At its core, a quartz tube furnace is a specialized piece of laboratory equipment defined by its ability to provide extremely high and uniform heat within a chemically non-reactive, transparent environment. Its key features are its high-temperature capability (often exceeding 1000°C), the chemical inertness of the quartz tube, the ability to visually monitor processes in real-time, and its capacity for precise atmospheric and thermal control.

A tube furnace is not just a high-temperature oven; it is a complete system designed to create a perfectly controlled and isolated micro-environment. Understanding its features is about understanding how to manipulate temperature, atmosphere, and purity for processing sensitive materials.

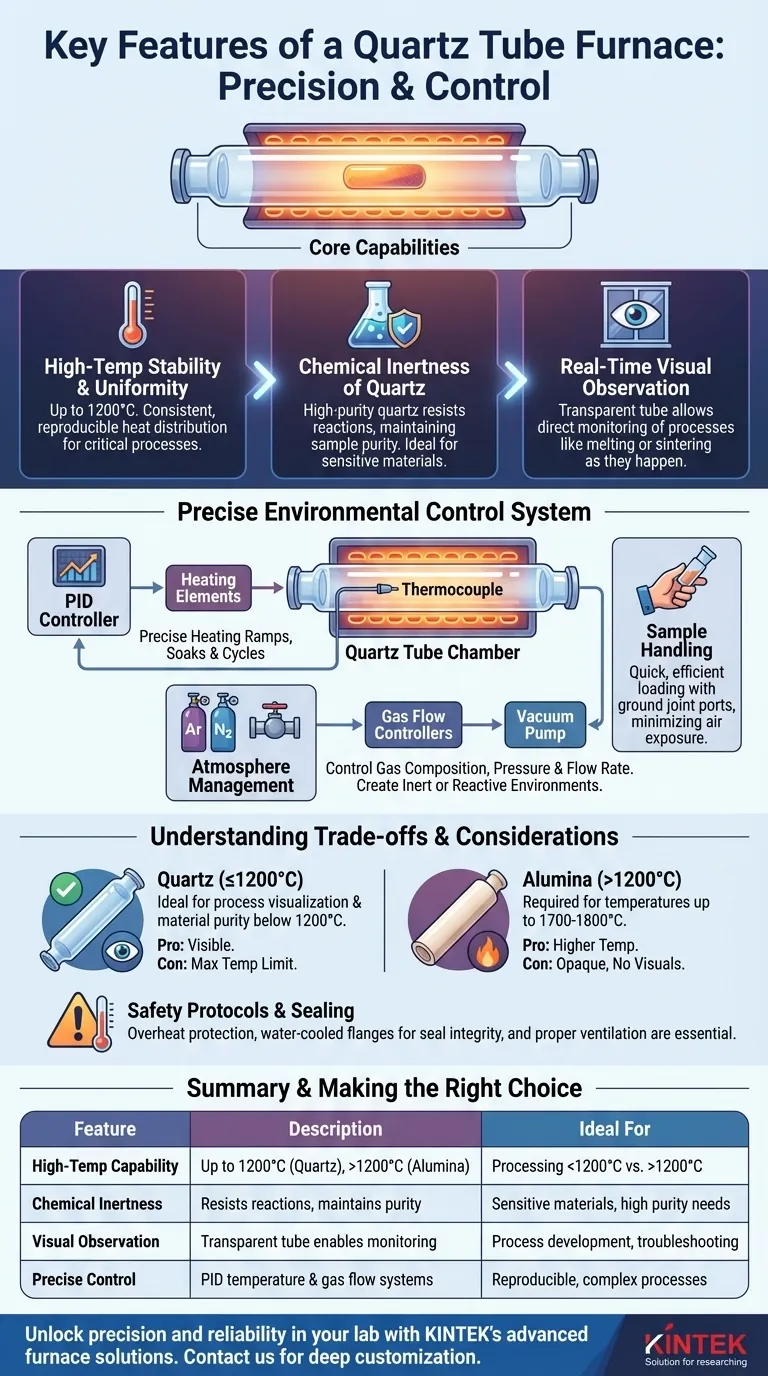

The Core Capabilities of a Quartz Tube Furnace

A quartz tube furnace's primary value comes from a unique combination of thermal performance and material properties. These features work together to enable processes that are impossible in standard ovens or other heating equipment.

High-Temperature Stability and Uniformity

The furnace is designed to reach and maintain very high temperatures, frequently up to 1200°C. Critically, the heating elements are arranged to ensure thermal uniformity along the length of the processing zone inside the tube.

This uniformity is essential for achieving consistent and reproducible results, whether you are annealing a wafer, growing a crystal, or performing a chemical synthesis.

The Chemical Inertness of Quartz

The use of a high-purity quartz tube is a defining feature. Quartz (fused silica) is highly resistant to thermal shock and is chemically inert, meaning it will not react with the vast majority of materials being processed.

This ensures that the sample's purity is maintained, which is critical in semiconductor research, catalyst development, and other fields where contamination can compromise results.

Real-Time Visual Observation

Unlike opaque ceramic or metal furnaces, the transparency of the quartz tube allows for direct, real-time observation of the sample during the heating process.

This visual feedback is invaluable for process development, troubleshooting, and educational purposes. Researchers can watch for color changes, melting, sintering, or other physical transformations as they happen.

A System for Precise Environmental Control

A modern tube furnace is more than its heating chamber and tube. It is an integrated system where each component contributes to creating a tightly controlled processing environment.

Temperature Control Systems

Precise heating is managed by a digital PID (Proportional-Integral-Derivative) controller. This unit receives feedback from a thermocouple placed near the sample and adjusts power to the heating elements to follow a programmed temperature profile with high accuracy.

This allows for controlled heating ramps, extended soaks at a specific temperature, and controlled cooling cycles.

Atmosphere Management

Most applications require control over the gaseous environment inside the tube. This is achieved using a system of flanges, seals, valves, and gas flow controllers.

These components allow you to flow inert gases like argon or nitrogen to prevent oxidation, introduce reactive gases for chemical vapor deposition (CVD), or create a vacuum using a pump. The system can be configured to precisely manage gas composition, pressure, and flow rate.

Sample Handling and Throughput

Modern designs emphasize user convenience. Features like ground joint connection ports and well-designed sealing flanges allow for quick and easy loading and unloading of samples.

This design not only improves efficiency but also minimizes the time the internal environment is exposed to ambient air, preserving process integrity.

Understanding the Trade-offs and Considerations

While powerful, a quartz tube furnace is not the right tool for every application. Making an informed choice requires understanding its limitations and alternatives.

Quartz vs. Alumina: Choosing Your Tube

The primary limitation of a quartz tube is its maximum service temperature, typically around 1200°C. For processes requiring even higher temperatures (up to 1700-1800°C), an alumina tube is the necessary alternative.

The trade-off is visibility. Alumina is opaque, so you lose the ability to visually monitor the process. Alumina may also be more reactive with certain materials than quartz is.

Sealing and System Integrity

Achieving a perfect vacuum or a completely pure gas environment depends entirely on the quality of the seals and flanges. Silicone O-rings can degrade at high temperatures, which is why some systems include a recirculating water chiller to cool the flange area.

Maintaining the integrity of these seals is a critical aspect of operation, especially for highly sensitive processes.

Safety Protocols at High Temperatures

Operating at temperatures above 1000°C introduces significant safety risks. Essential safety features include overheat protection to shut the furnace down in case of controller failure.

Proper user training, personal protective equipment (PPE), and adequate ventilation are non-negotiable for safe operation.

Making the Right Choice for Your Application

Your choice of furnace configuration should be driven directly by the demands of your experimental or production goals.

- If your primary focus is process visualization and material purity below 1200°C: A quartz tube furnace is the ideal choice due to its transparency and inertness.

- If your primary focus is achieving the highest possible temperatures (above 1200°C): You must opt for a furnace system equipped with an alumina tube, sacrificing visual observation for thermal capability.

- If your primary focus is working with reactive gases or high vacuum: Prioritize the quality of the sealing flanges, mass flow controllers, and vacuum system to ensure precise environmental control.

By understanding these core features and trade-offs, you can select and configure a tube furnace system that provides the exact environment your work requires.

Summary Table:

| Feature | Description |

|---|---|

| High-Temperature Capability | Reaches up to 1200°C with uniform heating for consistent results |

| Chemical Inertness | Quartz tube resists reactions, maintaining sample purity |

| Real-Time Visual Observation | Transparent tube allows monitoring of processes during heating |

| Precise Temperature Control | PID controllers enable accurate heating ramps and soaks |

| Atmosphere Management | Gas flow and vacuum systems for controlled environments |

| Sample Handling | Easy loading/unloading with ground joint ports for efficiency |

Unlock precision and reliability in your lab with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored quartz tube furnaces, muffle furnaces, tube furnaces, rotary furnaces, vacuum & atmosphere furnaces, and CVD/PECVD systems. Our strong deep customization capability ensures we meet your unique experimental needs for superior thermal and atmospheric control. Contact us today to discuss how we can enhance your research and production processes!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis