The integrity of the vessel's seal is the defining factor for successful carbon nanosphere synthesis. Because reaction temperatures are frequently set at 180°C or higher, the vessel must withstand and contain the immense internal pressure generated by solvents, such as deionized water, to ensure both reaction completion and operator safety.

A hermetic seal is required to maintain the specific high-temperature, high-pressure environment necessary for the dehydration and carbonization of glucose. Without it, the necessary internal pressure cannot build, rendering the synthesis impossible and the laboratory environment unsafe.

The Physics of the Reaction Environment

Reaching Superheated Temperatures

Synthesis protocols for carbon nanospheres often demand temperatures exceeding 180°C. At atmospheric pressure, water boils at 100°C and cannot get hotter in liquid form.

Generating Internal Pressure

To reach 180°C, the solvent (deionized water) must be prevented from boiling away. A perfect seal traps the vapor, causing significant internal pressure to build within the closed space.

Facilitating Chemical Transformation

This high-pressure environment is not a byproduct; it is a catalyst. It drives the thorough dehydration and carbonization of glucose, forcing the molecules to restructure into the desired spherical carbon nanostructures.

Operational Safety and Risks

Containing Volatile Forces

The internal pressure generated by superheated water is substantial. If the seal is compromised, this energy releases uncontrollably.

Ensuring Laboratory Safety

Superior sealing performance is the primary barrier between the operator and a potential hazard. It prevents dangerous leaks of superheated steam and chemical reactants, ensuring laboratory operational safety is maintained throughout the process.

Understanding the Trade-offs

Seal Durability vs. Reaction Intensity

While high pressure is necessary for synthesis, it places immense stress on the vessel's sealing mechanism. Frequent cycling at these temperatures can degrade gaskets and sealing surfaces over time.

Maintenance Requirements

Reliability comes at the cost of vigilance. To maintain the "superior sealing" mandated by the process, users must regularly inspect and replace sealing components, as even a microscopic failure can lead to pressure loss and a failed synthesis batch.

Ensuring Process Success

To maximize yield and safety during carbon nanosphere synthesis, apply the following principles:

- If your primary focus is Reaction Quality: Ensure the vessel is sealed to specification to maintain the pressure required for complete glucose carbonization.

- If your primary focus is Laboratory Safety: Inspect the sealing mechanism before every run to prevent hazardous leaks caused by the 180°C+ operating environment.

Your ability to produce uniform carbon nanospheres relies entirely on your ability to contain the pressure that creates them.

Summary Table:

| Feature | Requirement | Impact on Synthesis |

|---|---|---|

| Temperature | > 180°C | Enables liquid phase to exceed normal boiling point |

| Pressure | High/Hermetic | Catalyzes dehydration and carbonization of glucose |

| Containment | Perfect Seal | Prevents solvent loss and ensures uniform nanostructures |

| Safety | High Integrity | Protects operators from superheated steam and leaks |

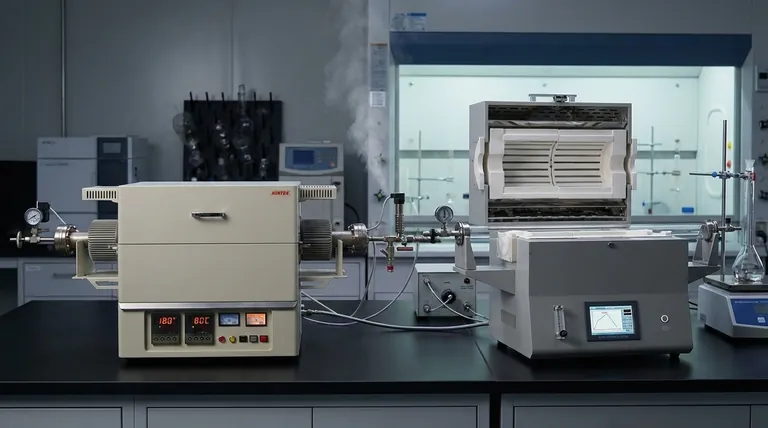

Elevate Your Material Synthesis with KINTEK

Precise carbon nanosphere production demands equipment that never fails under pressure. Backed by expert R&D and world-class manufacturing, KINTEK provides high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, along with customizable lab high-temperature furnaces designed to meet your most rigorous sealing and thermal requirements.

Don't let pressure loss compromise your research or laboratory safety. Contact KINTEK today to find the perfectly sealed solution tailored to your unique synthesis needs!

Visual Guide

References

- Kaihe Lv, Jinsheng Sun. Microwave-Assisted Synthesis of Carbon Nanospheres and Their Application as Plugging Agents for Oil-Based Drilling Fluids. DOI: 10.3390/molecules30030463

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Cylindrical Resonator MPCVD Machine System for Lab Diamond Growth

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- Why is a Pt5%Au crucible required for S53P4 bioactive glass? Ensure Purity at 1400°C

- What is the function of vacuum-sealed quartz jackets in sample encapsulation? Ensure Purity in Material Synthesis

- What is the key role of a vacuum filter in a waste magnesium vacuum distillation system? Protecting Your Pumps from Catastrophic Damage

- Why is a vacuum pump used to evacuate the thermal modification chamber? Ensure Safety and Material Integrity

- What role do graphite molds play in graphite flake alignment? Engineered Precision for High Thermal Conductivity

- What is the necessity of configuring non-contact infrared pyrometers for temperature monitoring? Ensure Sintering Precision

- How do industrial sealing clamps and O-ring systems ensure process repeatability? Achieve Consistent Sintering Quality

- What is the function of high-vacuum encapsulated quartz tubes for Ce2(Fe, Co)17? Ensure Phase Purity and Stability