then continuously removed from the chamber by the vacuum system, leaving only the pure, intended material deposited on the substrate surface.

How Process Control Defines Film Quality

Achieving purity isn't just about the right ingredients; it's about masterful control over the entire process. The furnace's sophisticated control systems are what guarantee the quality and repeatability of the film.

Temperature as the Reaction Driver

Temperature is the primary lever for controlling the reaction. It must be high enough to provide the activation energy for the desired chemical reaction but not so high that it causes unwanted side reactions or damages the substrate.

Furthermore, temperature uniformity across the entire substrate is essential. Any cold spots can lead to slower deposition and thinner films, while hot spots can cause defects, compromising the integrity of the gate media.

Gas Flow and Pressure Management

The rate at which precursor gases are introduced and the overall pressure within the chamber directly influence the film's properties.

Higher flow rates can increase the deposition speed, but they must be managed carefully to ensure a uniform concentration of reactants across the wafer. The pressure affects the mean free path of gas molecules, which in turn impacts the conformity and density of the deposited film.

Achieving Precise Film Structure

By precisely controlling these parameters—temperature, pressure, and gas flow—engineers can dictate the exact thickness, chemical composition, and crystal structure of the resulting film. This level of control ensures good bonding force to the substrate, enhancing the final device's stability and electrical reliability.

Understanding the Trade-offs and Pitfalls

While highly effective, the CVD process is not without its challenges. Understanding these potential issues is key to successful implementation.

The Constant Risk of Contamination

Even with high-vacuum systems, microscopic leaks or the outgassing of materials from the chamber walls can introduce contaminants. Diligent system maintenance and the use of high-quality components are crucial to mitigate this risk.

The Challenge of Uniformity

Achieving perfect temperature and gas flow uniformity, especially over large substrates or multiple wafers, is a significant engineering challenge. Non-uniformity leads to variations in film thickness and electrical properties across the device.

Balancing Deposition Rate and Quality

There is often a direct trade-off between the speed of deposition and the quality of the film. Rushing the process by increasing temperature or gas flow can lead to the incorporation of defects or the formation of a less dense, more porous film with inferior dielectric properties.

Making the Right Choice for Your Goal

The optimal CVD process parameters depend entirely on your primary objective.

- If your primary focus is maximum purity and film quality: Prioritize the use of an ultra-high vacuum (UHV) system, the highest-grade precursor gases, and slower, more controlled deposition rates.

- If your primary focus is high throughput for production: Concentrate on optimizing gas flow dynamics and temperature profiles to achieve uniform deposition across multiple wafers simultaneously, while finding a balance that maintains acceptable purity.

- If your primary focus is device reliability and stability: Emphasize process controls that ensure strong film adhesion and consider post-deposition annealing steps to improve film density and reduce internal stress.

By mastering these principles of environmental control and chemical precision, you transform the CVD process from a deposition technique into a powerful tool for fabricating flawless semiconductor components.

Summary Table:

| Key Factor | Role in Achieving High Purity |

|---|---|

| Vacuum Environment | Removes atmospheric contaminants like oxygen and water vapor to create a clean slate for reactions |

| High-Purity Precursor Gases | Uses ultra-high purity gases to prevent impurity incorporation into the film |

| Temperature Control | Provides activation energy for selective decomposition and ensures uniform deposition |

| Gas Flow and Pressure Management | Influences deposition uniformity and film density by controlling reactant concentration |

| Process Parameter Optimization | Balances deposition rate, purity, and uniformity for specific goals like quality or throughput |

Unlock the full potential of your semiconductor research with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with precision-engineered products like CVD/PECVD Systems, Tube Furnaces, and more. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements for high-purity gate media preparation. Contact us today to discuss how our solutions can enhance your process control and film quality!

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What temperature range do standard CVD tube furnaces operate at? Unlock Precision for Your Material Deposition

- What customization options are available for CVD tube furnaces? Tailor Your System for Superior Material Synthesis

- How can integrating CVD tube furnaces with other technologies benefit device fabrication? Unlock Advanced Hybrid Processes

- What is a common subtype of CVD furnace and how does it function? Discover the CVD Tube Furnace for Uniform Thin Films

- What is tube CVD? A Guide to High-Purity Thin Film Synthesis