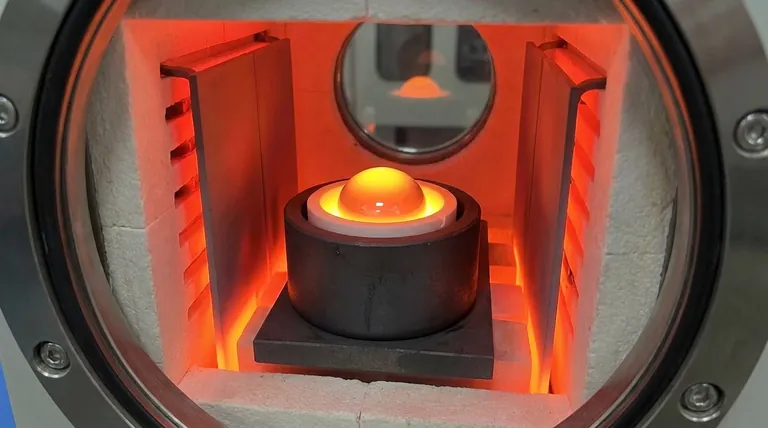

In high-temperature vacuum furnace experiments, the graphite crucible functions primarily as a robust structural carrier and a critical component of the thermal insulation system. It physically supports the alloy specimen and ceramic (Al2O3) shell assembly while simultaneously regulating the thermal environment to ensure consistent experimental conditions.

The graphite crucible is not merely a container; it is an active thermal stabilizer that enables the formation of precise hemispherical alloy droplets by maintaining a uniform temperature field at extremes exceeding 1550°C.

The Role of Structural Support

Acting as the Specimen Carrier

The primary function of the graphite crucible is to serve as the physical carrier for the experimental setup. It holds both the alloy specimen and the Al2O3 shell assembly securely in place.

Stability at Extreme Temperatures

Graphite is selected for its exceptional high-temperature stability. It maintains structural integrity at temperatures of 1550°C to 1600°C, ensuring the experimental geometry remains fixed throughout the heating process.

Thermal Regulation and Uniformity

acting as Thermal Insulation Shielding

Beyond physical support, the crucible acts as part of the furnace's thermal insulation shielding. This role is vital for isolating the experimental zone from fluctuating thermal gradients.

Ensuring a Uniform Temperature Field

By functioning as a thermal shield, the crucible helps generate a highly uniform temperature field around the sample. This uniformity prevents localized hot or cold spots that could skew interaction data.

Facilitating Proper Droplet Formation

The uniform thermal environment enabled by the crucible allows the alloy to melt evenly. This results in the formation of a regular, consistent hemispherical droplet, which is essential for accurate analysis of the alloy-shell interaction.

Understanding the Trade-offs

The Risk of Chemical Interaction

While graphite is thermally stable, it is chemically active in certain environments due to its reductive properties. As noted in supplementary contexts, graphite can act as a reducing agent at high temperatures.

Potential for Sample Contamination

In sensitive experiments, there is a risk that the carbon from the crucible could interact with the alloy or the ceramic shell. You must verify that the "reductive atmosphere" created by the graphite does not introduce unwanted variables into your specific alloy/ceramic interaction study.

Ensuring Experimental Accuracy

To effectively utilize a graphite crucible in your vacuum furnace experiments, consider the following:

- If your primary focus is thermal precision: Rely on the graphite crucible to shield the zone and create the uniform heat required for perfect droplet shape.

- If your primary focus is chemical purity: Monitor the interface for carbon contamination, as the graphite's reductive nature can unintentionally alter the alloy or shell composition.

The graphite crucible is the linchpin of the thermal zone, converting the raw heat of the furnace into a controlled environment suitable for precision measurement.

Summary Table:

| Feature | Function in Interaction Experiments | Benefit to Researcher |

|---|---|---|

| Structural Carrier | Supports alloy specimen and Al2O3 shell | Maintains geometric stability at 1550°C+ |

| Thermal Shielding | Acts as insulation within the furnace | Creates a uniform temperature field for droplets |

| Thermal Stability | Resists deformation at extreme heat | Ensures consistent, repeatable experimental conditions |

| Chemical Nature | Provides a reductive atmosphere | Enables specific interaction studies (requires contamination monitoring) |

Elevate Your Material Research with KINTEK

Precision in high-temperature experiments starts with the right equipment. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all of which can be customized to your specific alloy or ceramic research needs.

Whether you require specialized graphite components or a complete high-temp furnace setup, our team is ready to deliver the reliability your laboratory demands. Contact us today to discuss your unique requirements and see how our tailored solutions can enhance your experimental accuracy.

References

- Guangyao Chen, Chonghe Li. Effect of Kaolin/TiO2 Additions and Contact Temperature on the Interaction between DD6 Alloys and Al2O3 Shells. DOI: 10.3390/met14020164

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the advantages of nickel crucibles for KOH activation? Ensure High Purity & Thermal Stability up to 700°C

- Why is ASTM A36 steel plate used for heat treatment furnace frameworks? Reliable Strength & Cost-Efficiency

- What is the necessity of an observation window in a magnesium combustion chamber? Elevate Your Visual Data Analysis

- What role does a laboratory oven play in the evaluation of the physical properties of teak activated carbon? Accuracy Tips

- How does a high-pressure reaction kettle facilitate 3D core-shell formation? Mastering Hydrothermal Catalyst Synthesis

- What functions do high-purity graphite crucibles serve in tantalum carbide synthesis? Essential Thermal & Chemical Roles

- Why are desiccators containing saturated salt solutions used when evaluating the hygroscopicity of modified wood?

- Why must high-pressure microwave reaction vessels maintain excellent sealing performance? Ensure Carbon Synthesis Success