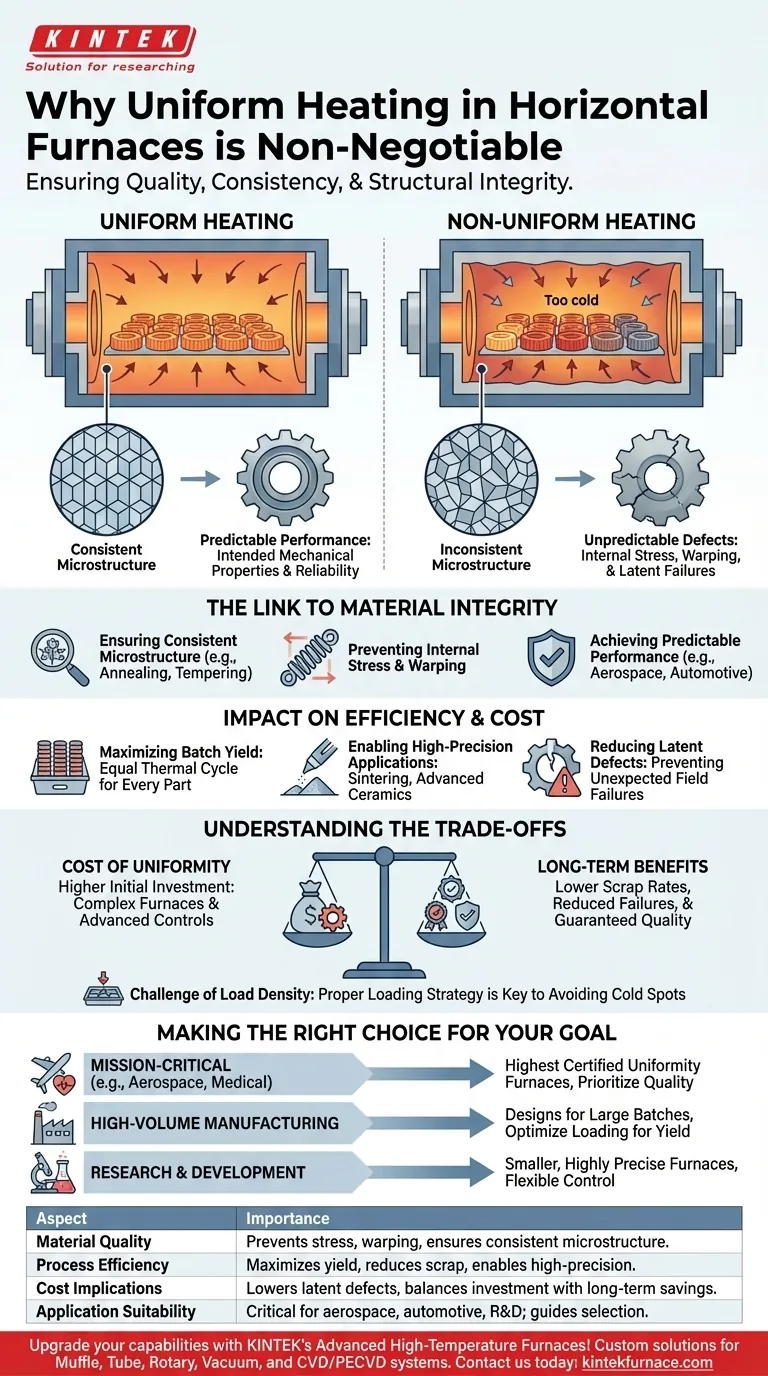

Uniform heating in a horizontal furnace is non-negotiable because it directly determines the quality, consistency, and structural integrity of the processed materials. Without it, critical heat treatment processes like annealing or hardening become unreliable, resulting in components that fail to meet their required performance specifications.

The core issue is that uneven temperatures create internal stresses and inconsistencies in a material's microstructure. This directly compromises the final product's strength and reliability, turning a precision process into a source of unpredictable defects.

The Link Between Temperature and Material Integrity

True heat treatment is about controlling a material's properties at a microscopic level. Temperature uniformity is the primary tool to achieve this control consistently across an entire component or batch.

Ensuring a Consistent Microstructure

Many heat treatment processes, like annealing or tempering, are designed to create a specific crystalline structure within a metal. This microstructure dictates properties like hardness, ductility, and fatigue resistance. If one part of a component is 20 degrees hotter than another, it receives a fundamentally different treatment, resulting in an inconsistent and unreliable final product.

Preventing Internal Stress and Warping

When a material is heated and cooled, it expands and contracts. If this happens unevenly, different sections of the material fight against each other, building up internal stress. This stress can cause immediate warping and distortion or, worse, create microscopic cracks that lead to premature failure under load.

Achieving Predictable Performance

For components used in high-stress applications like aerospace or automotive parts, performance is not optional. Uniform heating ensures that every part of the component has the intended mechanical properties. This predictability is the foundation of modern engineering and quality assurance.

The Impact on Process Efficiency and Cost

Beyond the quality of a single part, temperature uniformity has significant financial implications for any industrial operation.

Maximizing Batch Yield

Horizontal furnaces are often chosen for their ability to process large volumes. Uniform heating ensures that every part in that large batch—whether at the front, back, middle, or edge—receives the exact same thermal cycle. This maximizes yield and minimizes a costly scrap rate.

Enabling High-Precision Applications

Processes like the sintering of powdered metals or the creation of advanced ceramics operate within extremely narrow temperature windows. Uniform heating is not just a benefit; it is a prerequisite for these applications. Without it, the process simply will not work.

Reducing Latent Defects

A component warped by non-uniform heating is easy to spot and reject. The more dangerous outcome is a part that appears fine but is riddled with internal stress. This latent defect can cause the part to fail unexpectedly in service, leading to equipment damage or safety incidents.

Understanding the Trade-offs

Achieving perfect uniformity is a constant balancing act between ideal physics and practical constraints. Understanding these challenges is key to making informed decisions.

The Cost of Uniformity

A furnace engineered for high temperature uniformity is a more complex machine. It requires higher-quality heating elements, more sophisticated insulation, and advanced control systems. This results in a higher initial capital investment, which must be weighed against the long-term cost of defects and inconsistency.

The Challenge of Load Density

A furnace may be certified for excellent uniformity when empty, but the real-world result depends on the workload. Loading too many parts too close together can create cold spots and obstruct heat flow, negating the benefits of a well-designed furnace. Proper loading strategy is as important as the equipment itself.

Making the Right Choice for Your Goal

The required level of uniformity depends entirely on your final objective. Use your goal to guide your technical and process decisions.

- If your primary focus is mission-critical components (e.g., aerospace, medical): Prioritize furnaces with the highest certified temperature uniformity across the entire work zone, even at a higher initial cost.

- If your primary focus is high-volume manufacturing: Focus on furnace designs that maintain uniformity across large batch sizes and invest in optimizing your loading procedures to maximize yield.

- If your primary focus is research and development: Select a smaller, highly precise furnace that offers flexible and verifiable temperature control to explore narrow processing windows for new materials.

Ultimately, treating thermal uniformity as a critical process parameter is the key to transforming raw materials into reliable, high-performance products.

Summary Table:

| Aspect | Importance |

|---|---|

| Material Quality | Prevents internal stress, warping, and ensures consistent microstructure for reliable performance. |

| Process Efficiency | Maximizes batch yield, reduces scrap rates, and enables high-precision applications like sintering. |

| Cost Implications | Lowers latent defects, minimizes equipment failures, and balances initial investment with long-term savings. |

| Application Suitability | Critical for aerospace, automotive, and R&D; guides furnace selection based on uniformity needs. |

Upgrade your lab's capabilities with KINTEK's advanced high-temperature furnaces! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental requirements, enhancing material quality and process efficiency. Don't let non-uniform heating hold you back—contact us today to discuss how our furnaces can transform your heat treatment processes and deliver reliable, high-performance results for your specific applications!

Visual Guide

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What is a quartz tube furnace and what is its primary use? Essential for Controlled High-Temp Processing

- What are the key features of a quartz tube furnace? Discover High-Temp Precision for Your Lab

- What is the necessity of using vacuum-sealed quartz tubes? Ensuring Integrity in Ti-Cu Alloy Heat Treatment

- What factors should be considered when purchasing a quartz tube furnace? Ensure Reliable High-Temperature Processing

- How should a quartz tube furnace be cleaned? Essential Steps for Safe, Contamination-Free Maintenance