Proper cleaning of a quartz tube furnace is a critical maintenance procedure that hinges on using the correct materials and methods. The standard approach involves using a soft, lint-free cloth with a mild solvent, but the specific technique must be chosen carefully to avoid damaging the tube or contaminating future experiments. Always consult the furnace manufacturer's instructions as your primary guide.

The core principle of cleaning a quartz tube is to remove contaminants without compromising the tube's structural integrity. This means avoiding thermal shock, physical abrasions, and harsh chemicals that could etch the surface, as any damage can lead to catastrophic failure at high temperatures.

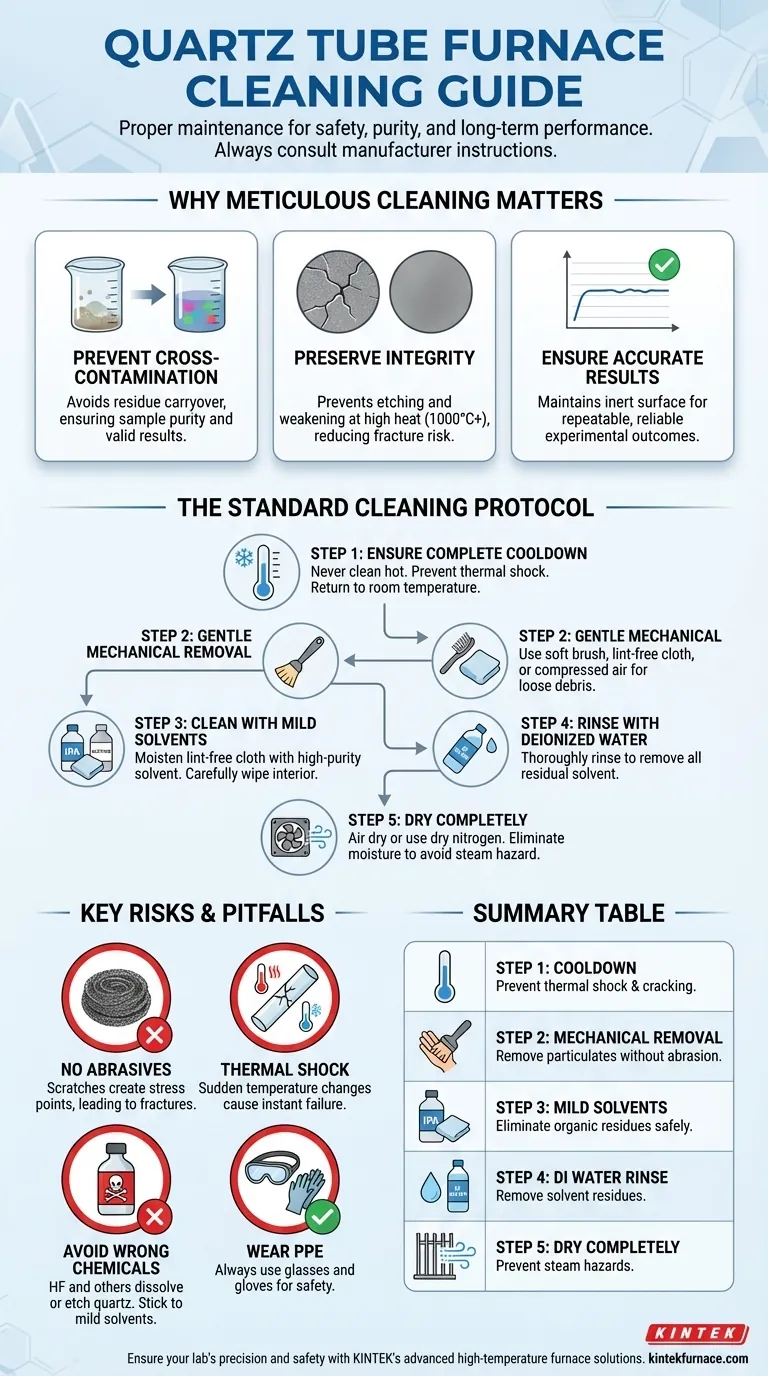

Why Meticulous Cleaning is Non-Negotiable

A quartz tube is more than just a container; it's a high-purity reaction vessel. Failing to maintain its cleanliness has direct consequences for both safety and experimental outcomes.

Preventing Cross-Contamination

Residue left from a previous process can vaporize or react during the next heating cycle. This introduces unintended variables, compromising the purity of your sample and the validity of your results.

Preserving the Quartz Tube's Integrity

At temperatures exceeding 1000°C, even small amounts of certain contaminants can act as a flux, chemically etching or weakening the quartz. This creates stress points that can cause the tube to crack or fail under thermal or mechanical stress.

Ensuring Accurate and Repeatable Results

The chemical inertness of quartz is one of its key features. A clean surface ensures that your process—be it annealing, sintering, or a chemical reaction—interacts only with the intended materials, leading to reliable and repeatable outcomes.

The Standard Cleaning Protocol

Follow this general procedure, always prioritizing the specific instructions provided by your equipment manufacturer.

Step 1: Ensure Complete Cooldown

Never attempt to clean a warm or hot quartz tube. The rapid temperature change from a solvent or cloth will induce thermal shock, causing the tube to crack instantly. Allow the furnace and tube to return fully to room temperature.

Step 2: Gentle Mechanical Removal

For loose particulates or soot, start with the least aggressive method. Use a soft, long-handled brush or a lint-free cloth to gently wipe or push out loose debris. Compressed air or nitrogen can also be effective.

Step 3: Cleaning with Mild Solvents

For organic residues, oils, or fingerprints, moisten a lint-free cloth with a high-purity solvent like isopropyl alcohol (IPA) or acetone. Carefully wipe the interior of the tube. Never pour solvent directly into the tube unless it is part of a specific, documented procedure.

Step 4: Rinse with Deionized Water

After using a solvent, it is crucial to rinse the tube thoroughly with deionized (DI) water. This removes any residual solvent that could otherwise interfere with your next process.

Step 5: Dry Completely

The tube must be absolutely dry before it is heated again. Any trapped moisture can turn to high-pressure steam, creating a significant safety hazard. Allow it to air dry in a clean environment or use a gentle flow of dry nitrogen.

Understanding the Key Risks and Pitfalls

Mistakes during cleaning are a primary cause of quartz tube failure. Being aware of the risks is essential for extending the life of your equipment.

The Danger of Abrasives

Never use abrasive materials like steel wool, scrub pads, or abrasive powders. Scratches on the quartz surface act as stress concentration points, dramatically increasing the likelihood of fracture during heating or cooling.

The Risk of Thermal Shock

This is the most common cause of immediate tube failure. Any sudden, localized temperature change on the quartz surface can and will cause it to crack. Always handle the tube with care and ensure uniform temperature changes.

Choosing the Wrong Chemicals

While quartz is highly inert, it is susceptible to attack by certain chemicals, especially at elevated temperatures. Hydrofluoric acid and hot phosphoric acid will rapidly dissolve it, and strong alkalis can cause etching. Stick to approved mild solvents.

Overlooking Personal Protective Equipment (PPE)

Always wear appropriate safety glasses and gloves. Solvents can be flammable and harmful, and even a cooled tube may have sharp edges if it has been previously damaged.

Making the Right Choice for Your Goal

Your cleaning strategy should be tailored to the nature of the contamination and your operational needs.

- If your primary focus is routine cleaning of light organic residue: A simple wipe-down with isopropyl alcohol on a lint-free cloth, followed by a DI water rinse and thorough drying, is sufficient.

- If your primary focus is removing loose dust or particulates: Begin with a soft brush or a gentle stream of dry, compressed nitrogen or air before moving to solvents.

- If you are dealing with stubborn inorganic or metallic films: You must consult the manufacturer's documentation for advanced cleaning procedures, which may involve dilute acids and require extreme caution and expertise.

Proper maintenance is the foundation of safe and effective operation for any high-temperature furnace.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1 | Ensure complete cooldown | Prevent thermal shock and cracking |

| 2 | Gentle mechanical removal | Remove loose particulates without abrasion |

| 3 | Clean with mild solvents | Eliminate organic residues and oils safely |

| 4 | Rinse with deionized water | Remove solvent residues to avoid contamination |

| 5 | Dry completely | Prevent steam hazards and ensure safety |

Ensure your lab's precision and safety with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with strong deep customization to meet your unique experimental needs. Contact us today for expert guidance and reliable equipment that enhances your research outcomes!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety