At its core, the work process of a quartz tube furnace involves placing a sample into a sealed tube, precisely controlling the temperature and atmospheric environment, and then allowing it to cool under controlled conditions. This method is fundamental for creating and treating advanced materials where purity and structural integrity are paramount.

A quartz tube furnace is more than just an oven; it is a self-contained, highly controlled environment. Its primary function is to isolate a sample from unwanted atmospheric reactions while subjecting it to a precise and uniform thermal cycle.

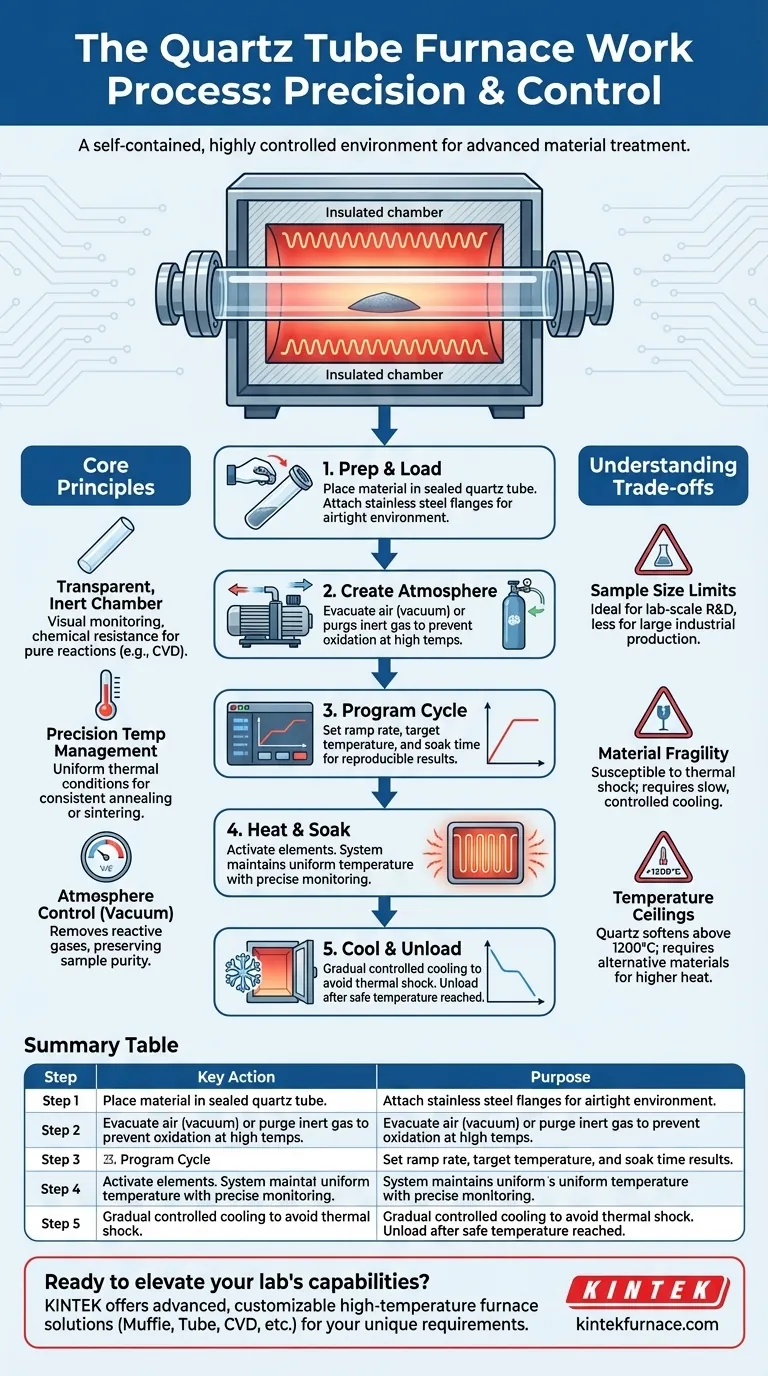

Deconstructing the Workflow: A Step-by-Step Guide

The operation of a quartz tube furnace follows a deliberate, multi-stage process designed for precision and repeatability. Each step serves a critical function in achieving the desired material properties.

Step 1: Preparation and Sample Loading

Before heating begins, the material or sample is carefully placed inside the quartz tube. The tube itself acts as the reaction chamber. For processes requiring a vacuum or a specific gas, stainless steel sealing flanges are attached to both ends of the tube to ensure an airtight environment.

Step 2: Creating the Controlled Atmosphere

Once sealed, the environment inside the tube is modified. A vacuum pump may be used to evacuate the air, preventing the sample from oxidizing or reacting with atmospheric gases at high temperatures. Alternatively, specific inert or reactive gases can be purged into the tube.

Step 3: Programming the Thermal Cycle

Using the furnace's control system, the operator sets the target temperature, the rate of temperature increase (the ramp rate), and the duration the furnace will hold its maximum temperature (the soak time). This programmability is key to reproducible results.

Step 4: The Heating and Soaking Phase

The heating elements surrounding the quartz tube are activated. The control system continuously monitors the temperature and adjusts power to follow the programmed profile precisely. Features like double-wall insulation minimize heat loss, ensuring energy efficiency and temperature stability.

Step 5: Controlled Cooling and Unloading

After the soaking phase is complete, the heating elements are turned off. The furnace is left to cool down gradually to room temperature. This controlled cooling is crucial to prevent thermal shock, which could crack the quartz tube or damage the sample. Only after it is cool is it safe to vent the system and remove the processed material.

The Core Principles of Operation

Understanding why a quartz tube furnace works the way it does is key to using it effectively. Its design is based on a few fundamental principles that enable high-performance materials processing.

The Quartz Tube: A Transparent, Inert Chamber

Quartz is used because it is chemically inert, meaning it will not react with most substances even at extreme temperatures. Its transparency is a unique advantage, allowing researchers to visually monitor the process in real time, which is invaluable for applications like Chemical Vapor Deposition (CVD).

Precision Temperature Management

The furnace's ability to achieve and maintain a uniform temperature is critical. A sophisticated control system continuously measures the heat inside the chamber and makes micro-adjustments, ensuring that the entire sample experiences the exact same thermal conditions for processes like annealing or sintering.

Atmosphere Control: The Vacuum Advantage

Operating in a vacuum or a specific gas environment is a primary feature. Removing oxygen and other reactive gases from the air prevents unwanted chemical changes in the sample, preserving its purity and intended properties.

Understanding the Trade-offs

While powerful, a quartz tube furnace is a specialized tool with inherent limitations that you must consider.

Limitation: Sample Size and Throughput

The diameter of the quartz tube naturally limits the size and volume of the sample that can be processed at one time. This makes it ideal for lab-scale research and development but less suited for large-scale industrial production.

Limitation: Material Fragility

Quartz is a form of glass and is inherently brittle. It is susceptible to cracking from mechanical impact or rapid temperature changes (thermal shock). This necessitates careful handling and adherence to slow, controlled cooling cycles.

Limitation: Temperature Ceilings

While capable of exceeding 1000°C, quartz begins to soften at very high temperatures (typically above 1200°C). For applications requiring even higher heat, alternative ceramic tubes, such as alumina or corundum, must be used.

Making the Right Choice for Your Goal

Select your operational focus based on the primary objective of your experiment.

- If your primary focus is materials synthesis (e.g., CVD): Prioritize creating a pure, controlled atmosphere by properly sealing the tube and using a vacuum or high-purity gas.

- If your primary focus is heat treatment (e.g., annealing): Leverage the programmable controller to design a precise thermal cycle with controlled ramp and cooling rates for optimal material structure.

- If your primary focus is exploratory research: Take advantage of the transparent quartz tube to visually observe reactions, phase changes, or melting behavior in real time.

Mastering the workflow of a quartz tube furnace empowers you to precisely engineer the properties of advanced materials.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1 | Sample Loading | Place material in quartz tube with sealing flanges |

| 2 | Atmosphere Control | Evacuate air or purge gases to prevent oxidation |

| 3 | Thermal Programming | Set ramp rate, temperature, and soak time |

| 4 | Heating Phase | Activate elements for uniform temperature control |

| 5 | Cooling Phase | Gradual cool-down to avoid thermal shock |

Ready to elevate your lab's capabilities with a customized quartz tube furnace? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for materials synthesis, heat treatment, and more. Contact us today to discuss how we can optimize your processes and deliver reliable, tailored results!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- How is a high-temperature tube furnace utilized in the synthesis of MoO2/MWCNTs nanocomposites? Precision Guide

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab