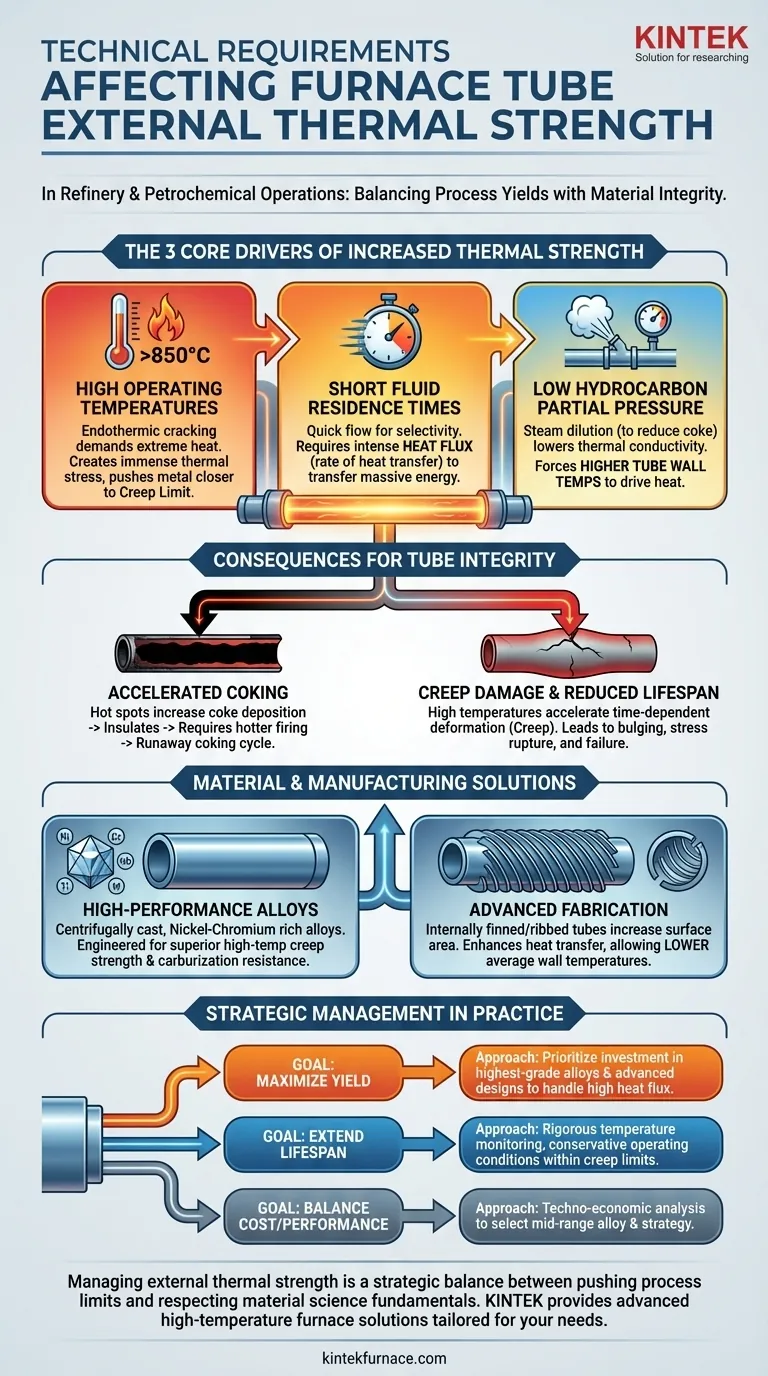

In refinery and petrochemical operations, the external thermal strength of furnace tubes is most significantly affected by three core technical requirements of the process itself: high operating temperatures, short fluid residence times, and low hydrocarbon partial pressures. These conditions, driven by the need for higher efficiency and yield in processes like steam cracking, combine to place an immense heat load on the tube material, demanding superior alloys and advanced manufacturing to prevent premature failure.

The push for greater process yields directly translates into harsher operating conditions. This intensifies the thermal load, or "thermal strength," on furnace tubes, turning the selection of materials and process management into a critical exercise in balancing performance against material integrity.

The Core Drivers of Increased Thermal Strength

To understand why thermal strength increases, we must examine the process goals that dictate furnace operating conditions. The drive for higher yields in processes like ethylene production forces engineers to push these three specific variables.

The Demand for High Process Temperatures

Cracking hydrocarbons into more valuable products like ethylene is an endothermic reaction that is favored at very high temperatures, often exceeding 850°C (1560°F).

To achieve this process fluid temperature, the external surface of the furnace tube must be significantly hotter. This high temperature differential creates immense thermal stress and pushes the tube metal closer to its creep limit, the point at which it begins to permanently deform under load.

The Principle of Short Residence Time

For many cracking reactions, selectivity is key. To maximize the yield of desired products (like ethylene) and minimize unwanted secondary reactions, the process fluid must pass through the hottest part of thefurnace very quickly, often in fractions of a second.

To transfer the massive amount of energy required for the reaction in such a short time, the heat flux (the rate of heat transfer per unit area) must be extremely high. This intense heat flux is the primary contributor to what is defined as high external thermal strength.

The Role of Low Hydrocarbon Partial Pressure

To further improve selectivity and suppress the formation of coke—a carbonaceous deposit that fouls tubes—steam is injected into the hydrocarbon feed. This practice, known as steam dilution, lowers the partial pressure of the hydrocarbons.

While this is beneficial for the process chemistry, it also means the process fluid has a lower density and thermal conductivity. This can require an even higher tube wall temperature to drive the necessary heat into the fluid, further increasing the thermal load on the tube material.

Consequences for Furnace Tube Integrity

Operating under conditions of high thermal strength has direct and severe consequences for the physical health and lifespan of the furnace tubes.

Accelerated Coking

Higher tube wall temperatures create a vicious cycle. Hot spots on the tube wall accelerate the rate of coke deposition. This coke layer acts as an insulator, forcing operators to fire the furnace harder and raise the tube temperature even further to get the required heat into the process fluid, leading to runaway coking.

Creep Damage and Reduced Lifespan

Creep is the slow, time-dependent deformation of a material under stress at high temperatures. High thermal strength directly translates to higher tube metal temperatures, which dramatically accelerate the rate of creep.

Over time, this leads to measurable tube bulging and, eventually, stress rupture and failure. The lifespan of a furnace tube is almost entirely dictated by its resistance to creep damage under its specific operating conditions.

Understanding the Trade-offs

The demands placed on furnace tubes create an inherent conflict between operational goals and material limitations. Recognizing these trade-offs is fundamental to safe and profitable plant operation.

Process Efficiency vs. Material Longevity

There is a direct and unavoidable trade-off between maximizing process yield and extending the life of the furnace tubes. Pushing for higher cracking severity through high temperatures and short residence times will always increase the rate of creep damage and shorten the replacement cycle. This is a critical economic and risk-management decision.

The Paradox of Steam Dilution

While steam dilution is a key tool for mitigating coke formation, it complicates heat transfer dynamics. If not managed carefully with furnace firing and process flow, the lower thermal conductivity of the steam-rich fluid can inadvertently lead to higher-than-expected tube metal temperatures, partially negating its benefits and still contributing to creep.

Material and Manufacturing Solutions

The challenge of high thermal strength has driven significant innovation in both metallurgy and manufacturing techniques, as noted by the necessity for specialized materials and skills.

The Shift to High-Performance Alloys

Modern furnace tubes have moved far beyond simple stainless steels. They are now made from centrifugally cast high-performance alloys rich in nickel and chromium (e.g., HP and HK series), with additions of elements like niobium, titanium, and tungsten.

These advanced alloys are specifically engineered for superior high-temperature creep strength and resistance to carburization—a mechanism where carbon from the process fluid embrittles the tube metal.

Advanced Casting and Fabrication

The reference to "advanced cast pipe skills" points to critical manufacturing processes. Centrifugal casting is used to produce a dense, uniform tube with a favorable grain structure for resisting creep.

Furthermore, techniques for creating internally finned or ribbed tubes are employed. These features increase the internal surface area, enhancing heat transfer to the process fluid. This allows the required heat input to be achieved at a lower average tube wall temperature, thereby reducing thermal stress and extending the tube's life.

How to Manage Furnace Tube Strength in Practice

Your approach to managing thermal strength should align directly with your primary operational goal.

- If your primary focus is maximizing yield and throughput: Prioritize investment in the highest-grade alloys and advanced tube designs (like internal fins) to safely handle the required high heat flux.

- If your primary focus is extending furnace lifespan and reliability: Implement rigorous monitoring of tube metal temperatures and consider slightly more conservative operating conditions to stay well within the material's creep design limits.

- If your primary focus is balancing performance and cost: Conduct a detailed techno-economic analysis to select a mid-range alloy and operating strategy that provides an acceptable return on investment without compromising safety.

Ultimately, managing the external thermal strength of furnace tubes is a strategic balance between pushing process limits and respecting material science fundamentals.

Summary Table:

| Factor | Impact on Thermal Strength |

|---|---|

| High Operating Temperatures | Increases thermal stress and creep risk |

| Short Fluid Residence Times | Raises heat flux, intensifying thermal load |

| Low Hydrocarbon Partial Pressures | Can elevate tube wall temperatures |

Struggling with furnace tube failures under extreme heat? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for refinery and petrochemical labs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is backed by strong deep customization capabilities to precisely meet your unique experimental needs. Enhance your process efficiency and extend equipment lifespan—contact us today for a consultation!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- How is a high-precision laboratory balance installed in a tube furnace? Master Thermal Isolation for Precise Data

- What precaution should be taken when moving a vacuum tube furnace? Avoid Costly Damage and Safety Risks

- What is the significance of the slow cooling process in a high-temperature tube furnace? Master TMD Synthesis Quality

- How does the design of a dual-zone Tube Furnace facilitate precise metal phosphide conversion? Optimize Heterojunctions

- Why Use Argon in Tube Furnaces for Titania Nanotubes? Optimize Charge Transport & Hydrogen Production

- Why is a tube annealing furnace used for SiC hydrogenation? Unlock Pure Atomic Surfaces for Superior Crystal Bonding

- How do dual-zone tube furnaces facilitate the growth of BiRe2O6 single crystals? Precision Gradient Control Explained

- How does a tube furnace ensure a controlled reaction environment? Achieve Precise Isothermal Oxidation Results