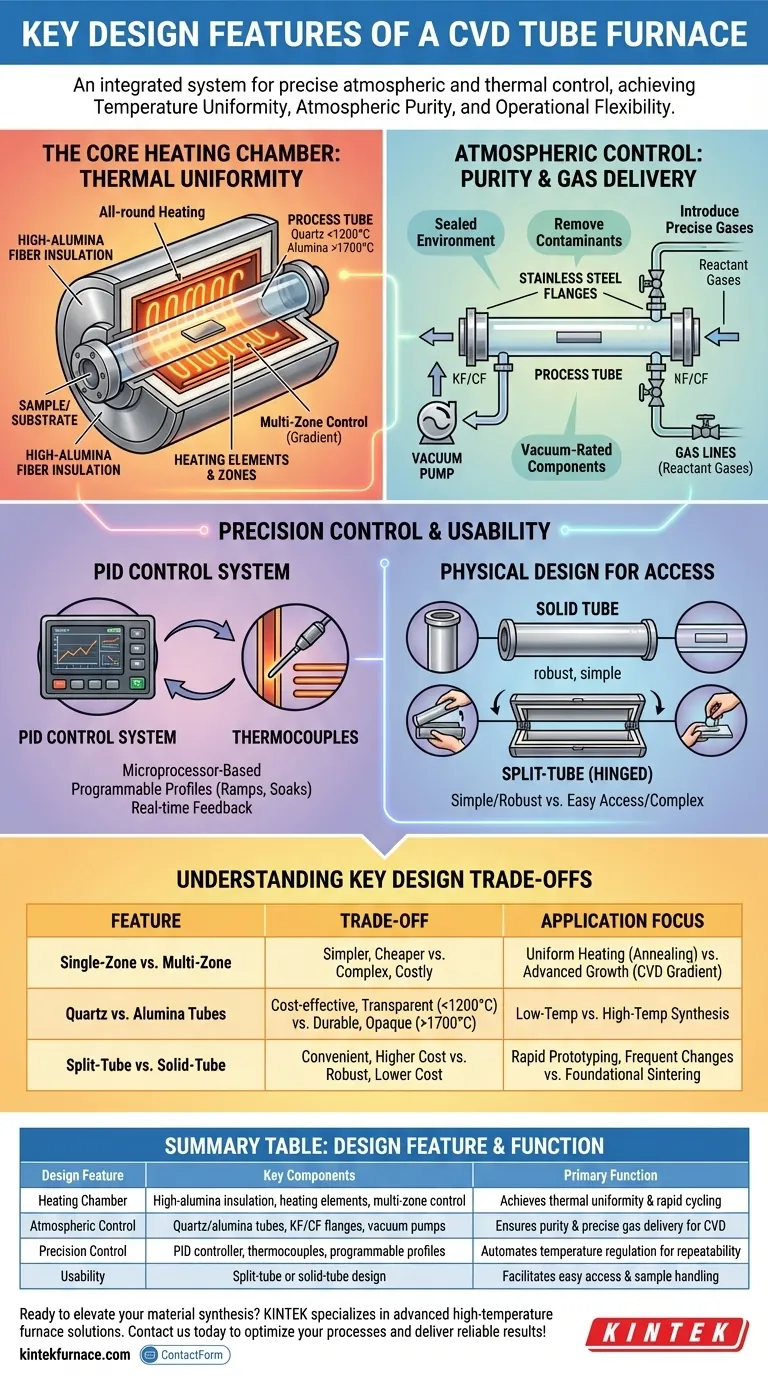

At its core, a Chemical Vapor Deposition (CVD) tube furnace is an integrated system designed for precise atmospheric and thermal control. Its essential design features include a central heating chamber housing a process tube, a sophisticated PID control system for temperature regulation, and a gas and vacuum delivery system with sealed flanges. These components work in concert to create a highly controlled environment for material synthesis.

The design of a CVD furnace is a deliberate balance between three critical goals: achieving absolute temperature uniformity, ensuring exceptional atmospheric purity, and providing operational flexibility. Understanding how each component serves these goals is more important than simply knowing the parts list.

The Core Heating Chamber: Achieving Thermal Uniformity

The primary function of the furnace body is to generate and sustain a stable, uniform thermal environment. The design of this chamber is critical for process repeatability and the quality of the final material.

Furnace Body and Insulation

The furnace chamber is typically a cylindrical or semi-cylindrical shell lined with high-alumina fiber insulation. This material offers excellent thermal resistance and low thermal mass, which enables rapid heating and cooling cycles while minimizing energy consumption.

Heating Elements and Zones

Powerful heating elements are positioned around the chamber to provide all-round heating. In basic furnaces, this may be a single "zone" of control. More advanced systems feature multi-zone control, where several independent sets of heaters and sensors allow for the creation of precise temperature gradients along the length of the tube, a crucial capability for many advanced CVD processes.

Process Tube Materials

The material sample or substrate is placed inside a separate process tube. The choice of tube material depends on the required temperature and chemical environment.

- Quartz tubes are common for processes below 1200°C due to their high purity and transparency, but they are susceptible to thermal shock.

- Alumina tubes are used for higher temperatures (up to 1700°C or more) and offer excellent durability and chemical resistance.

Atmospheric Control: The Foundation of CVD

A CVD furnace is distinguished from a standard tube furnace by its sophisticated control over the internal atmosphere. This is where the "Chemical Vapor Deposition" process actually occurs.

Vacuum and Gas Delivery

The process tube is sealed on both ends with stainless steel KF or CF flanges. These flanges provide ports for connecting a vacuum pump and one or more gas lines. This system allows operators to first evacuate the tube to remove contaminants and then introduce precise reactant gases required for deposition.

Sealing and Purity

The integrity of the flanges and seals is paramount. A perfect seal ensures that no oxygen or moisture from the ambient air can leak into the process chamber, which would contaminate the reaction and ruin the material. This is why high-quality, vacuum-rated components are non-negotiable.

Precision Control and Usability

The furnace's "brain" and its physical ergonomics dictate its performance and ease of use. These systems translate an experimental plan into a precise, repeatable physical process.

The PID Control System

Modern CVD furnaces are governed by a microprocessor-based PID (Proportional-Integral-Derivative) controller. This fully programmable system allows users to define precise heating rates (ramps), hold times (soaks), and cooling profiles. It is the key to process automation and consistency.

Temperature Sensing

High-resolution thermocouples are placed near the heating elements and sometimes inside the process tube. They provide real-time temperature feedback to the PID controller, which continuously adjusts power to the heating elements to precisely match the desired temperature profile.

Physical Design for Access

Furnaces come in two primary physical configurations. A standard solid tube is simple and robust. A split-tube furnace, which is hinged to open lengthwise, provides much easier access to the process tube, simplifying the loading and unloading of complex experimental setups.

Understanding Key Design Trade-offs

Choosing or specifying a CVD furnace involves balancing performance requirements with budget and usability. No single design is perfect for every application.

Single-Zone vs. Multi-Zone Control

A single-zone furnace is simpler, less expensive, and perfectly adequate for processes requiring a uniform hot zone, like annealing. However, it cannot create a temperature gradient. Multi-zone control is more complex and costly but is essential for advanced growth processes where reactants must be heated to different temperatures at different points in the tube.

Quartz vs. Alumina Tubes

The choice is a direct trade-off between maximum operating temperature and cost. Quartz is a cost-effective solution for lower-temperature applications. Alumina is required for high-temperature synthesis but is more expensive and opaque, preventing visual inspection during the process.

Split-Tube vs. Solid-Tube Design

A split-tube design offers tremendous convenience for researchers who frequently change their experimental setup. This accessibility, however, comes at a higher initial cost and introduces more mechanical complexity compared to a robust, solid-tube furnace.

Selecting the Right Furnace for Your Application

Your final choice should be guided by your specific experimental or production goals.

- If your primary focus is foundational material annealing or sintering: A single-zone furnace with a high-purity alumina tube provides a robust and cost-effective solution for uniform heating.

- If your primary focus is advanced thin-film growth (CVD): Prioritize a multi-zone furnace with excellent vacuum sealing and a programmable PID controller for precise gradient and atmospheric control.

- If your primary focus is rapid prototyping and frequent sample changes: A split-tube design will significantly improve your workflow efficiency and reduce downtime between experiments.

Ultimately, understanding how these design features serve your specific process goals is the key to mastering high-temperature material synthesis.

Summary Table:

| Design Feature | Key Components | Primary Function |

|---|---|---|

| Heating Chamber | High-alumina insulation, heating elements, multi-zone control | Achieves thermal uniformity and rapid cycling |

| Atmospheric Control | Quartz/alumina tubes, KF/CF flanges, vacuum pumps | Ensures purity and precise gas delivery for CVD |

| Precision Control | PID controller, thermocouples, programmable profiles | Automates temperature regulation for repeatability |

| Usability | Split-tube or solid-tube design | Facilitates easy access and sample handling |

Ready to elevate your material synthesis? KINTEK specializes in advanced high-temperature furnace solutions tailored for diverse laboratories. Leveraging our exceptional R&D and in-house manufacturing, we offer products like CVD Tube Furnaces, Muffle Furnaces, and PECVD Systems, with strong deep customization to meet your unique experimental needs. Contact us today to discuss how our expertise can optimize your processes and deliver reliable results!

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- Why are advanced materials and composites important? Unlock Next-Gen Performance in Aerospace, Auto, and More

- What role do CVD tube furnace sintering systems play in 2D material synthesis? Enabling High-Quality Atomic Layer Growth

- Why are CVD tube furnace sintering systems indispensable for 2D material research and production? Unlock Atomic-Scale Precision

- Why is the tube design important in CVD furnaces? Ensure Uniform Deposition for High-Quality Films

- What types of atmosphere control does a CVD Tube Furnace support? Master Vacuum and Gas Control for Precision